Inspect site caution – Anchor NAVI-TRAC 30 WIDE GABLE-END User Manual

Page 3

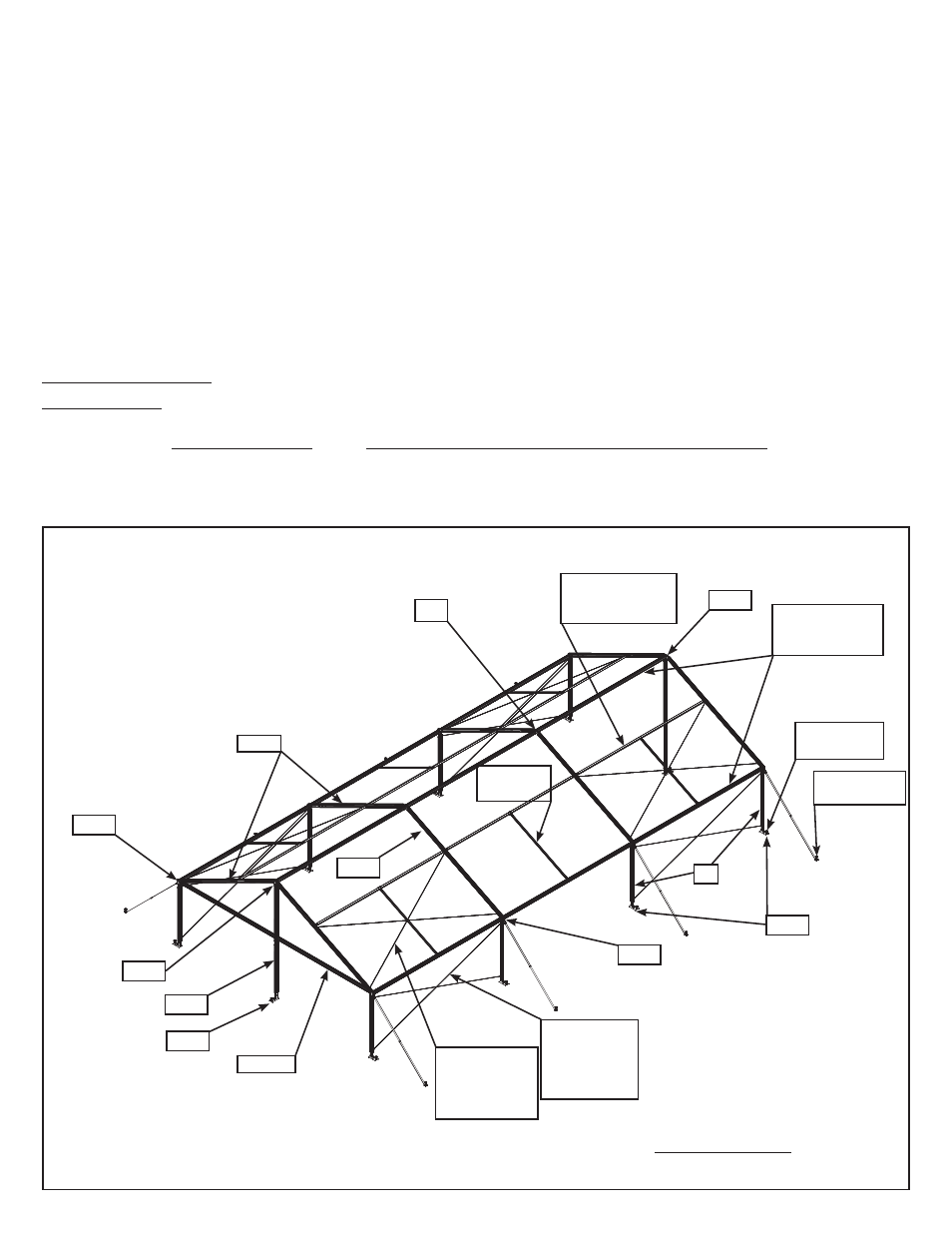

30’ Gabled Navi-Trac Frame Terminology

INTRODUCTION:

Like the hip-end version, the gabled end NAVI-TRAC frame is made up of extruded aluminum members joined by weldments. The alu-

minum frame members themselves are extruded with channels into which the NAVI-TRAC fabric “kedar” is fed. However, the gabled

end version of the Navi-Trac differs from the Hip End version in a number of ways:

1. All the beams are parallel to each other.

2. Beam base plates are hinged for pivoting to a vertical position. End Upright plates are fixed, non-pivoting.

3. The eave fittings are the MCW style that allows a simple drop-in action for purlin installation, rather

than the slip joint of the hip end configuration.

4. Fabric middle bays are installed into the channels of adjacent beams one bay at a time.

5. Gabled End fabric is intalled simply into the outer channel of the end beams and tensioned to the

Gabled End uprights.

6. Corner guys are in one direction only, parallel to the beams.

NOTE: It is possible to combine the hip end and gabled end styles within one building unit (see kit #3); however this assembly manual

focuses on the gabled end configuration only. The last few pages describe the hip/gabled combination and refer the customer to the

hip end assembly manual for the hip end part of the building unit.

ER10, 15, or 20

Dependent upon

mid bay width.

EW15

R16-2

P1, P2 OR P3

Dependent upon

mid bay width.

UG-15

U8

BFW

BHW

MCW

RWE

RW

XRB

UGT

X-4, 5 or 6

Dependent

upon mid bay

width.

X-1, 2 or 3

Dependent

upon mid bay

width.

30” Stake at

Base Plates

42” Stake for

each Guy

P1 for 20’

bay only.

MCW

See Component List Table on Pages 5 &

6 for component descriptions.

3

INSPECT SITE

CAUTION:

Consult your local utility locator service or the National Utility Locating Contractors Association (NULCA) prior to

installation.

Prior to actual tent assembly, be sure to look up, down, above & below for obstacles, pipes, wires, trouble, etc.