Enerpac LU7-Series User Manual

Page 5

5

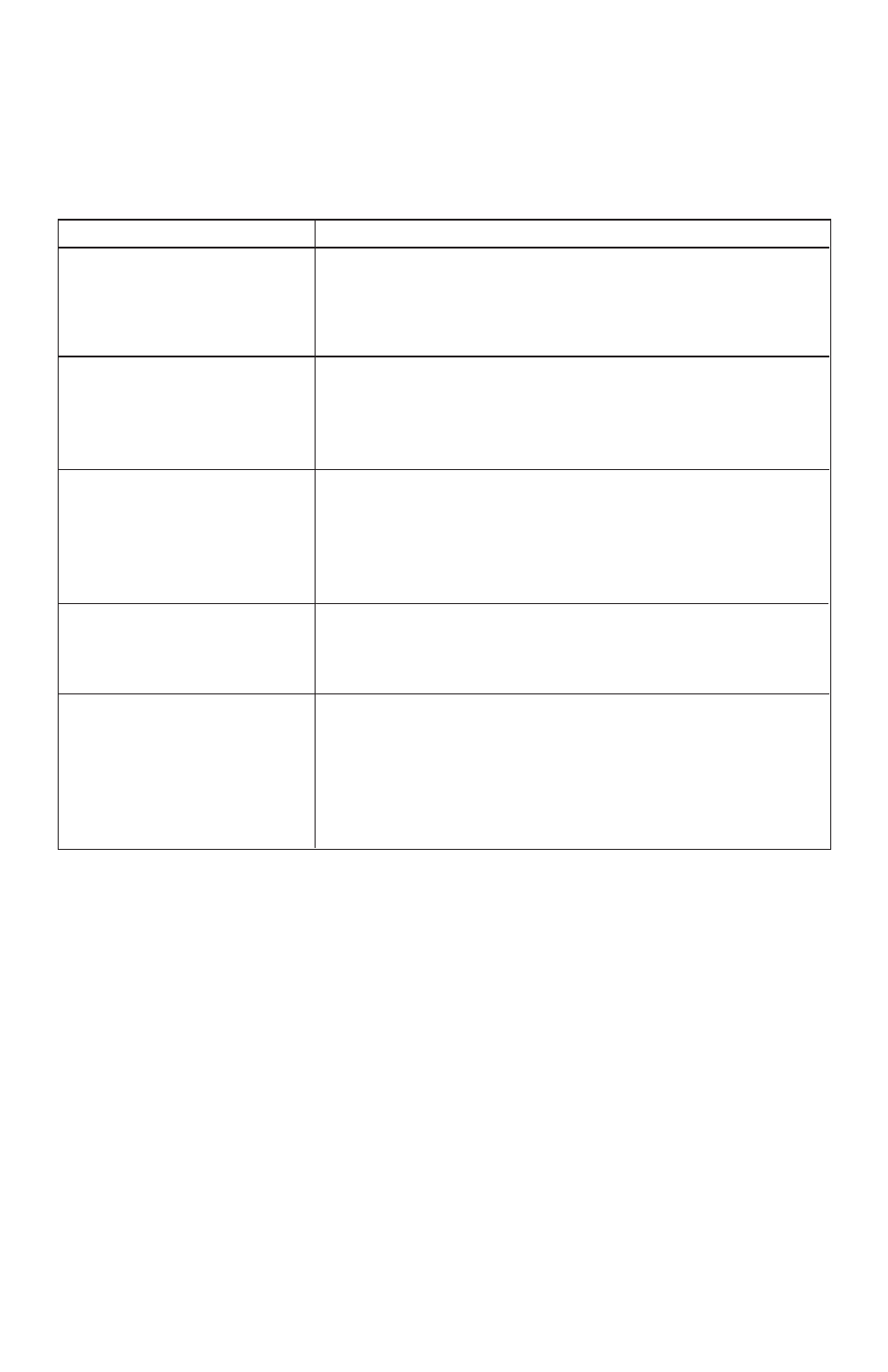

PROBLEM

POSSIBLE

CAUSE/SOLUTION

Control valve not open or damaged.

Couplers or fittings not properly connected.

Pump is not developing flow or pressure.

Linkage is not attached properly.

Linkage is bound by either misalignment or built up contamination.

Control valve not open or damaged.

Couplers or fittings not properly connected.

Pump is malfunctioning.

Linkage is bound by either misalignment or built up contamination.

Air in hydraulic system.

Control valve damaged.

Couplers or fittings leaking.

Pump is malfunctioning.

Internal seals are damaged and need replacement.

Cylinder bore or plunger are damaged and need replacement.

Clamp arm is not properly contacting part. Adjust contact bolt.

Internal seals are damaged and need replacement.

Cylinder bore or plunger are damaged and need replacement.

If cylinder is manifold mounted, O-rings could be damaged or

pinched and need replacement.

Control valve not open or damaged.

Couplers or fittings not properly connected.

Pump is malfunctioning.

Linkage is bound by either misalignment or built up contamination.

Air in hydraulic system.

Restrictions in return line. Check all installed accessories such as

filters for proper operation.

Cylinder plunger will not

advance.

Cylinder advances in spurts.

Cylinder advances but does not

hold pressure or provide clamp

force.

Cylinder leaks oil.

Cylinder will not retract or

retracts slowly.

6.0 TROUBLESHOOTING GUIDE

Allow only qualified hydraulic technicians to service the link clamp or system components. A system failure

may or may not be the result of a link clamp malfunction. To determine the cause of the problem, the complete

system must be included in any diagnostic procedure.

The information in the following chart is intended to be used only as an aid in determining if a problem exists.

For repair service, contact your local Authorized Enerpac Service Center.