Enerpac WST-72 User Manual

Page 7

MAINTENANCE AND SERVICE

Maintenance is required when wear and/or leakage is noticed. Occasionally inspect all

components to detect any problem requiring service and maintenance. Enerpac offers

Repair Part Kits for equipment maintenance. Repair Part Sheets are also available.

Contact your Enerpac representative.

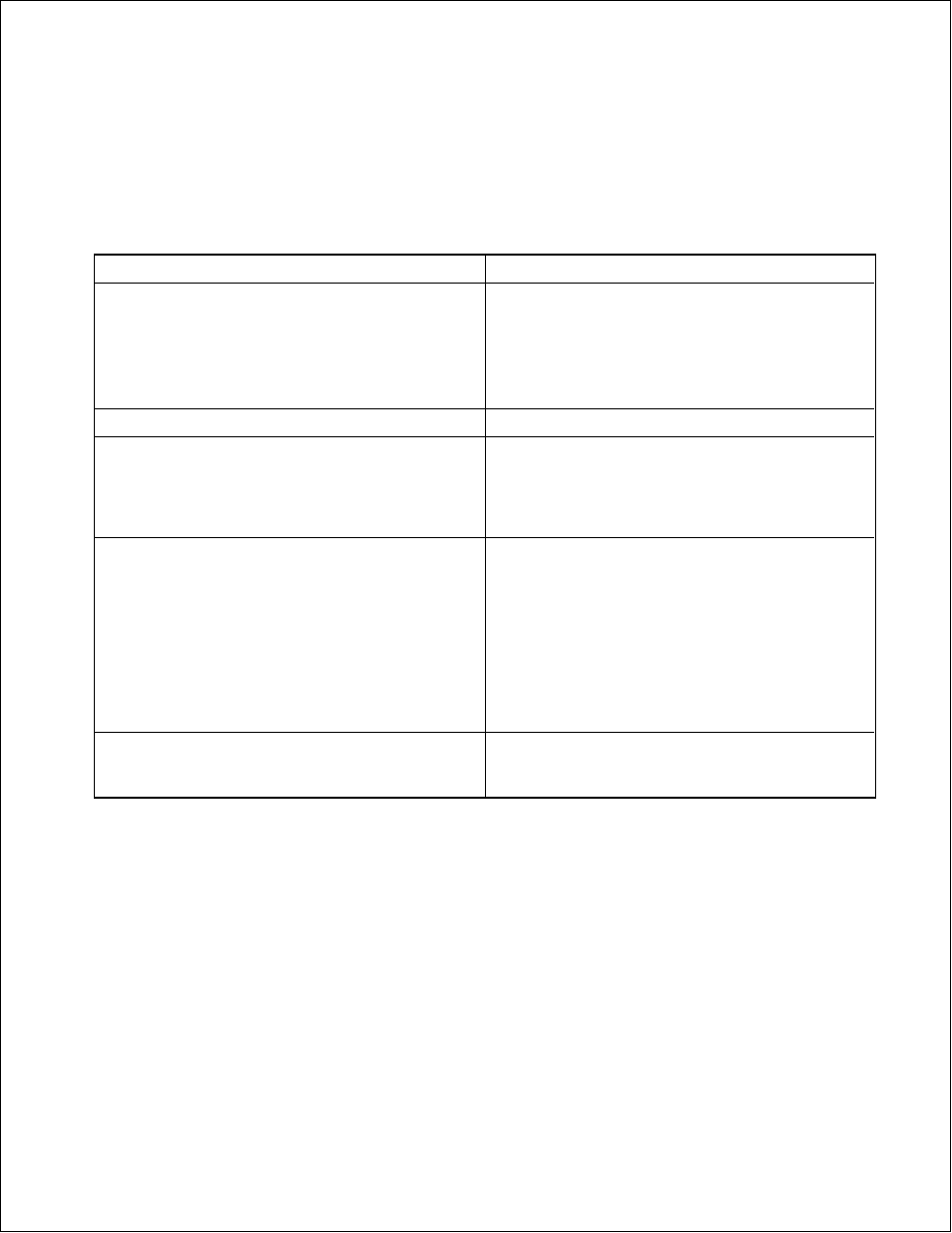

TROUBLESHOOTING

Problem

Possible Cause

Plunger will not advance completely when system

pressure is activated.

Determine if hydraulic system is exceeding maximum

flow rate (see specifications table).

Check for broken take up spring.

Check plunger and sleeve for damage.

Work support raises part off of rest surfaces.

Work support may be over–size for application.

Work Support plunger is slipping.

Hydraulic pressure may be below minimum amount to

hold plunger.

Cutting forces may be exceeding the capacity of the

work support.

Plunger will not retract.

Plunger will not release to extended height.

Hydraulic pressure has not been released from the

system.

Excessive back pressure from small diameter tubing or

tight bends.

Check plunger, sleeve, and wiper for damage or debris

accumulation.

Check for broken return spring.

Work support leaks oil.

Check seals for wear or damage.

Connection to work supports may be leaking.

7