C.B.S. Scientific DGGEK-4801 User Manual

Page 12

22

23

www.cbsscientific.com

Cipher DGGE Instructions 2/28/14

3 5 Perpendicular Gradient Formation

To determine the range of perpendicular gradient appropriate for your fragment

analysis, please read the enclosed paper by Myers, Sheffield and Cox, as well

as the Methods and Enzymology V. 212 paper by Abrams and Stanton. This

gives you an excellent overview of the determination of melting behavior of your

fragments.

2. The following is a typical protocol for casting a 40%-60% gradient gel. Refer to

Section 3.2 Vertical Gradient Gel Casting, figure 3.5, for apparatus assembly.

In an ice bucket, place two 50ml conical tubes labeled “A” and “B”. Add to tube

“A”

•

11.5ml of 40%/7.5%

•

80 µI (10%) APS

•

5 µl TEMED

2. Add to tube “B”:

•

11.5ml of 60%/7.5%

•

80 µI (10%) APS

•

5 µI TEMED

3. Pour solution "B" into right side of gradient maker,(GM-40), and open interior

valve to allow air bubble to escape. Let as much as 1 ml "B" solution BACK-

FLOW into left side of gradient maker. Decant the 1ml back into right side with

pasteur pipette. Remove any residual solution with absorbent paper.

4. Add solution “A” to left side of gradient maker.

5. Turn on magnetic stirrer.

6. Exit tube should be attached to near side of gel plate with tape.

7 Open inside (V-1) valve first, then outside (V-2) valve to start flow.

8. Gel volume is 23ml, using the 0.75mm spacers. Allow 20-30 minutes for gel

polymeraztion. If gel volume is not enough to fill gel sandwich, use 0% to “top-

off”.

Go to Section 4 for Gel Running Preparation

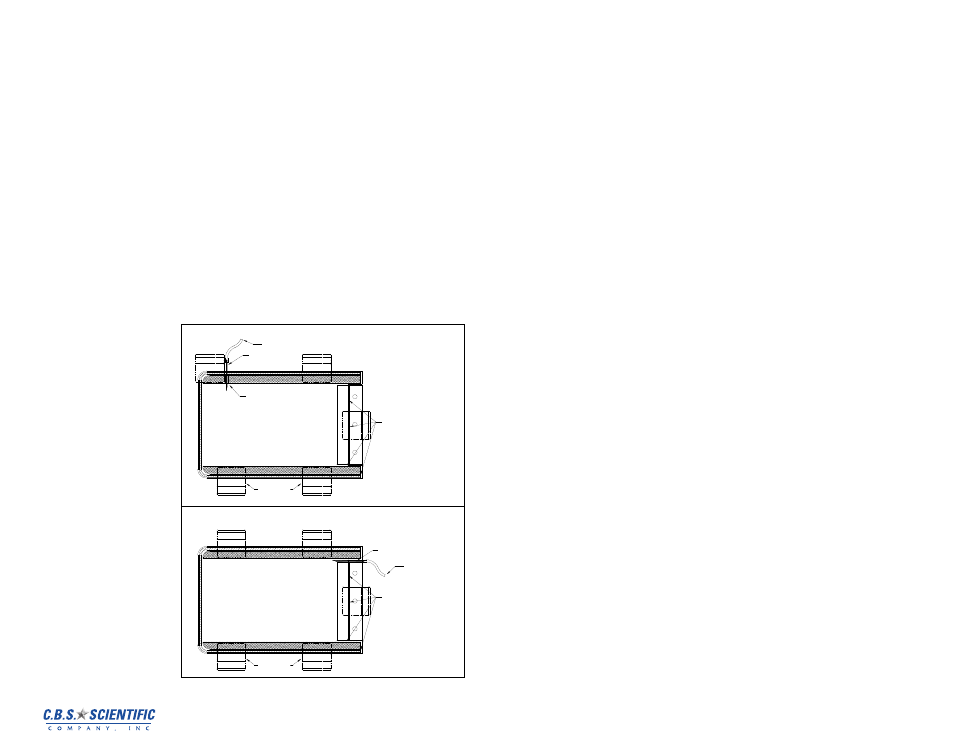

FIGURE 1

FIGURE 2

1.0mm AND THICKER

.75mm AND THINNER

PERPENDICULAR GEL CASTING

TO GRADIENT MAKER

20 GAUGE NEEDLE

SEAL WITH AGAROSE

HOLE THROUGH SPACER

GEL PLATE

CLAMPS

TO GRADIENT MAKER

20 GAUGE NEEDLE

SEAL WITH AGAROSE

GEL PLATE

CLAMPS

3 4 Perpendicular Gel Casting

NOTE: Prior to casting, mark the notched glass plate to designate which side is the

‘inside’ and ‘outside’. The same side of the notched plate should always sit against the

reservoir gasket.

1. For perpendicular gel casting, locate the spacer which has a channel machined

into it on one end which will be referred to as the “channel spacer”. The gel

sandwich will be cast on its side, with the channel spacer on top and the channel

further away from the single well comb (see figure 1 for casting gels 1.0mm and

thicker, see figure 2 bottom for casting gels .75mm or thinner).

2. Follow the Gel Wrap instructions 1-5 (pages 16-17),

making sure to use the

channel spacer

3. Insert single well comb into glass notch. A small amount of agarose is needed in

two places once the gel sandwich is placed on its side, both places are located

on the lower

corner where the single well comb interfaces the spacer, and on the

other side of the spacer where it interfaces the gel wrap.

4. Once the agarose has

set, insert the gradient

maker outflow tube tipped

with a 20ga. through the

Gel Wrap and into the

“channel” (figure 1), or

space created between

the horizontal spacer and

the comb (figure 2). You

may use the same piece of

Gel Wrap many times (20-

30) for the perpendicular

gels: do not use a piece

of Gel Wrap Gasket for

Vertical casting after you

have poked a hole in it for

perpendicular casting—it

will leak.