Adjustment table 2, Tank example, Figure 3 – Auto Meter 1501 User Manual

Page 2

STEM

"B" Length

Adjustment Table, INCH

TANK

DEPTH

FLOAT ARM

"A" Length

Adjustment Table, MILLIMETER

STEM

"B" Length

TANK

DEPTH

FLOAT ARM

"A" Length

6

6

1

⁄

2

7

7

1

⁄

2

8

8

1

⁄

2

9

9

1

⁄

2

10

10

1

⁄

2

11

11

1

⁄

2

12

12

1

⁄

2

13

13

1

⁄

2

14

14

1

⁄

2

15

15

1

⁄

2

16

16

1

⁄

2

17

17

1

⁄

2

18

18

1

⁄

2

19

19

1

⁄

2

20

20

1

⁄

2

21

21

1

⁄

2

22

22

1

⁄

2

23

23

1

⁄

2

24

3

5

⁄

8

4

4

3

⁄

8

4

3

⁄

4

5

1

⁄

8

5

3

⁄

8

5

3

⁄

4

6

1

⁄

8

6

1

⁄

2

6

7

⁄

8

7

1

⁄

4

7

1

⁄

2

7

7

⁄

8

8

1

⁄

4

8

5

⁄

8

9

9

3

⁄

8

9

3

⁄

4

10

10

1

⁄

2

10

3

⁄

4

11

1

⁄

4

11

1

⁄

2

11

3

⁄

4

12

1

⁄

4

12

1

⁄

2

12

7

⁄

8

13

1

⁄

4

13

1

⁄

2

13

7

⁄

8

14

1

⁄

4

14

1

⁄

2

15

15

3

⁄

8

15

3

⁄

4

16

16

3

⁄

8

152 mm

165

178

191

203

216

229

241

254

267

279

292

305

318

330

343

356

368

381

394

406

419

432

445

457

470

483

495

508

521

533

546

559

572

584

597

610

92 mm

102

111

121

130

137

146

156

165

175

184

191

200

210

219

229

238

248

254

267

279

286

292

299

311

318

327

337

343

352

362

368

381

391

400

406

416

89 mm

95

102

108

114

121

127

133

140

146

152

159

165

