C.B.S. Scientific DGGEK-4801 User Manual

Page 6

10

11

www.cbsscientific.com

Cipher DGGE Instructions 2/28/14

2 3 4

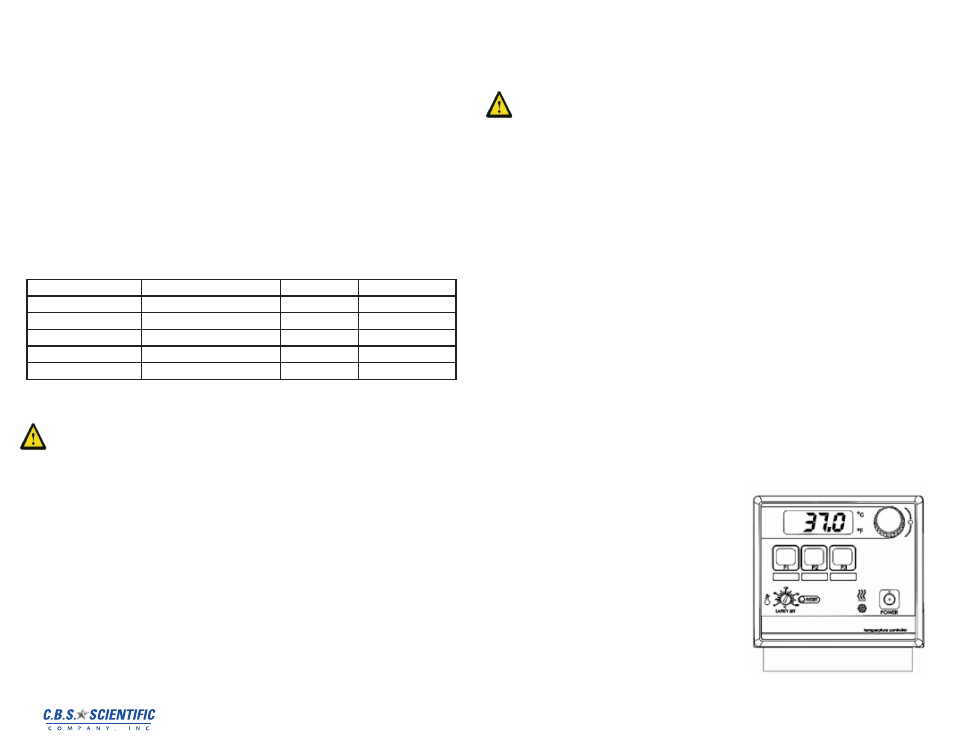

Controller Operation

2

3 4 a Reservoir Liquid Level

Fill the reservoir with the appropriate buffer. The DGGEK Systems are designed to be used

with reagent buffers such as 1xTAE or 1xTBE. On Circulating Baths, the liquid level should

be sufficient to cover the heating coils, pump, over-temperature sensor, and at least one inch

(25mm) of the temperature sensor. On Immersion Circulators, the liquid level should be suf-

ficient to fully immerse the heater coils, over-temperature sensor, and pump outlet nozzle.

2 3 4 b Power

An IEC power cord is provided with the Circulator. This power cord should be plugged into

the IEC receptacle on the rear of the Controller and then plugged into a properly grounded

outlet. Make sure that the power outlet is the same voltage and frequency indicated on the

identification label on the back of the Controller. The use of an extension cord is not recom-

mended. However, if one is necessary, it must be properly grounded and capable of handling

the total wattage of the unit. The extension cord must not cause more than a 10% drop

in voltage to the Circulator. Once the unit has been connected to an appropriate electrical

outlet, place the Circuit Breaker/Power Switch on the rear of the Controller in the ON position.

Four decimal points (….) will appear on the digital display. DO NOT place the Power Switch

on the front of the Controller ON until the Safety Set has been adjusted to the desired tem-

perature (see 3.6 below).

