Enerpac ST-52 User Manual

Page 8

7.0 OPERATION

Swing cylinders rotate 90° during the first portion of the stroke, continuing without rotation for the final

clamping stroke. The straight downward stroke is the clamping stroke of the cylinder. Clamping force must be

applied only during the vertical travel, not during the swing motion.

CAUTION:

— If clamping force is applied during the rotation portion of the stroke, internal plunger damage will result.

— To ensure maximum cylinder performance and safety; be sure all hydraulic connections, hoses, and

fittings are properly sealed and fully tightened.

— Be sure all items are rated to withstand system pressures. Under-rated components will not withstand

higher pressure. Using under-rated components will lead to equipment damage and possible personal

injury.

7.1 Vent Plug

Single-acting cylinders have a vented plug on the left side of the cylinder when you are facing the hydraulic

ports. To prevent entry of chips and coolant, the vent plug must not be removed. If the vent plug is subjected

to a continuous coolant flood condition, attach tubing to the port using a BSPP fitting, and run the tubing to a

non-contaminated area of the fixture.

7.2 Pressure and Flow Rate

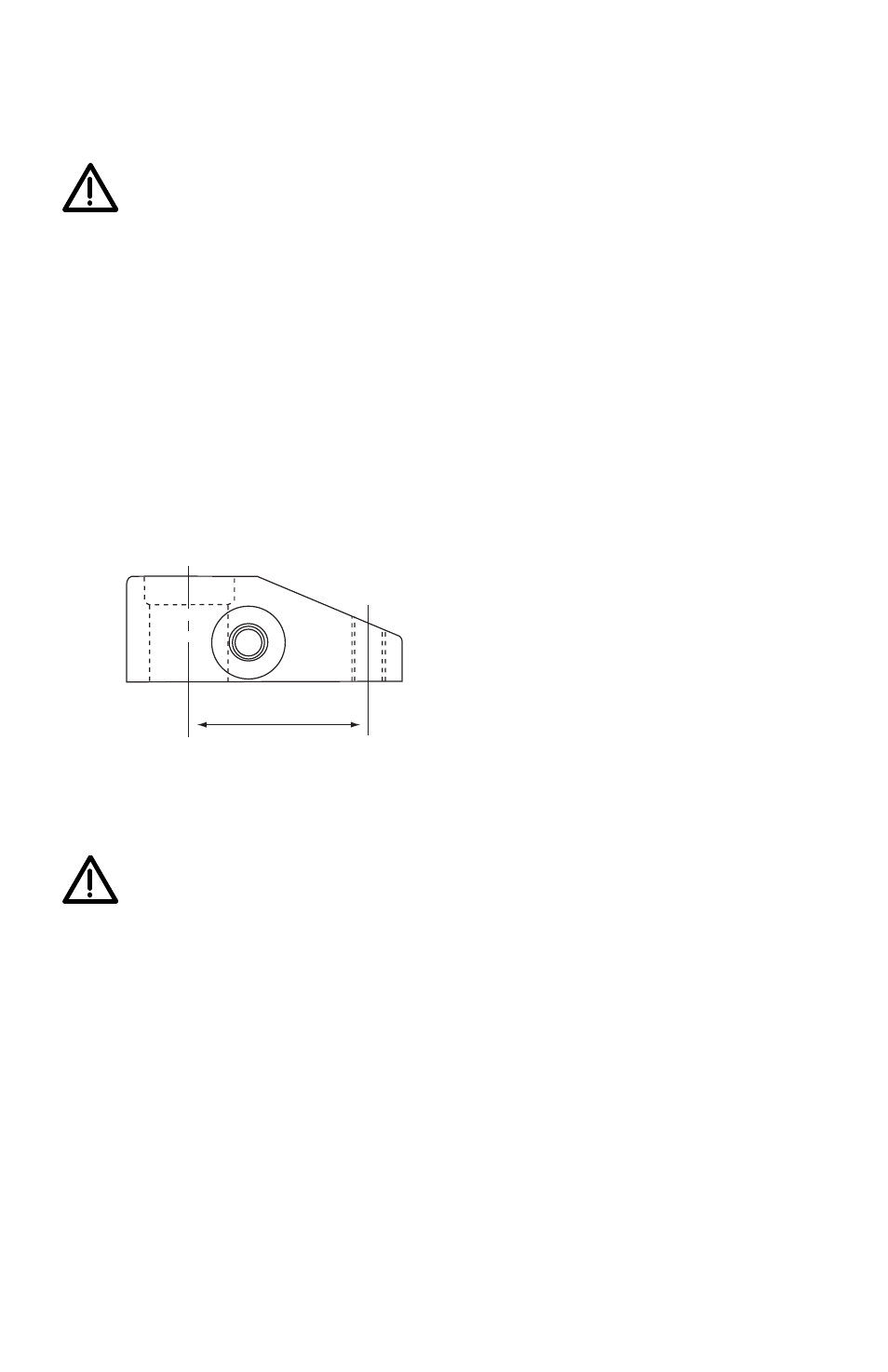

Clamp arm length (L) determines operating pressure setting and flow rate.

See Operating Specifications — Maximum Flow Rate Chart on page 2 for clamp arm length, pressure setting

and flow rate. Set operating pressure and flow rate according to the limits established by the length of the

clamp arm. Do not exceed the load-to-length pressure ratios. As the arm length increases, the clamping force

and maximum operating pressure are reduced.

CAUTION: It is very important that you use the correct pressure and flow settings. Operating

outside these limits will cause damage to the swing cylinder. Damage caused by exceeding

rated pressure and maximum flow is NOT COVERED BY WARRANTY.

8.0 MAINTENANCE

Maintenance is required when wear or leakage is noticed. Occasionally inspect all components to detect any

problem requiring service and maintenance. Enerpac offers ready-to-use Repair Parts Kits. Repair Parts Sheets

are available with assembly drawing and parts list. Contact Enerpac.

IMPORTANT: Consult the Repair Parts Sheet for service information about correct assembly and disassembly.

Incorrect maintenance and service such as wrong torque values may cause product malfunctions and/or

personal injury.

9.0 TROUBLESHOOTING

The following information is intended to be used only as an aid in determining if a problem exists. For repair

service, contact your Distributor or Authorized Enerpac Service Center.

L

8