Dggek-2001 – C.B.S. Scientific DGGEK-4801 User Manual

Page 4

6

7

www.cbsscientific.com

Cipher DGGE Instructions 2/28/14

1.3

Safety

Power to the DGGE systems is to be supplied by an external DC voltage power supply

that must be ground isolated so that the DC voltage output floats with respect to

ground. For any power supply used, the maximum specified operating parameters for

the units are:

Maximum Limits

250 VDC voltage

30

watts

power

80

mA

current

70°C ambient temperature

Current to the unit, provided from the external power supply, must enter the unit

through the lid assembly, providing a safety interlock to the user. DC current to the unit

is broken when the lid is opened.

Do not attempt to use the unit without the safety

lid. Always turn the power supply off before removing the lid, or when working

with the unit in any way. Follow safety precautions specified by the power supply

manufacturer.

Input Power: Mains to safety interlock

Depending on country of destination, input voltage from mains electrical supply are as

follows: 110-120VAC @ 50/60Hz/5 Amps or 200-240VAC @ 50/60Hz/5 Amps. Country

specific power cords or CE approved adapter kits are supplied with each system.

Warning: Do NOT turn on Heater/Stirrer until tank has been filled with buffer!

SECTION 2

DGGEK Unit Set-Up

2 1 Unpacking Instructions

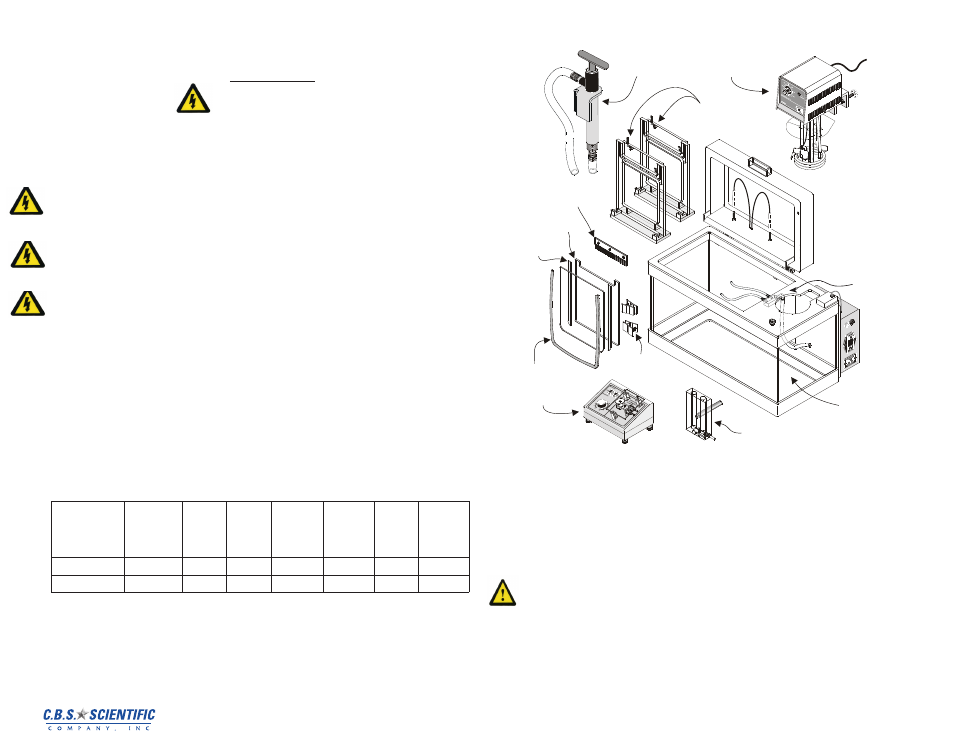

1) Unpack the DGGE Tank Assembly and place on level surface in an approved location.

Using figure 2-1 verify that your DGGEK-4001 or DGGEK-4801 System comes

complete with the following components:

• EPS-300 X Power Supply (not pictured)

• Peristaltic Mini-Pump for gel casting

• Lower Reservoir/Acrylic tank/safety interlock/ with 2 black leads inside lid

• Heater/Stirrer/By-pass pump (Controller) - factory-mounted onto DGGE tank

• Gel cassette(s), combs, spacer sets, Gel Wrap

™

gaskets, and glass plates sets as

specified in chart below:

• 1 Gradient maker, 20mls per side, Cat. # GM-40

• White spring clamps

• Buffer siphon pump with tubing, Cat# BSP-1000

• 2 Conversion Plates (not shown) for running 1 gel at a time on dual cassette (for

DGGEK-4801 only)

Figure 2-1

Heater

Stirrer

Buffer Siphon

Pump Assembly

Vapor

Shield

Thermometer

DGGE

Tank

Single

Cassetes

Comb (2)

Spacers

(2 pairs)

Glass Plate

Assembly(2)

Clamps

Mini-Pump

(Optional)

GM-40

Gelwrap

® (2)

Buffer recycling

manifold

2. Open the lid and confirm the following:

a) Two lengths of small bore silicone tubing for buffer cycling are already attached

to the buffer recycling manifold outlets

b) A single length of large bore tubing from the By-Pass Pump is connected to the

barb-fitting on the plastic manifold.

DGGEK-2001

2 2 Filling DGGE tank with Buffer

1) Fill the tank with running buffer (see Section 6 for buffer formulations) to minimum

level. This requires 32 liters of buffer.

Use distilled or RO water when making

buffer

Type of Gel

Cassette(s)

# of

Sample

Well

Combs

# of

1-well

Combs

# of Gel

Wrap ™

Spacer

Sets

# of Per-

pendicular

Spacer

Sets

# Gel

Wrap™

Gaskets

# glass

Plate Sets

DGGEK-4001

4 single

4

4

4

4

8

4

DGGEK-4801

4 dual

8

8

8

8

16

8