Indicated Voltage:

Volts/Phase/Frequency

Operational Voltage Range

Phase

Frequency

100/ 1 / 60

90 to 110 Volts

single

60 Hz

100/ 1 / 50

90 to 110 Volts

single

50 Hz

120/ 1 / 60

110 to 130 Volts

single

60 Hz

230/ 1 / 60

208 to 230 Volts

single

60 Hz

240/ 1 / 50

220 to 240 Volts

single

50 Hz

2 3 4 c Setting the Safety Set Set Point -

NOTE: DGGEK is factory set to 80ºC

The Safety Set feature automatically disconnects Controller power to the heater and pump in

the event that the reservoir liquid level drops too low or the Controller fails. The Safety Set is

user-adjustable between approximately 40° and 210°C. It should be set at least 5°C higher

than the Software High Limit temperature. Use a flat blade screwdriver to rotate the Safety

Set Indicator Knob to the desired temperature. Do not force the knob beyond the stops at ei-

ther end of the temperature value range. Once the Safety Set temperature has been set, turn

power to the Controller ON by pressing the Power Switch on the front of the Controller. The

pump will begin operating, the display will flash the current temperature set point (tx.xx), the

°C LED will light, and the current bath temperature will appear on this display. Pump speed

selection is made using the Pump Speed Selection Switch on the rear of the Controller (see

Section 2.3 or 3.3). If power is disrupted because the Safety Set temperature was exceeded,

place the Circuit Breaker/Power Switch in the OFF position, press the Safety Set Reset But-

ton, correct the problem (low liquid level, incorrect Safety Set temperature, etc.), and then

restore power. Activation of the Safety Set during normal operation will display a fault (FLt 3)

on the readout.

2 3 4 d Selecting Temperature Units

The control set point and actual bath temperatures may be displayed in either °C or °F. The

factory-default is °C. To change from °C to °F, place the Circuit Breaker/Power Switch on the

rear of the Controller in the OFF position and then press and hold the P2 Button while turning

the power back ON.

To change from °F to °C, place the Circuit Breaker/Power Switch in the OFF position and then

press and hold the P3 Button while turning the power back ON.

NOTE: When the temperature display units are changed, the Software High Limit value and all

temperature presets revert to the factory-default values. If a calibration value has been entered,

the value will be retained.

2 3 4 e Setting the Software High Limit -

NOTE: DGGEK is factory set to 75ºC

This feature provides additional safety and protection by allowing a selectable upper tem-

perature limit set point. To avoid an unwanted shutdown during regular operation, the high

limit value should be set at least 5°C higher than the selected control temperature To set the

Software High Limit temperature set point, press the P2 and P3 keys simultaneously and repeat

until (Hxxx) appears on the display. This is the current Software High Limit value. It is factory set

at 75°C. To change the displayed value, press and turn the Select/Set Knob until the desired

Software High Limit set point value is displayed. A clockwise rotation increases the value; a

counterclockwise rotation decreases the value. Press the Select/Set Knob a second time to

accept the new value and return to normal operation. If the Software High Limit value meets or

exceeds the control temperature set point, (E-H1) will flash on the display. If this occurs, enter

a higher value for the Software High Limit or reduce the control temperature set point. If the

actual bath temperature reaches the Software High Limit setpoint, (FLt1) will flash on the dis-

play. Should this occur, the Controller will automatically remove power from the heater and, in

Refrigerating/Heating units, the compressor as well. The pump will continue to operate. Once

the problem is corrected (bath temperature reduced or Software High Limit value increased),

press the Power button to clear the message.

2 3 4 f Setting the Set Point Temperature

Press and release the Select/Set Knob. The decimal point flashes to indicate that the set point

temperature can be changed. Turn the Select/Set Knob until the desired temperature set point

is displayed. A clockwise rotation increases the setting; a counterclockwise rotation decreases

the setting. Press the Select/Set Knob a second time to accept the displayed value. The deci-

mal point stops flashing and the display will indicate the actual bath temperature. Allow suf-

ficient time for the bath to stabilize at the desired temperature before making any adjustments

to set point temperature. NOTE: The unit will automatically accept the displayed set point after

approximately 10 seconds of inactivity, even if the Select/Set Knob was not pressed. The set

point temperature may be checked at any time by pressing the Select/Set Knob. If the set

point temperature cannot be raised, it is possible that the Software High Limit value is set lower

than the desired control temperature set point. Reset the Software High Limit value to 5°C or

more above the desired set point temperature.

2.3.4.g User-Definied Preset Temperatures

With the unit on, press the desired Preset Button —

P1, P2, or P3. The LED associated with the selected

Preset Button will begin to flash. Rotate the Select/

Set Knob to the desired temperature set point. Press

the selected Preset Button a second time to enter the

new set point. The new set point temperature will not

be saved unless the Preset Button is pressed. The

LED associated with Preset Button lights continu-

ously whenever that preset value is controlling bath

temperature. If more than one Preset Button is set

at a given temperature set point, the LED associated

with all Preset Buttons with that set point will light.