Maintenance, Troubleshooting – Enerpac ST-121 User Manual

Page 10

MAINTENANCE

Maintenance is required when wear or leakage is noticed. Occasionally inspect all

components to detect any problem requiring service and maintenance. Enerpac

offers ready-to-use Repair Parts Kits. Repair Parts Sheets are available with

assembly drawing and parts list. Contact Enerpac.

IMPORTANT: Consult the Repair Parts Sheet for service information as to correct

assembling and disassembling. Incorrect maintenance and service such as wrong

torque values may cause product malfunctions and/or personal injury.

TROUBLESHOOTING

The following information is intended to be used only as an aid in determining if a

problem exists. For repair service, contact your Distributor or Authorized Enerpac

Service Center.

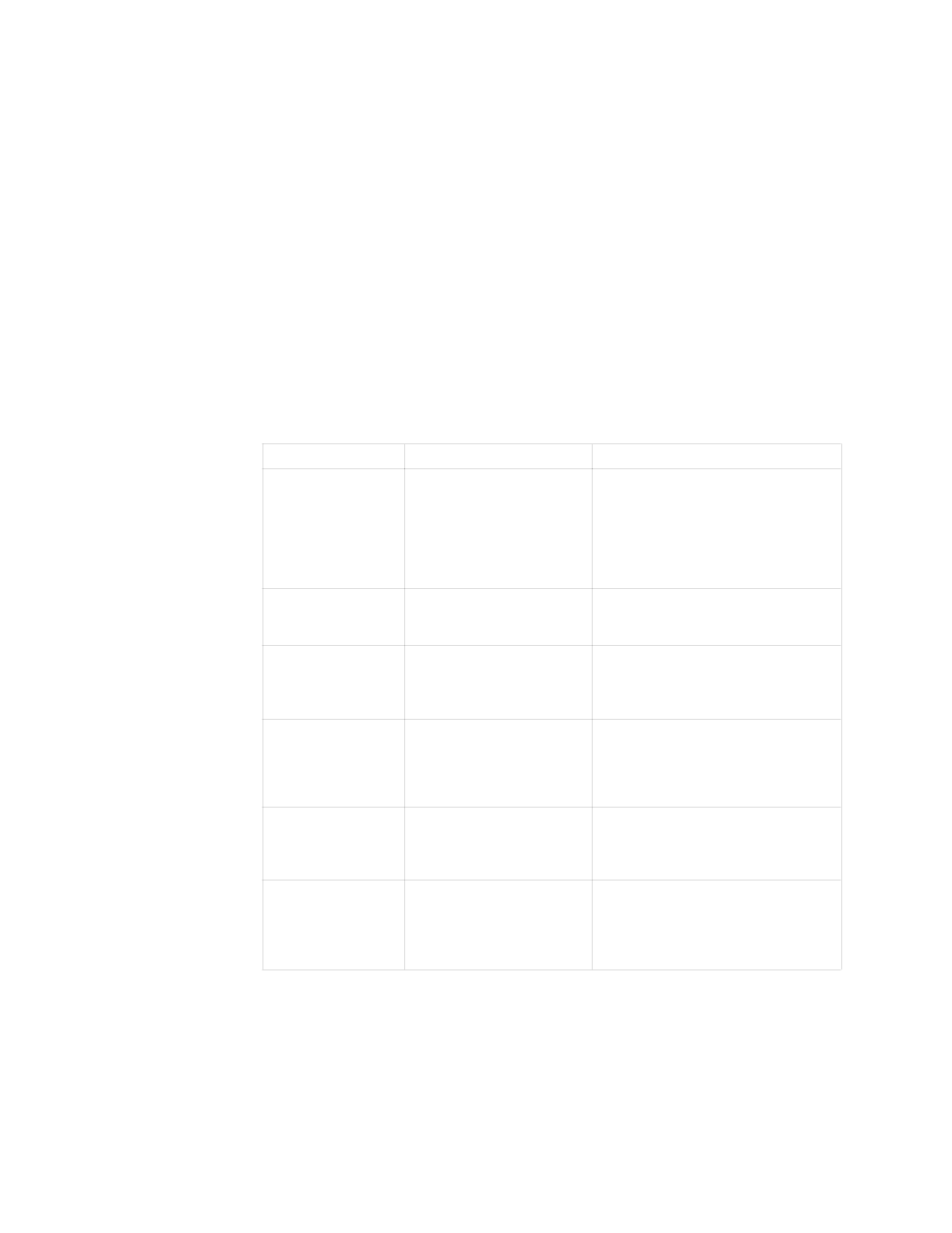

Problem

Possible Cause

Solution

1. Cylinder will not

clamp/unclamp.

A. pump release valve open

B. no oil in pump reservoir

C. air in system

D. couplers not fully

tightened

E. blocked hydraulic line

F. spring broken in cylinder

A. close pump release valve

B. fill pump reservoir

C. remove air from hydraulic system

D. retighten couplers

E. check valves, fittings, and tubing

F. replace spring

2. Cylinder advances

part way.

A. oil level in pump too low

B. plunger binding

A. fill pump reservoir

B. replace damaged parts

—refer to Repair Parts Sheet

3. Cylinder

clamps/unclamps

slower than normal.

A. leaking connection

B. restricted hydraulic line

C. pump malfunction

A. retighten fittings, couplers,

and tubing

B. check valves, fittings, and tubing

C. refer to pump Instruction Sheet

4. Cylinder

clamps/unclamps

but will not hold

pressure.

A. seals damaged

B. leaking connection

C. pump malfunction

A. replace seals

—refer to Repair Parts Sheet

B. retighten fittings, couplers,

and tubing

C. refer to pump Instruction Sheet

5. Cylinder leaks oil. A. seals damaged

B. plunger worn or damaged

A. replace seals

—refer to Repair Parts Sheet

B. replace damaged parts

—refer to Repair Parts Sheet

6. Clamp arm does

not make swing

movement.

A. clamp arm loose

B. plunger damaged

A. reposition and tighten clamp arm

—see Attaching Clamp Arm

on page 7

B. replace damaged parts

—refer to Repair Parts Sheet

10