Attaching clamp arm, Arms for upper flange body style – Enerpac ST-121 User Manual

Page 7

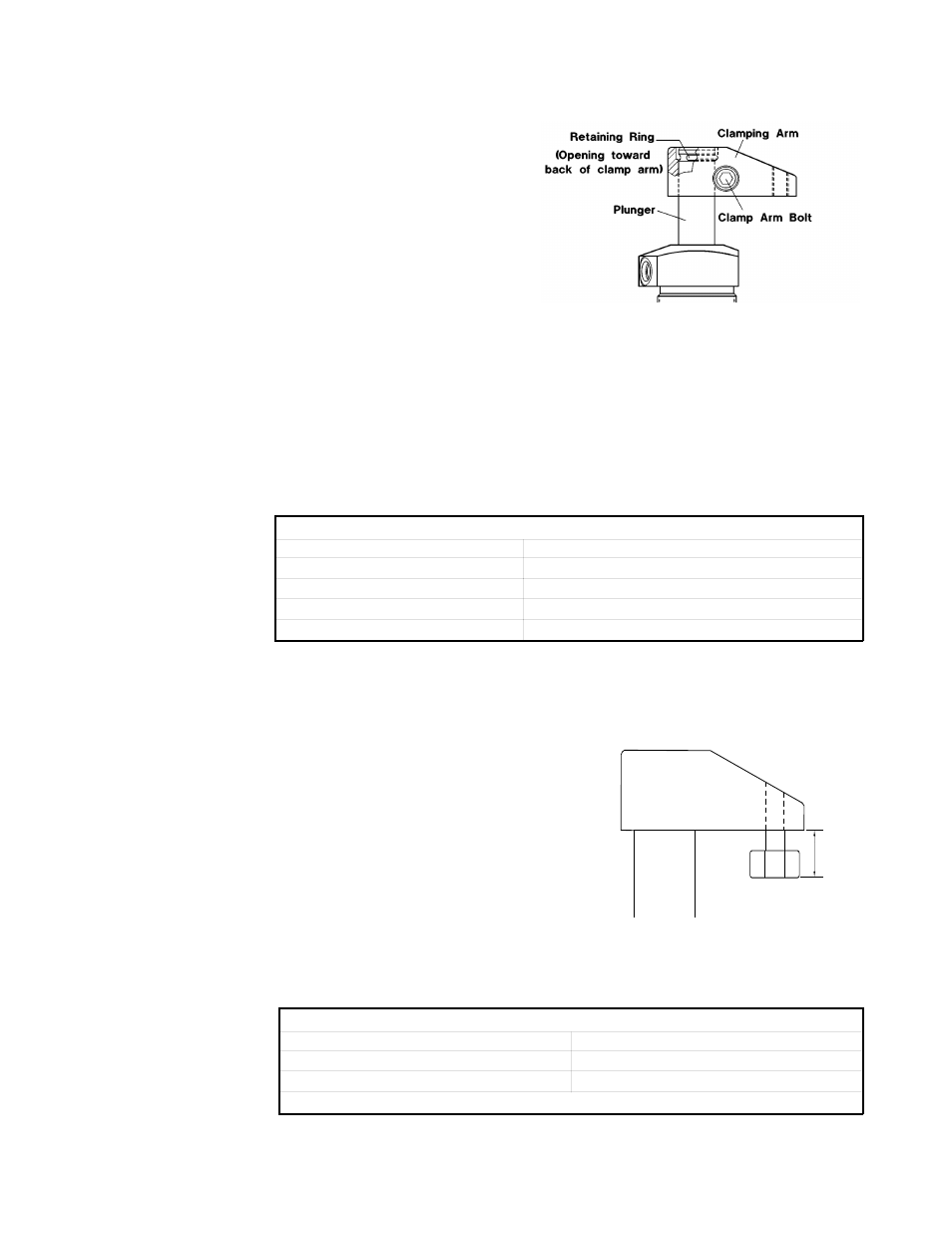

Attaching Clamp Arm

1. Remove the retaining ring from the top of the plunger.

2. Slide the clamp arm down

over the plunger and use a

pliers to push the retaining

ring back onto the plunger

groove. Orient the

retaining ring so the

retaining ring gap will face

the back of the clamp arm.

See illustration.

3. Move the clamp arm up until it is firmly against the retaining ring and in the

desired position. While maintaining this position, torque the clamp arm bolt to

specification listed below.

A

CAUTION

Inadequate torquing of the clamp arm bolt could cause the arm to slip

during operation. BE SURE TO USE QUALITY GRADE 8 (8.8 DIN 912)

SOCKET HEAD CAP SCREWS (supplied with standard clamp arms).

Arms for Upper Flange Body Style

To use the upper flange body style cylinders,

you have to be sure that the contact bolt will

clear the upper flange during operation. The

clamp arm must be long enough for the contact

bolt to clear the upper flange as the arm swings

down. Clearance problems are most common

when the final clamping position is at the side of

the cylinder and the contact bolt must pass by

the front or back of the upper flange as it swings

down. You may need to use the longer, CAL

Series clamp arm for these applications.

Clamp Arm Bolt Torque

Cylinder Capacity

Lubricated Torque

300 lbs (1,3 kN)

53-64 in-lbs (6,0-7,2 Nm)

500 lbs (2,2 kN)

12 to 15 ft-lbs (16,3 to 20,3 Nm)

1250 lbs (5,6 kN)

24 to 29 ft-lbs (32,5 to 39,3 Nm)

2600 lbs (11,6 kN)

44-53 ft-lbs (59,7-71,8 Nm)

Max.

Length

Contact

Bolt

Maximum Contact Bolt Length

Cylinder Capacity

Maximum Length

300 lbs (1,3 kN)

0.55" (14,0 mm)

500 lbs (2,2 kN)

0.75" (19,1 mm)

NOTE: Maximum lengths provided here are for 300 and 500 lb. upper flange models only.

7