Operating instructions safety switches nx – EUCHNER NXxxx User Manual

Page 4

Operating Instructions Safety Switches NX...

Correct Use

Safety switches series NX are interlocking devices

without guard locking.

In combination with a separating safety guard, this

safety component prevents dangerous machine

movements from being performed for as long as the

safety guard is open. A stop command is triggered

if the safety guard is opened during the dangerous

machine function.

The safety switches series NX comply with the regu-

lations of EN 60947-5-1 (incl. Annex K) and comply

with the requirements of the employers' liability

insurance associations for machines, installations

and personnel protection.

Before safety switches are used, a risk assessment

must be performed on the machine in accordance

with

EN ISO 13849-1, Safety of machinery. Safety re-

lated parts of control systems. General principles

for design

EN ISO 14121, Safety of machinery. Risk assess-

ment. Principles.

IEC 62061, Safety of machinery – Functional

safety of safety-related electrical, electronic and

programmable electronic control systems.

Correct use includes compliance with the relevant

requirements for installation and operation, in

particular

EN ISO 13849-1, Safety of machinery. Safety re-

lated parts of control systems. General principles

for design

EN 1088, Safety of machinery. Interlocking

devices associated with guards. Principles for

design and selection

EN 60204-1, Safety of machinery. Electrical equip-

ment of machines. General requirements.

Important:

The user is responsible for safe integration of the

device in a safe overall system. For this purpose

the overall system must be validated, e.g. in ac-

cordance with EN ISO 13849-2.

If the simplified method according to section 6.3

EN ISO 13849-1:2008 is used for validation, the

Performance Level (PL) may be reduced if several

devices are connected one after the other.

If a product data sheet is included with the product,

the information on the data sheet applies in case of

discrepancies with the operating instructions.

Safety Precautions

Safety switches perform a personal protection

function. Incorrect installation or tampering can

lead to severe injuries to personnel.

Safety components must not be bypassed

(bridging of contacts), turned away, removed

or otherwise rendered ineffective.

On this topic pay attention in particular to the

measures for reducing the possibility of bypassing

according to EN 1088:1995.A2:2008, sec. 5.7.

The switching operation may only be triggered

by actuators specially provided for this pur-

pose which are permanently connected to the

protective guard.

Mounting, electrical connection and setup only

by authorized personnel.

Function

The safety switch signals that the safety guard is

closed.

The switch does not perform guard locking!

Closing

The safety contacts are closed by inserting the

actuator.

Opening

The safety contacts are positively opened by with-

drawing the actuator.

Installation

Safety switches and actuators must not be used

as an end stop.

Mount the safety switch only in assembled

condition!

Assemble the safety switch so that

access to the switch is difficult for operating per-

sonnel when the safety guard is open.

address programming, inspection and replace-

ment by authorized personnel are possible.

Insert the actuator in the actuating head.

Mount the safety switch positively.

Permanently connect the actuator to the safety

guard so that it cannot be detached, e.g. using

the enclosed non-removable screws, rivets or

welding.

Fit an additional end stop for the movable part of

the safety guard.

