Optical integrity ( oi), Startup procedure – Det-Tronics X3300EXE Protect-IR Multispectrum IR Flame Detector User Manual

Page 10

OPTICAL INTEGRITY (

oi)

AUTOMATIC

oi

The X3300 includes the Automatic Optical Integrity (

oi)

feature — a calibrated performance test that is

automatically performed once per minute to verify

complete detector operation capabilities. No testing

with an external test lamp is required. The detector

automatically performs the same test that a

maintenance person with a test lamp would perform —

once every minute, 60 times per hour. A successful

automatic

oi test

does not

produce an alarm condition.

The Protect•ir signals a fault condition when less than

50% of the detection range remains. This is indicated

by the Fault relay and is evident by the amber color of

the LED on the face of the detector. See the

“Troubleshooting” section for further information.

MANUAL

oi

The detector also incorporates a manual

oi feature that

provides the same test as the automatic

oi, and in

addition actuates the Alarm relay to verify output

operation. The manual

oi feature is available in all

models and can be performed at any time.

This test

requires bypass of all extinguishing devices to avoid

release resulting from a successful test.

The manual

oi test is activated by connecting the white

lead to power supply minus. This places the detector in

a special operating mode. First, the device de-latches

any latching outputs. Next, the IR emitters are activated.

If the resulting signals meet the test criteria, the Alarm

relay changes state and the indicating LED changes to

red. This condition remains until the white lead is

disconnected from dc minus. If the test criteria are not

met, no alarm is produced and no fault is generated.

See the “Troubleshooting” section for further details.

STARTUP PROCEDURE

When installation of the equipment is complete, perform

the “Fire Alarm Test” below.

Allow 20 to 30 minutes for the detector optics to reach

equilibrium. Housing will be warm to the touch.

8

24 VDC

4 TO 20 MA

PLC

–

+

875

Ω

MAX

AT 24 VDC

–

–

4 TO 20

MA

Oi

–24 VDC

+24 VDC

1

2

3

4

5

+

+

A2005

Oi TEST1

2

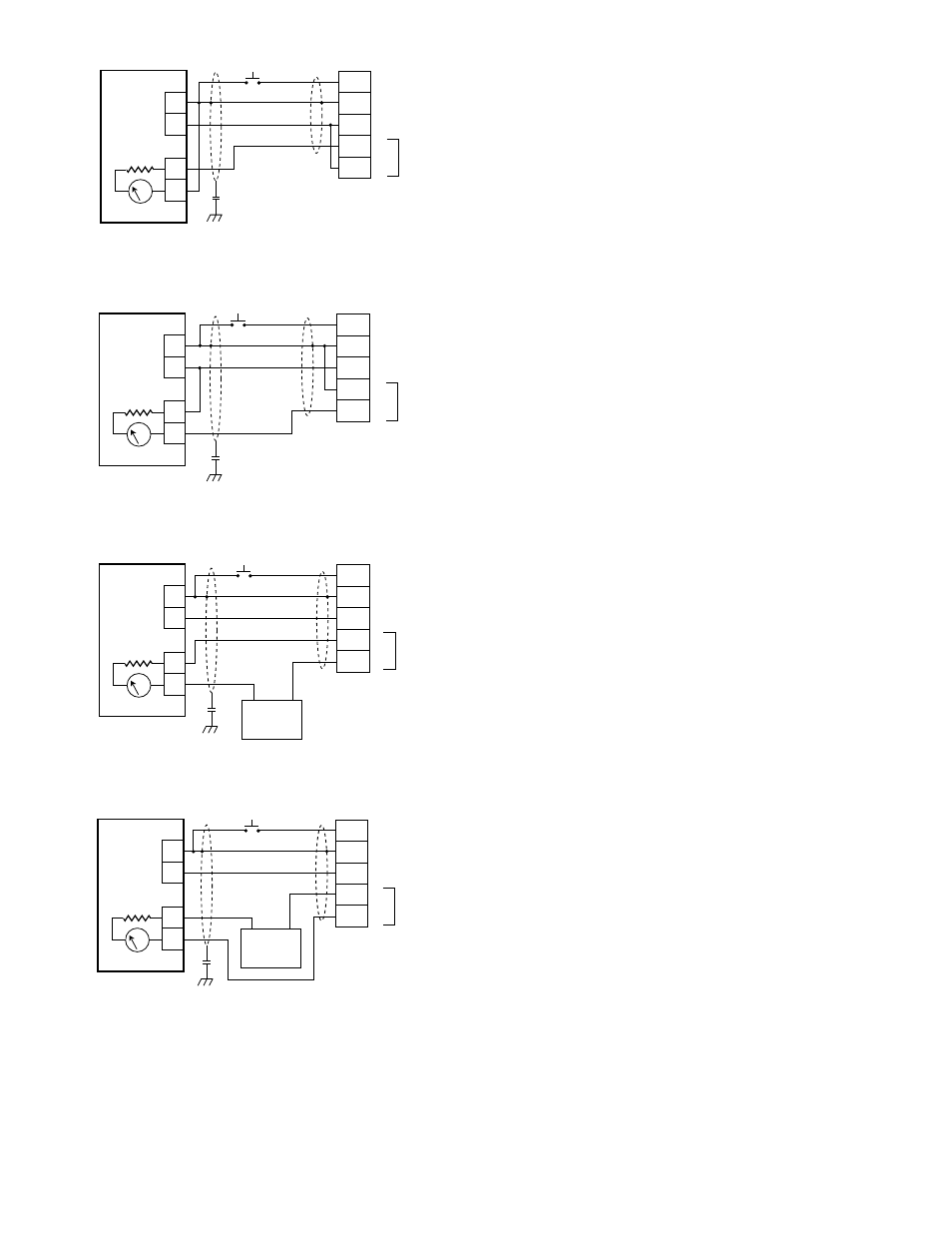

Figure 7A—X3300 Detector Wired for Non-Isolated 4 to 20 ma

Current Output (Sourcing)

24 VDC

4 TO 20 MA

PLC

–

+

875

Ω

MAX

AT 24 VDC

–

–

4 TO 20

MA

Oi

–24 VDC

+24 VDC

1

2

3

4

5

+

+

A2006

Oi TEST1

2

Figure 7B—X3300 Detector Wired for Non-Isolated 4 to 20 ma

Current Output (Sinking)

24 VDC

4 TO 20 MA

PLC

–

+

24 VDC

–

+

875

Ω

MAX

AT 24 VDC

–

–

4 TO 20

MA

Oi

–24 VDC

+24 VDC

1

2

3

4

5

+

+

A2007

Oi TEST1

2

Figure 7C—X3300 Detector Wired for Isolated 4 to 20 ma

Current Output (Sourcing)

24 VDC

4 TO 20 MA

PLC

–

+

24 VDC

–

+

875

Ω

MAX

AT 24 VDC

–

–

4 TO 20

MA

Oi

–24 VDC

+24 VDC

1

2

3

4

5

+

+

2008A

Oi TEST1

2

Figure 7D—X3300 Detector Wired for Isolated 4 to 20 ma

Current Output (Sinking)

NOTES:

1.INDIVIDUAL MANUAL oi TEST SWITCHES CAN BE

INSTALLED REMOTELY OR A DETECTOR SELECTOR AND

ACTIVATION SWITCH CAN BE INSTALLED AT THE FIRE

PANEL. TEST SWITCHES ARE NOT SUPPLIED.

2.SHIELD IS CONNECTED TO EARTH GROUND THROUGH

A 0.47µF/400V FILM CAPACITOR.