Brake lathes – AMMCO 7000 Disc Rotor Lathe User Manual

Page 18

Maintenance and Service

Note: Refer to LATHE COMPONENTS.

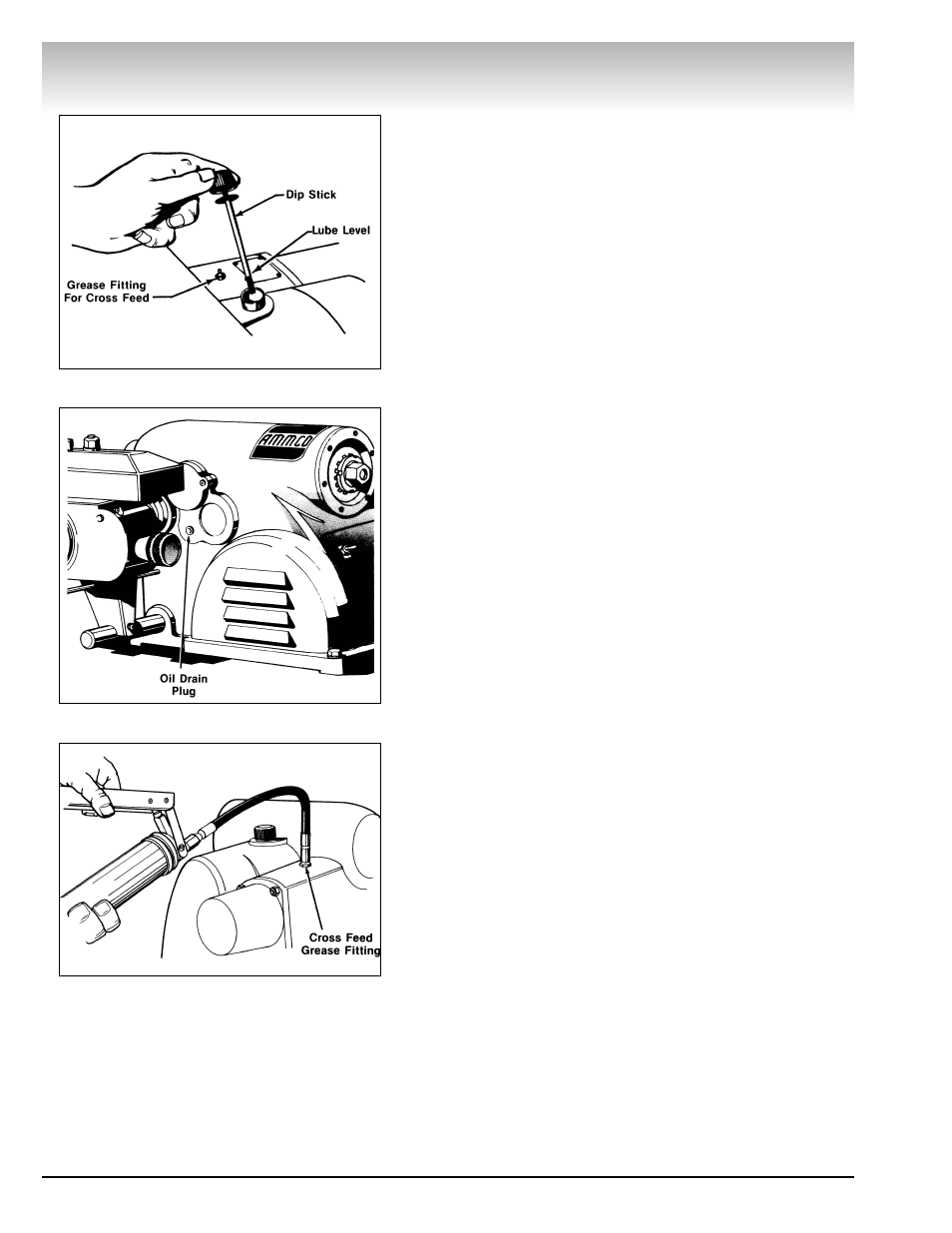

Oiling

The lathe is shipped from the factory with the correct amount

and type of oil. Refill as necessary with EP-80-90 gear oil and

check the oil level often., Fig. C 1.

Every 500 hours drain the oil and refill to the dipstick level with

clean EP-80-90 gear oil. To drain the oil, remove the socket head

drain plug located on the front of the lathe to the right of the

cross feed assembly, Fig. C 2.

Cross Feed - Once a month pump automotive chassis grease

into the cross feed grease fitting until it begins to come out of

the relief slot at the base of the fitting. CAUTION: Use a HAND

GREASE GUN ONLY, a high pressure gun can burst the lathe

casting, Fig. C 3.

Cleaning

Keep the lathe as clean as possible for trouble free operation

as well as safety and longer lathe life. Use a brush to sweep

metal chips and dust off the lathe. DO NOT USE COMPRESSED

AIR TO BLOW THE LATHE CLEAN. Chips and dust could be

driven between machined parts and into bearings causing

undue wear.

Brake Lathes

12 • AMMCO 7000 Brake Lathes

Figure C1

Figure C2

Figure C3