Changing the Actuating Direction

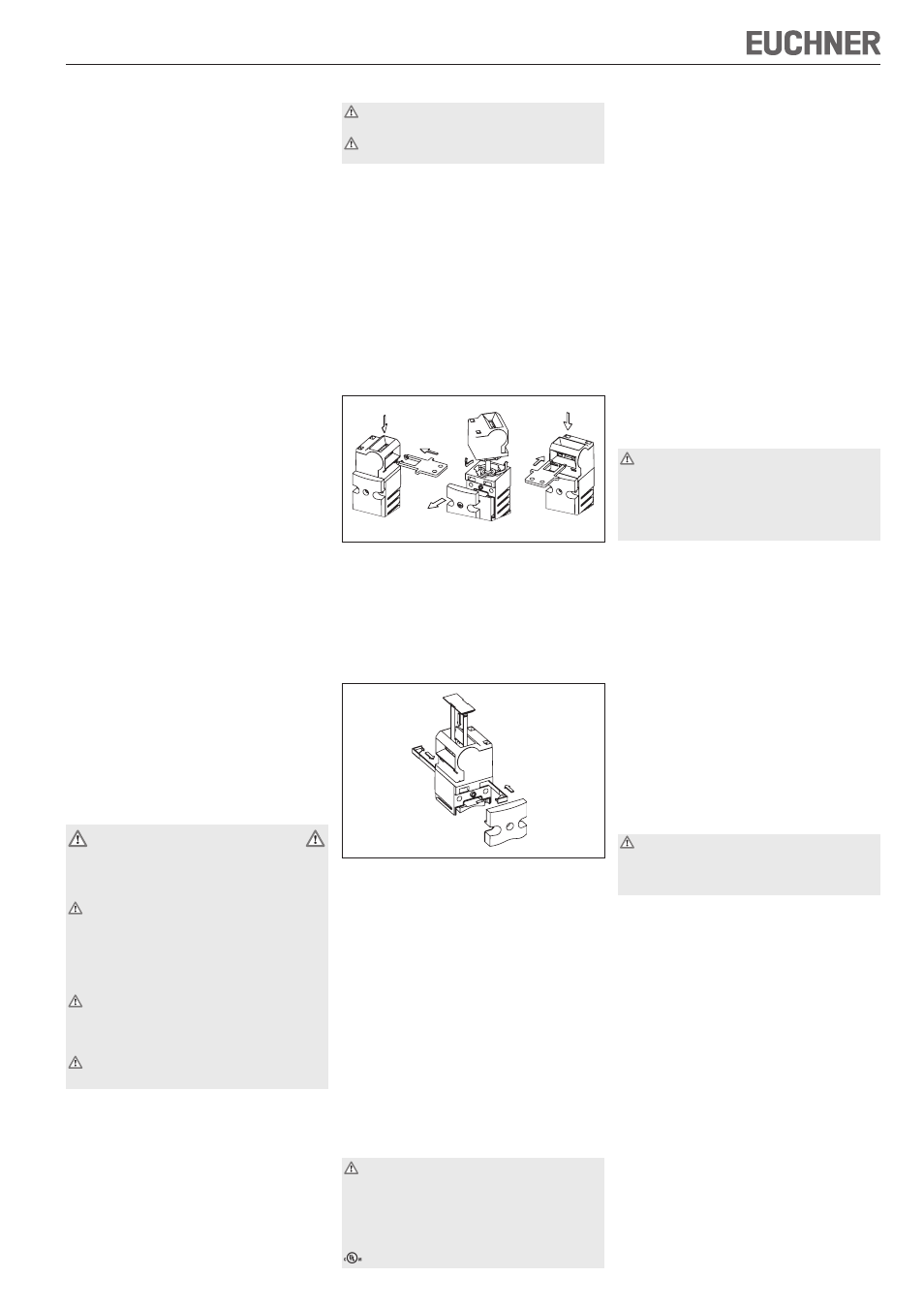

Figure 1: Changing the actuating direction

Unscrew and open switch cover.

Remove actuating head from the switch by turn-

ing and refit in the required position (bayonet

fastening).

Fit locking pins for protection against twisting

(Figure 2). It is then not possible to change the

actuating direction again.

Figure 2: Fitting the locking pins and the slot cover

Close the cover and screw in position.

Cover the unused actuating slot with the enclosed

slot covers (Figure 2).

Protection Against Environmental Influ-

ences

A lasting and correct safety function requires that

the actuating head must be protected against the

penetration of foreign bodies such as swarf, sand,

blasting shot, etc.

Cover the unused actuating slot with the slot

cover.

Cover the actuating slot, the actuator and the rating

plate during painting work!

Only use solvent-free cleaning agents to clean the

switch!

Electrical Connection

When choosing the insulation material and wire

for the connections, pay attention to the over-

temperature in the housing (depending on the

operating conditions)!

For NX without plug connector:

For use and applications as per the requirements of

, copper wire 60/75 °C is to be used.

Version NX1... (cable entry M20x1.5/NPT ½",

see rating plate)

Unscrew locking screw for the required insertion

opening.

Fit cable gland M20x1.5 or NPT½".

Important: To achieve the specified degree of

protection, use a cable gland from EUCHNER (order.

no. 110 132, 110 133 or 110 134).

Conductor cross-section from 0.34 mm² to max.

1.5 mm².

For pin assignment see Figure 3.

Tighten the screws with a torque of 0.6 Nm.

Check that the cable entry is sealed.

Close the cover and screw in position.

Optional LED module L024

Max. outer diameter that can be connected

1.0 mm.

For pin assignment see Figure 4.

Due to the restricted space for wiring, use wires

as thin as possible (recommendation 0.25 mm²)!

Observe current rating of the wire!

Functional Check

Warning! Danger of fatal injury as a result of

faults in installation and functional check.

Before carrying out the functional check, make

sure that there are no persons in the danger

area. Observe the valid accident prevention

regulations.

After installation and any fault, the safety function

must be fully checked. Proceed as follows:

Mechanical function test

The actuator must slide easily into the actuating

head. Close the safety guard several times to check

the function.

Electrical function test

1. Switch on operating voltage.

2. Close all safety guards.

The machine must not start automatically.

3. Enable operation in the control system.

4. Open the safety guard.

The machine must switch off and it must not be

possible to start it as long as the safety guard

is open.

Repeat steps 2 - 4 for each safety guard.

Inspection and Service

If damage or wear is found, the complete switch

and actuator assembly must be replaced.

Replacement of individual parts or assemblies

is not permitted!

No servicing is required, but regular inspection

of the following is necessary to ensure trouble-free

long-term operation:

correct switching function

secure mounting of components

dirt and wear

sealing of cable entry

loose cable connections or plug connectors.

Note:The year of manufacture can be seen in the

bottom, right corner of the rating plate.

Exclusion of Liability under the Following

Conditions:

incorrect use

non-compliance with safety regulations

installation and electrical connection not per-

formed by authorized personnel

failure to perform functional checks.

A