172

178

184

191

197

203

210

216

222

229

235

241

248

254

260

267

273

279

286

292

299

305

311

318

3

1

⁄

2

3

3

⁄

4

4

4

1

⁄

4

4

1

⁄

2

4

3

⁄

4

5

5

1

⁄

4

5

1

⁄

2

5

3

⁄

4

6

6

1

⁄

4

6

1

⁄

2

6

3

⁄

4

7

7

1

⁄

4

7

1

⁄

2

7

3

⁄

4

8

8

1

⁄

4

8

1

⁄

2

8

3

⁄

4

9

9

1

⁄

4

9

1

⁄

2

9

3

⁄

4

10

10

1

⁄

4

10

1

⁄

2

10

3

⁄

4

11

11

1

⁄

4

11

1

⁄

2

11

3

⁄

4

12

12

1

⁄

4

12

1

⁄

2

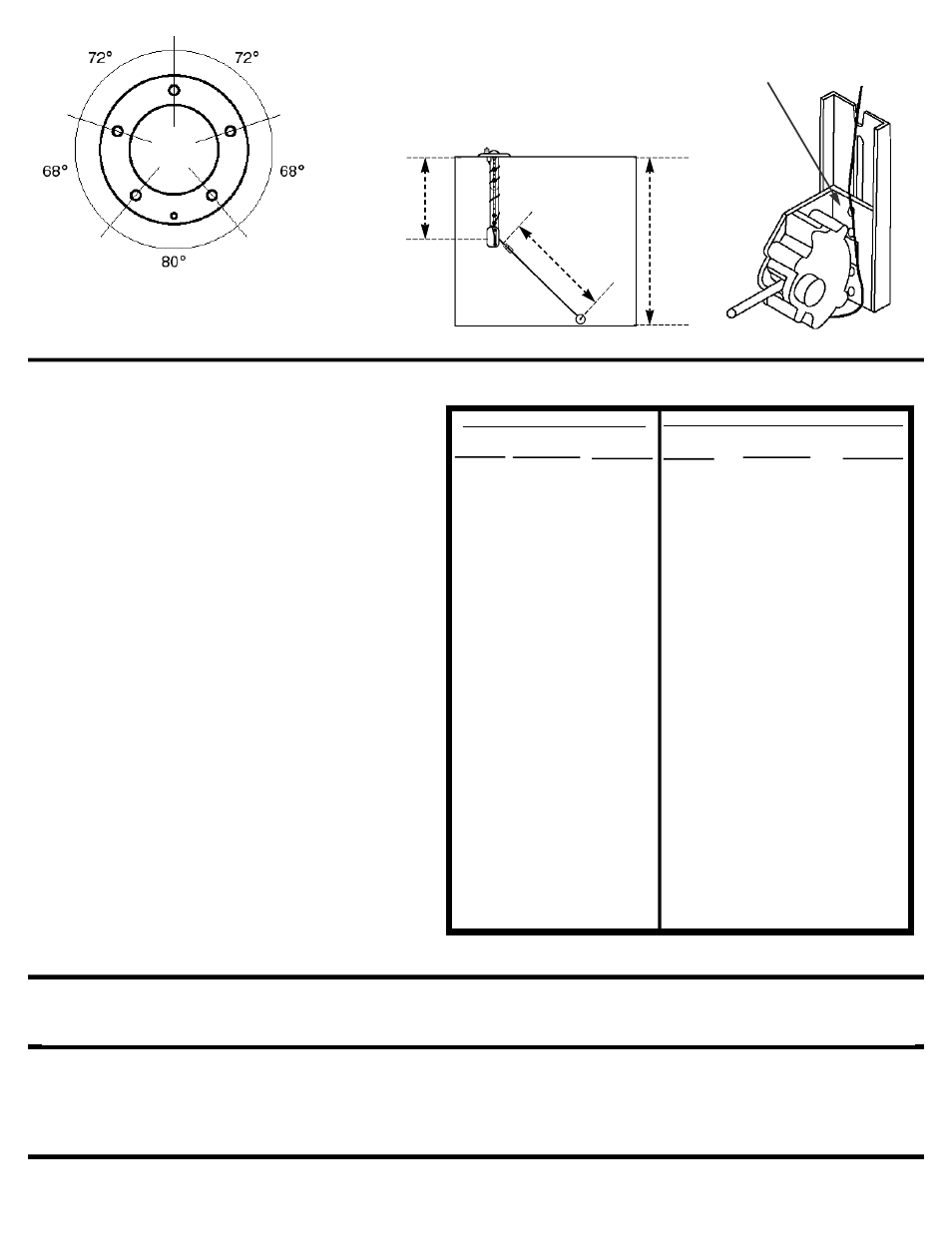

These fuel level senders are both equipped with a five hole

mounting flange. If your vehicle uses a six hole flange, an

adapter plate will be required. Please contact Customer

Service at the phone number below.

IMPORTANT:

Adjustment Table 2

Tank

Example

"B" Stem

Tank

Depth

SIDE VIEW

"A" Float

.....

Arm

Note:

Gasket can also be used as a template

for the mounting hole location.

TYPE “2”

15. Measure tank depth where the new fuel sender will be installed. Refer then to

ADJUSTMENT

TABLE 2 for correct lengths of float arm (Length “A”) and stem

(Length “B”). Measure, mark, and cut the stem to the correct length. Slide float

up float arm until the outer edge of the float is 3/16” (5mm) less than the float

arm length (Length “A”). Mark and cut off any remaining length of the float arm

extending over 1/8” inch past the push-on retainer.

