Enerpac LCA-Series User Manual

Page 3

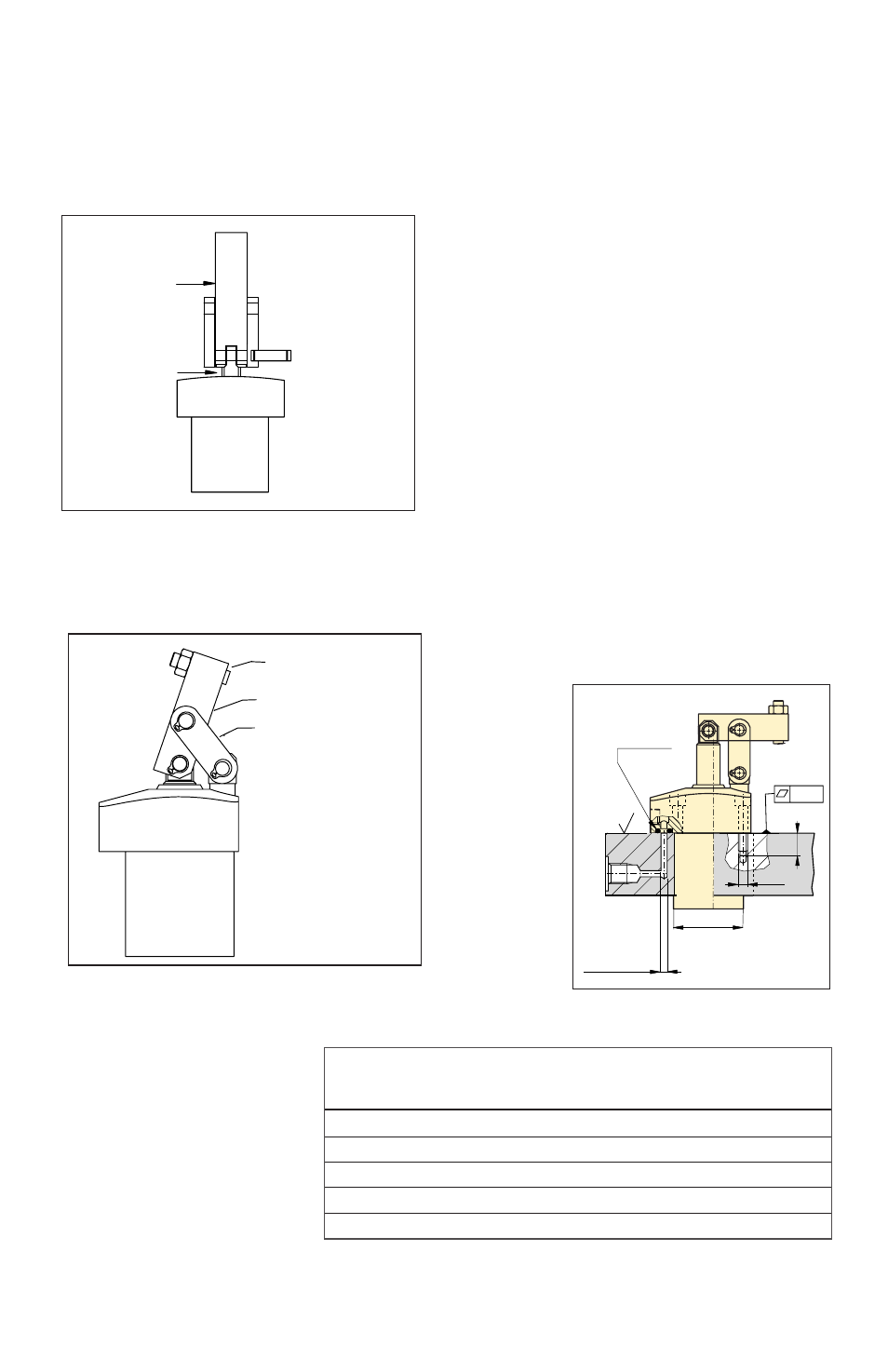

3.2 Arm Attachment

Place the clamp arm over the plunger end, lining up

the pivot pin holes. The clamp arm should extend

between the two links previously installed. Insert the

supplied short pivot pin through the arm and the

plunger, securing the parts together with the supplied

E-clips (Figure 4).

Figure 4

Then, insert the second long pivot pin through the

top holes on the links and through the top hole on the

clamp arm, securing it with the last two supplied

E-clips (Figure 5).

Figure 5

3.3 Mountings

Cylinder Mounting

Enerpac link clamps can be mounted using either the

top flange and the supplied mounting bolts; or

through the use of the body thread on the cylinder

and a jam nut.

Note: mounting the cylinders using the body threads

prevents plumbing the cylinders through the manifold

ports on the underside of the flange. The only way to

utilize this plumbing method is to flange mount the

cylinder.

Flange Mounting

Flange mounting requires the machining of a thru-

hole in the fixture plate or mounting block and

mounting threads for the four bolts (Figure 6).

See Table 1 below.

Align the cylinder in the proper orientation to provide

clamping force to the part and then install the

mounting bolts and tighten per the chart below.

Failure to tighten the mounting bolts properly can

result in damage to the cylinder and premature failure

of the clamp.

Threaded Body Mounting

Mounting the cylinder using the body threads

requires a clearance hole machined in the fixture

plate and the installation of a jam nut to secure the

cylinder in

place. The

c l e a r a n c e

hole should

be sized

according to

t

h

e

dimensions

in Figure 6.

The fixture

plate can

also be

machined to

m a t c h i n g

i n t e r n a l

threads as

long as the

3

D3

J

J2

ø .19 [4,8]

63

[1,6]

.004

0,1

Figure 6

Pull

1)

Fixture

Mounting

Min.

Manifold O-ring

2)

force

hole

thread

depth

ARP No. or

lbs

Ø D3

J

UNF

J2

Inside Ø x thickness

700

1.885

.250-28

0.65

-010

1800

2.510

.312-24

0.75

-010

2700

3.135

.312-24

0.75

-010

4300

3.515

.375-24

0.88

-010

6300

4.140

.500-20

0.94

-010

1) With standard clamp arm.

2) Polyurethane, 92 Durometer

Note: Mounting bolts and

O-rings included.

Manifold

O-ring

Table 1

Clamp arm

Clamp arm

Pivot pin

Pivot pin

Link

Plunger