Brake lathes – AMMCO 7000 Disc Rotor Lathe User Manual

Page 14

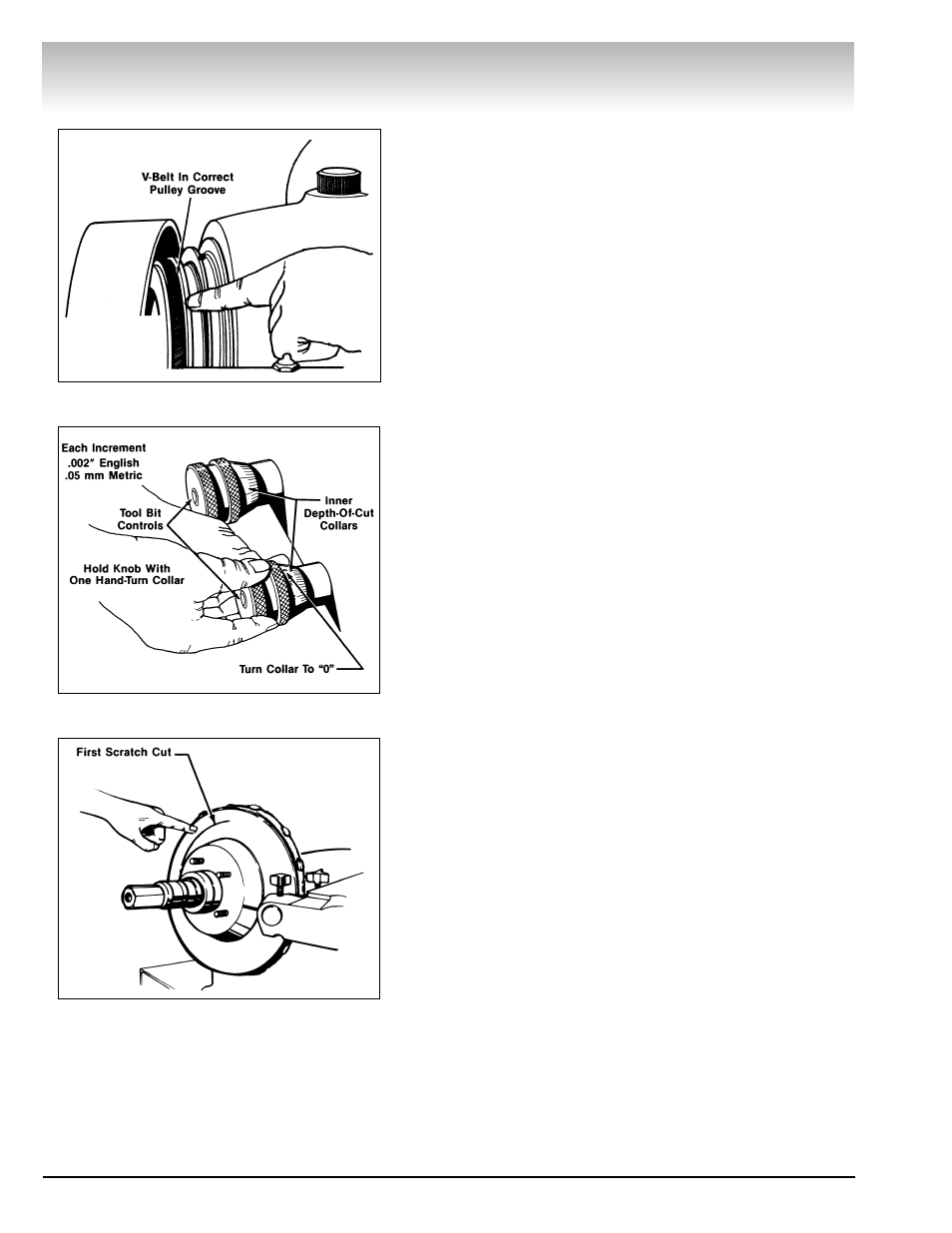

4. Adjust the drive belt to match the rotor size. Use the outer

pulley groove for all passenger car and light truck rotors, Fig. B

12. Choose one of the inner grooves when machining medium

duty truck rotors.

5. Make sure that the tool bits clear the rotor faces and the

silencer band. Give the rotor a full turn by hand and start the

lathe.

6. Turn each tool bit control (the outer knurled knobs) clock-

wise until the tool bits just contact the rotor faces. When the

tool bits have made contact, rotate each of the inner depth-of-

cut collars to zero and back the tool bits away from the rotor.

From this point on all tool adjustments will be made with the

tool bit controls, Fig. B 13. The inner depth-of-cut collars will be

the reference and should not be moved.

7. Turn the cross feed handwheel until the tool bits are at mid-

point of the rotor face. Turn the left hand tool bit control until the

tool bit contacts the rotor surface and makes a scratch cut no

deeper than .001", Fig. B 14.

Brake Lathes

8 • AMMCO 7000 Brake Lathes

Figure B14

Figure B12

Figure B13