Enerpac LCA-Series User Manual

Page 2

2

IMPORTANT:

Do not lift hydraulic

equipment by the hoses or swivel

couplers. Use the carrying handle or other

means of safe transport.

CAUTION: Keep hydraulic equipment

away from flames and heat. Excessive

heat will soften packings and seals,

resulting in fluid leaks. Heat also weakens

hose materials and packings. For optimum

performance do not expose equipment to

temperatures of 65 °C [150 °F] or higher. Protect

hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized

hoses. Escaping oil under pressure can

penetrate the skin, causing serious injury.

If oil is injected under the skin, see a doctor

immediately.

WARNING: Only use hydraulic cylinders in

a coupled system. Never use a cylinder

with unconnected couplers. If the cylinder

becomes extremely overloaded, components

can fail catastrophically causing severe personal injury.

IMPORTANT: Hydraulic equipment must

only be serviced by a qualified hydraulic

technician. For repair service, contact the

Authorized ENERPAC Service Center in

your area. To protect your warranty, use only

ENERPAC oil.

WARNING: Immediately replace worn or

damaged parts by genuine ENERPAC parts.

Standard grade parts will break causing

personal injury and property damage. ENERPAC parts

are designed to fit properly and withstand high loads.

3.0 INSTALLATION

The Enerpac link clamp can be installed with the

clamp arm in one of three different locations. The

clamps can be mounted to the fixture using either the

threaded body or the supplied mounting bolts. Oil

can be supplied to the clamp using either the

threaded hydraulic ports on the flange or via the O-

ring ports on the underside of the flange. The

sections that follow provide detailed mounting

instructions and should be reviewed before

attempting to install the clamps on the fixture.

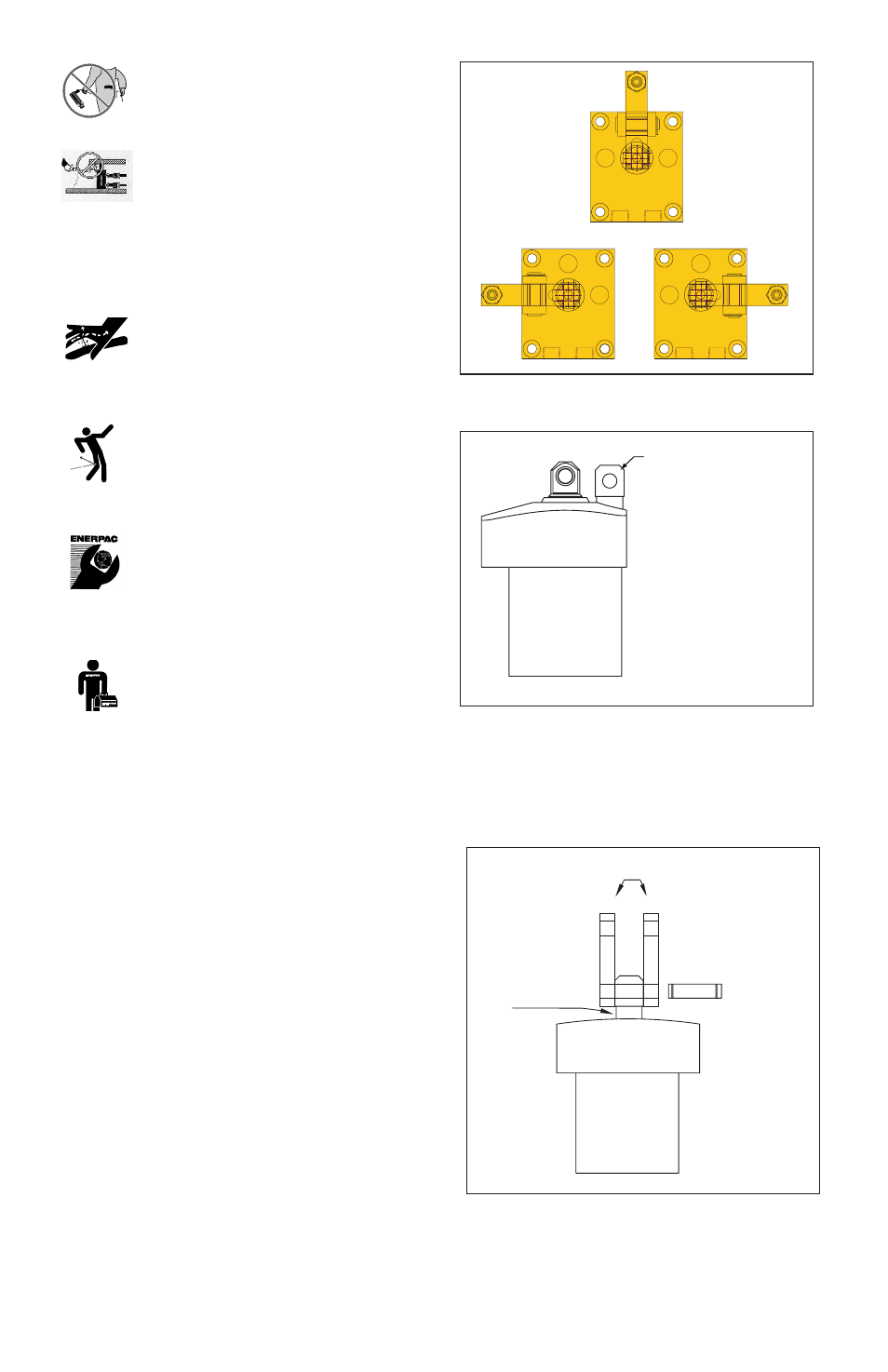

3.1 Clamp Arm Location

The arm and linkage can be positioned in any of three

different positions as shown in Figure 1 below. The

anchor post threads into the top flange of the cylinder

in any of the three threaded holes. Thread the anchor

post into the flange until it bottoms out, then turn the

post back up to 1/2 turn in order to line up the pivot

pin hole perpendicular to the desired clamp direction

(Figure 2). Make sure that the hole in the plunger is

lined up parallel to the hole in the anchor post.

Figure 1

Figure 2

Line up the two (2) links with the hole in the anchor

post. Insert one (1) of the long pivot pins through the

links and the anchor post. Secure the pivot pin in

place using two (2) of the supplied E-clips (Figure 3).

Figure 3

Center

Hole in anchor post

must line up

perpendicular to

direction of clamp

arm.

Anchor post

Pivot pin

Links

Left

Right