Enerpac LU7-Series User Manual

Page 3

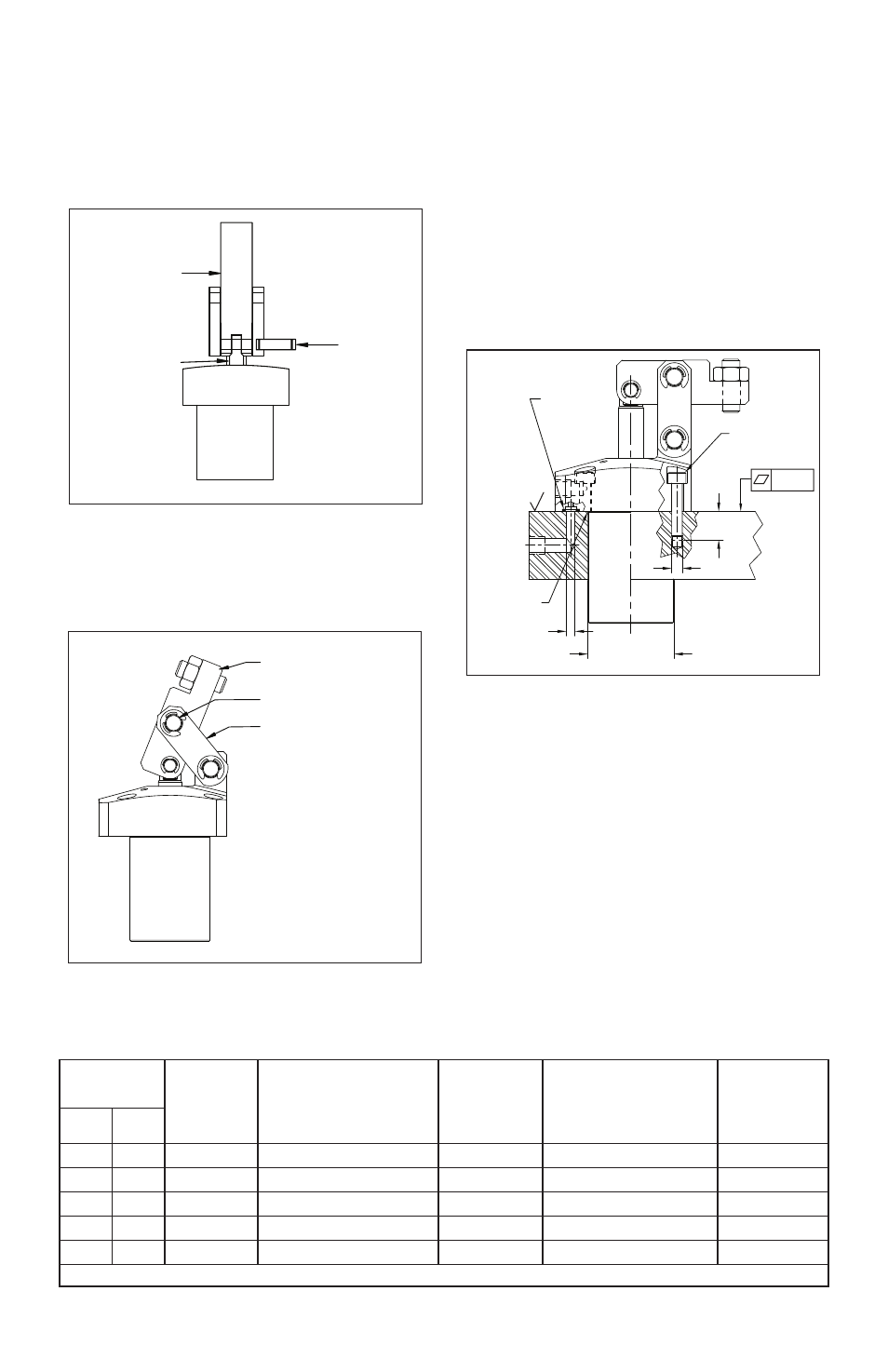

3.2 Arm Attachment

Place the clamp arm over the plunger end, lining up

the pivot pin holes. The clamp arm should extend

between the two links previously installed. Insert

the supplied short pivot pin through the arm and the

plunger, securing the parts together with the supplied

E-clips (See Figure 4).

Clamp Arm

Plunger

Figure 4

Then, insert the second long pivot pin through the

top holes on the links and through the top hole on

the clamp arm, securing it with the last two supplied

E-clips (See Figure 5).

Clamp Arm

Pivot Pin (long)

Link

Figure 5

3.3 Cylinder Mounting

The Enerpac 70 bar link clamp features a 4 bolt

flange style body for mounting the cylinder to the

fixture plate. Mounting bolts of the proper size and

length are supplied. Flange mounting requires the

machining of a through hole in the fixture plate or

mounting block and threads for the four (4) mounting

bolts. (See Figure 6 and Table 1).

Align the cylinder in the proper orientation to provide

clamping force to the part. Then, install the mounting

bolts and tighten per the value shown in Table 1.

Failure to properly tighten the mounting bolts can

result in damage to the cylinder and premature failure

of the clamp.

øD3

J

63

ø 4,8

Mounting Bolts

(included)

Manifold

O-Rings

(included)

Mtg. Hole

J2

0.004

.5mm x 45°

Figure 6

3.4 Oil Connections

The cylinder can be plumbed using either the

hydraulic ports on the side of the flange, or the

manifold O-ring ports on the underside of the flange.

When using the manifold O-ring ports, use a 4.8 mm

diameter feed passage. The feed passage should

align with the center of the O-ring.

Hydraulic Fittings

The Enerpac 70 bar link clamp is supplied with BSPP

ports in the side of the flange. Connect the oil supply

to these ports using fittings rated for a minimum of

70 bar [1000 psi] only. Single acting (spring return)

models are vented. The supplied vent fitting may be

removed if using the manifold port for the vented

port.

3

Table 1 - Specifications

Clamp

Force

1)

Mounting

Hole

Ø D3

mm

Mounting Bolt

Thread

J

Min. Depth

J2

mm

Manifold O-ring

2)

ARP No.

Lubricated

Bolt Torque

Nm

kN

lbs.

2

450

36.5

M5 x .08 x 30 mm long

12

568-010

8.0-9.0

3.5

787

42.5

M5 x .08 x 30 mm long

12

568-010

8.0-9.0

5

1124

48.5

M6 x 1.0 x 30 mm long

16

568-011

13.5-15.0

7

1574

54.5

M6 x 1.0 x 30 mm long

16

568-011

13.5-15.0

9

2023

60.5

M8 x 1.25 x 30 mm long

18

568-011

32.0-38.0

1)

At rated clamp point.

2)

O-rings and mounting bolts are included.

Pivot Pin

(short)