Enerpac LCA-Series User Manual

Page 4

plate is designed to withstand full clamping capacity.

A jam nut is still required in this case to maintain the

clamping orientation. The jam nut should be installed

on the inside of the fixture plate for most secure

mounting.

3.4 Oil Connection

The cylinder can be plumbed using either the

hydraulic ports on the side of the flange, or the

manifold O-ring ports on the underside of the flange.

The manifold ports can only be used when the

cylinder is flange mounted using the four mounting

bolts as shown in Figure 6.

Hydraulic Fittings

Enerpac link clamps are supplied with either SAE O-

ring ports or BSPP ports in the side of the flange.

Single acting cylinders require only one hydraulic

port. Unlike many other cylinders, single acting

Enerpac link clamps do not require the use of a vent

port. Connect the oil supply to this port using fittings

rated for a minimum of 5000 psi (350 bar) only.

Double-acting cylinders require two ports to operate.

The port marked “A” should be connected to the

clamp line of the circuit. The port marked “B” should

be connected to the unclamp side of the circuit.

Again, be sure to use fittings and tubing rated for a

minimum of 5000 psi (350 bar) working pressure.

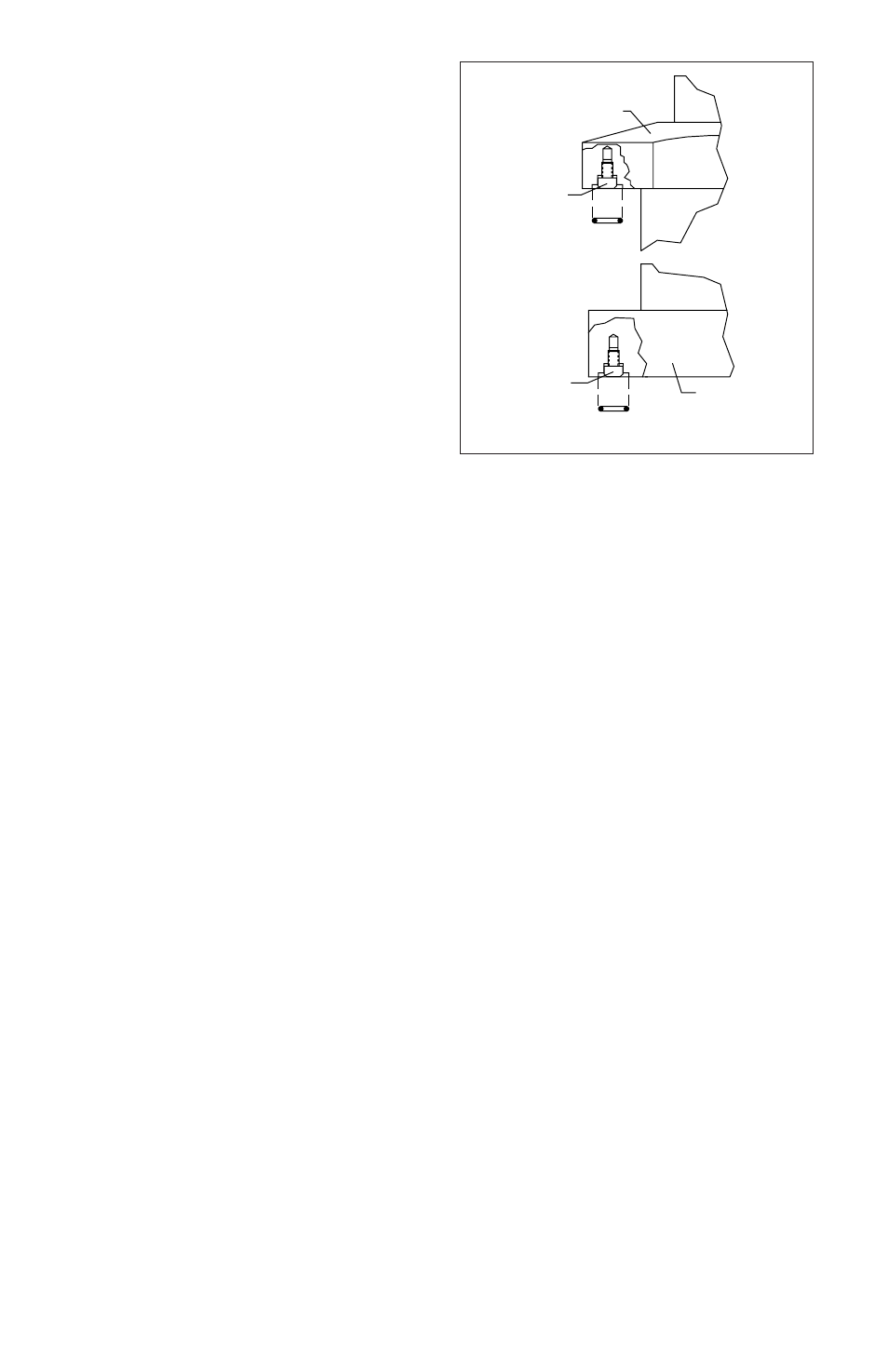

Manifold ports

Enerpac link clamps can also be plumbed using the

manifold ports on the underside of the flange. The

clamps are supplied from the factory with small cap

screw and copper gasket installed in these ports

(Figure 7). Remove these items before installation.

The manifold ports require the use of O-rings as face

seals between the cylinder flange and the fixture

plate. These O-rings are supplied with the clamp,

typically in a small plastic bag along with the

mounting bolts and the documentation. Install these

O-rings (only one O-ring required for single acting

cylinders) into the seal grooves on the underside of

the mounting flange (Figure 7).

Before installation, the O-rings should be coated with

a small amount of hydraulic oil to prevent damage

during operation. Mount the clamps using the

installation instructions in section 3.3. Remember

that the cylinders must be flange mounted when

using the manifold porting method.

Figure 7

4.0 OPERATION

Enerpac link clamps operate on hydraulic pressure

from 500 to 5000 psi (35-350 bar). This oil pressure is

supplied via an external pump plumbed through a

circuit of valves to the link clamps and other clamping

elements on the fixture. Single acting cylinders only

require one hydraulic line to provide clamping force,

and use an internal spring to retract the clamp arm

when pressure is removed. Double acting cylinders

require two hydraulic lines; one line provides pressure

to advance the arm and clamp the part; the other line

provides pressure to push the arm back and unclamp

the part. Either manual, air or electrically operated

valves are used to direct oil to one port or another.

5.0 MAINTENANCE

1. Use only Enerpac oil with these cylinders. The use

of any other oil may invalidate your warranty.

2. Dynamic hydraulic seals need periodic

replacement due to normal wear and tear. A

regularly scheduled maintenance inspection plan

will help prevent unnecessary interruptions in

production due to seal wear.

3. The clamp linkage can be damaged or broken due

to mis-loaded parts or excessive contamination

build up. Any clips or pins that appear damaged

or worn should be replaced immediately.

4. All maintenance should be done by a qualified

hydraulic service technician. Enerpac has a global

service center network that can provide repair and

maintenance services if needed.

4

Remove port

screw plug.

Lower flange

Upper flange

O-ring

O-ring

Remove port

screw plug.