Det-Tronics C7050 A, C, G, P UV Flame Detector User Manual

Page 8

resistance is 16.14 ohm/1000 ft. or 53.0 ohm/km.) The

R7404 Controller will accommodate up to 16 detectors.

The detectors can be located up to 2000 feet (600

meters) from the controller. Shielded cable is required for

the “B” (signal) leadwires. As with any field device,

shielded cable on all wires provides maximum protection

from RFI/EMI sources.

SHIPPING WEIGHT (Approximate)—

Pounds

Kilograms

Controller

2.5

1.12

Detector (aluminum)

1.25

0.56

(stainless steel or brass)

2.25

1.0

DIMENSIONS—

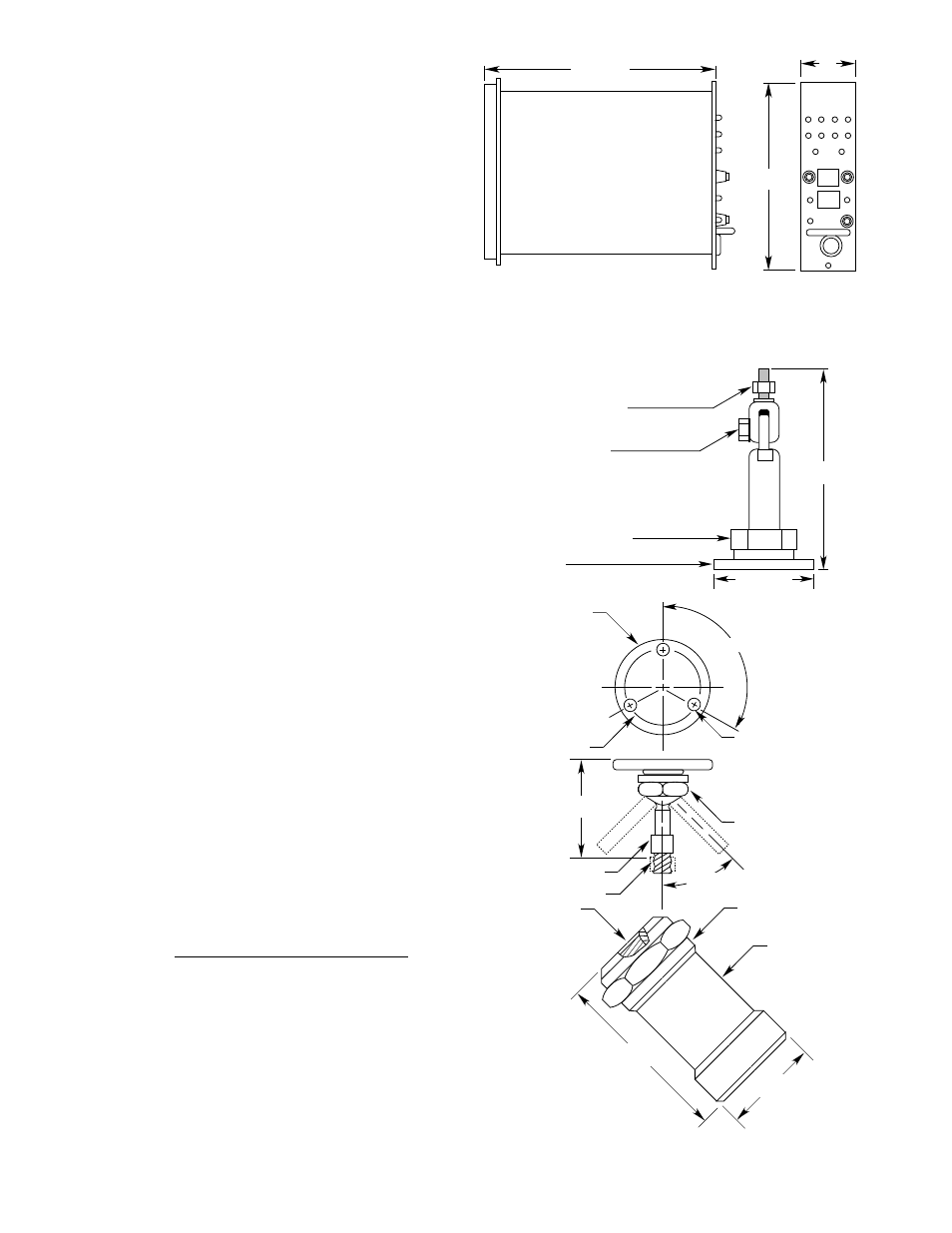

Refer to Figure 3 for dimensions of the controller and

Figure 4 for the detector and swivel mounting brackets.

Figure 5 shows the dimensions of the Q4004 Mounting

Cage. Cages that hold fewer devices are also available.

CONE OF VISION—

The C7050 Detector has a nominal 90 degree cone of

vision with the highest sensitivity along its central axis.

See Figure 7.

DETECTOR ENCLOSURE MATERIALS—

Models are available in anodized copper-free aluminum,

nickel-plated brass, or 316 stainless steel.

CERTIFICATIONS—

FMRC:

See Appendix A for details.

CSA:

Explosion-proof for Class I, Division 1,

Groups C and D.

Dust ignition-proof for Class II, Division 1,

Groups E, F, and G.

Enclosure Type 4 (Indoor and Outdoor

Use)

CSFM:

Explosion-proof for Class I, Division 1,

Groups B, C and D.

Dust ignition-proof for Class II, Division 1,

Groups E, F, and G.

CENELEC:

EEx d IIB+H2 T6 (T

amb

= –40°C to +77°C)

EEx d IIB+H2 T4 (T

amb

= –40°C to +125°C)

IP66

Special Conditions for Safe Use “X”:

The fused silica window is liable to be

damaged by impact. The detector should

be installed in such a manner as to pre-

vent the window from receiving mechani-

cal damage.

Russian

Performance Verified from –55°C to +75°C

Certification:

1Ex d IIB T6X (T

amb

= –40°C to +77°C)

1Ex d IIB T4/H2 X (T

amb

= –40°C to +125°C)

IP66

9.5 (242 MM)

7.0

(177 MM)

2.0

(50MM)

F234

Figure 3—Controller Dimensions in Inches (Millimeters)

6

5-1/4 INCHES

(133 MM)

2-1/2 INCHES

(64 MM)

MOUNTING BASE

1/2 INCH NUT USED TO ADJUST

ELBOW TO DESIRED ANGLE

1-3/8 INCH NUT USED TO ROTATE

SWIVEL/DETECTOR ASSEMBLY TO DESIRED POSITION

3/4 INCH NUT USED TO SECURE

DETECTOR TO SWIVEL MOUNT

B1323

Q9001H – USE FOR MOUNTING NICKEL/BRASS

AND STAINLESS STEEL C7050 DETECTORS

POSITIONING SWIVEL NUT

0.25 (6.4 MM) DIAMETER (3)

DETECTOR HOUSING

2-1/2 (64 MM) DIAMETER

TERMINAL CAP

2.00 (50.8 MM) DIAMETER

1/2 – 14 NPT

3/4 – 14 NPT

M20 x 1.5

M25 x 1.5 – 6H

Pg 16

5/16 – 18 UNC – 2A

DETECTOR LOCK NUT

CONDUIT OPTIONS:

OPTIONAL SWIVEL

MOUNTING BRACKET

(Q9001B, FOR ALUMINUM ONLY)

120

o

± 2

o

(2)

45

o

(2)

2-1/2

(64 MM)

2-1/2

(64 MM)

4-3/4

(121 MM)

G0121

Figure 4—Detector Dimensions in Inches (Millimeters)