Enerpac FSM-Series User Manual

Page 6

6

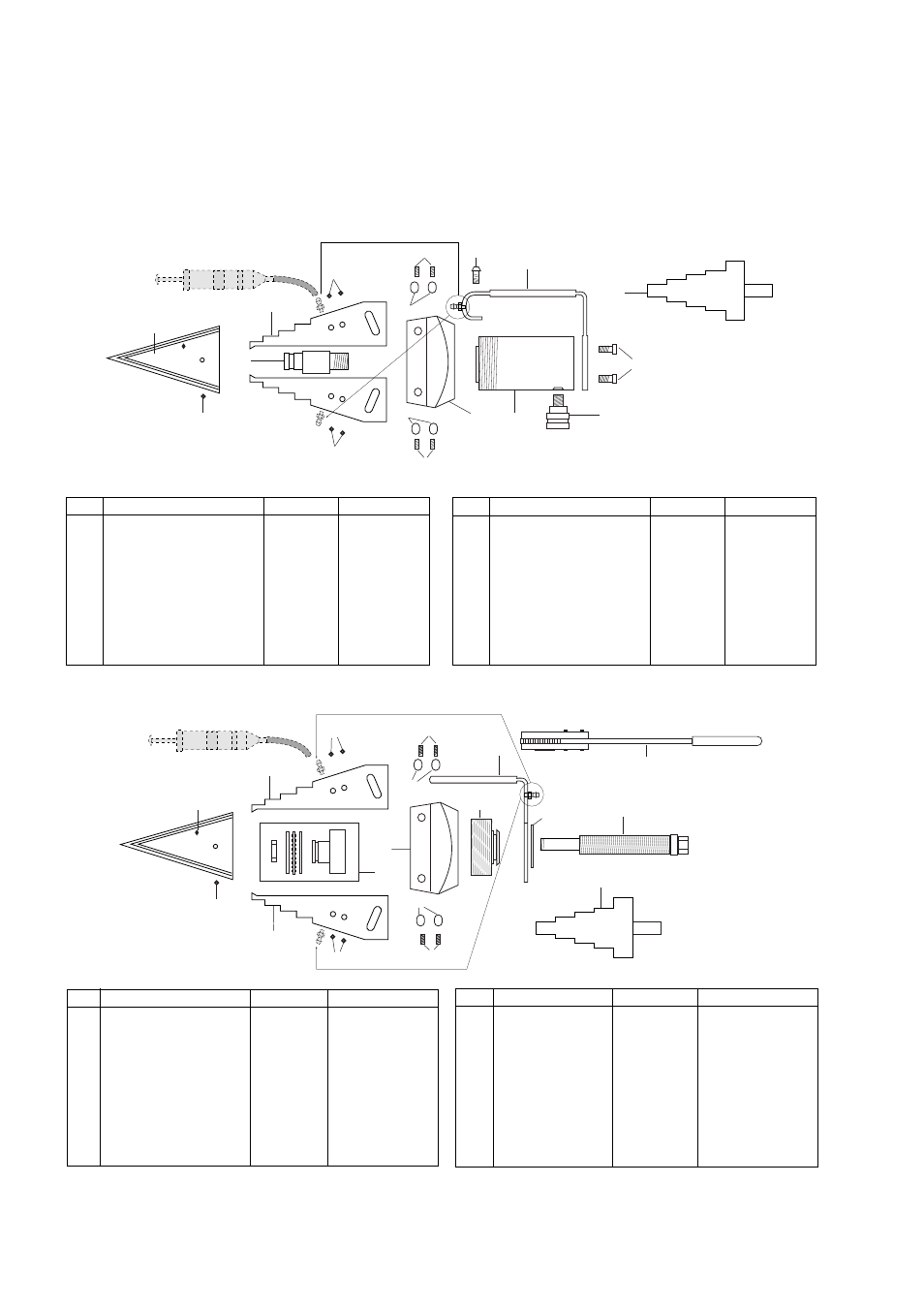

8.0 MAINTENANCE/ SERVICE

Regularly inspect all components to detect

any problem requiring service and maintenance.

To prolong the life of your Enerpac equipment, follow

points below:

• Always clean and lubricate after usage.

• Clean and grease contact surface between wedge

and jaws with high quality grease (Molykote).

• Grease the pins (No. 5)

• Keep pushrod (No. 9 of FSM-8) clean.

No. Description

Qty.

Part No.

1. Wedge

1

EN300101

2. Jaws

1 set of 2 EN300201

3. Thrust Bearing Assy.

1

EN301802SR

*4. Set Screws

1 set of 4 *

*5. Pins

1 set of 4 *

6. Male/Female

Coupling

1

EN301901

7. Handle

1

EN302001

No. Description

Qty.

Part No

1. Wedge

1

EN300101

2. Jaws

1 set of 2

EN300201

3. Connector

1

EN300301

*4. Set Screws

1 set of 4

*

*5. Pin

1 set of 4

*

*6. Handle Screw

1

*

7. Handle

1

EN300701

No. Description

Qty.

Part No.

*8. Base Screw

1 set of 2

*

9. Female Coupler

1

CR-400

10. Cylinder

1

RC-102

11. Body

1

EN301101

*12. Split Pins

1 set of 8

*

*13. Set Screws

1 set of 2

*

14. Safety Block

1

SB1**

No. Description

Qty.

Part No.

8. Circlip

1

EN302101

9. Pushrod

1

EN301802SR

11. Body

1

EN301101

*12. Split Pins

1 set of 8

*

*13. Set Screw

1 set of 2

*

14. Safety Block

1

SB1**

15. Spanner

1

SW22**

1�

�

*13

2

*12

*4

*5

11

2

*12

*4

7

6

8

9

15

14

*5

3

2

3

*4

*4

11

10

9

*8

14

7

*5

*5

*6

1

*12

*12

*13

10.0 PART LIST FSM-8

9.0 PART LIST FSH-14

Note: Items marked * supplied in Repair Kit

FS-148K

** Accessory Item

Note: Items marked * supplied in Repair Kit

FS-148K

** Accessory Item