16. Secure the case on the stem. The case should be secured 1/4” (6mm) above

the bottom of the stem. Be sure to place the wire between the case and bracket,

NOTthe bracket and the stem See FIGURE 3.

17. Slide the gasket over the float arm and sending unit to fit flat against the

underside of the mounting plate. Place the fuel sender in the fuel tank and align

the five holes in the sender flange with the holes in the fuel tank. The five

mounting holes are not equally spaced and will only line up in one angular

position. This allows repositioning of the float arm relative to the mounting holes

every 90°. If necessary to rotate the sending unit for your installation, loosen the

brass nut on the top of the mounting plate enough to allow the stem to rotate.

Make sure to rotate the stem in 90° increments to insure clearance of the float

arm with the tank wall.

18. Check for adequate clearance between float and fuel tank wall. (By holding fuel

level sender up along side of the fuel tank, you can better check for clearance of

vertical tank wall). If the tank wall interferes with the travel of the float arm

loosen the stem mounting nut and rotate the stem to a position where the float

will clear the tank wall.

19. Place the fuel level sender back in the fuel tank and check for clearance between

the float and the bottom of the tank. The float can not touch the bottom of the

tank. If the float does touch the bottom of the tank, double check the tank depth,

float arm length and stem length. Make the appropriate adjustments to the

sender.

20. Tighten all of the fuel sender ’s fasteners including the stem mounting nut and

case adjusting screws.

21. Install the fuel level sender and gasket in the tank using the five flange screws.

Leak test this area to ensure a proper seal. If unsure how to perform any of the

above or below procedures, or are unsure of electrical wiring connections, seek

the services of a qualified technician.

22. Reconnect the wire from the fuel level gauge using a ring terminal to the sender

terminal on the top of the mounting plate. If the fuel tank is not metal or if it is

fastened to the vehicle with only straps, a separate wire from one of the five

flange screws to a good chassis ground is necessary.

23. Tighten all the sender ’s fasteners and reinstall the fuel tank in the vehicle.

Reattach the fuel line to the tank and tighten the drain plug.

FIGURE 3

Place wire between case and bracket.

12 MONTH LIMITED WARRANTY

Auto Meter Products, Inc. warrants to the consumer that all Auto Meter High Performance products will be free from defects in material and workmanship for a period of twelve (12) months from date of the

original purchase. Products that fail within this 12 month warranty period will be repaired or replaced at Auto Meter's option to the consumer, when it is determined by Auto Meter Products, Inc. that the product

failed due to defects in material or workmanship. This warranty is limited to the repair or replacement of parts in the Auto Meter instruments. In no event shall this warranty exceed the original purchase price of

the Auto Meter instruments nor shall Auto Meter Products, Inc. be responsible for special, incidental or consequential damages or costs incurred due to the failure of this product. Warranty claims to Auto Meter

must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only to the original purchaser of product and is non-transferable. All implied warranties shall be limited in

duration to the said 12 month warranty period. Breaking the instrument seal, improper use or installation, accident, water damage, abuse, unauthorized repairs or alterations voids this warranty. Auto Meter

Products, Inc. disclaims any liability for consequential damages due to breach of any written or implied warranty on all products manufactured by Auto Meter.

SERVICE

For service send your product to Auto Meter in a well packed shipping carton. Please include a note explaining what the problem is along with your phone number. Please specify when you

need the product back. If you need it back immediately mark the outside of the box "RUSH REPAIR," and Auto Meter will service product within two days after receiving it. ($10.00 charge will

be added to the cost of "RUSH REPAIR.") If you are sending product back for Warranty adjustment, you must include a copy (or original) of your sales receipt from the place of purchase.

F O R S E RV I C E S E N D TO: A U TO M E T E R PRODUCTS, INC.

413 W. Elm St., Sycamore, IL 60178 USA (815) 895-8141

Email us at [email protected]

2650-421B 11/24/98