Brake lathes – AMMCO 7000 Disc Rotor Lathe User Manual

Page 11

Cross Feed - The cross feed draws the twin tool bits across the

face of a brake rotor when the cross feed drive is engaged. The

cross also be operated manually using the cross feed hand-

wheel.

Feed Speed - Feed speed refers to the number of thousandths

of an inch the cutting tools move across the face of the rotor per

revolution of the spindle. The cross feed speed control adjusts

the feed rate from .002" (.05 mm) to .004" (.10 mm) to .006" (.15

mm) per spindle revolution.

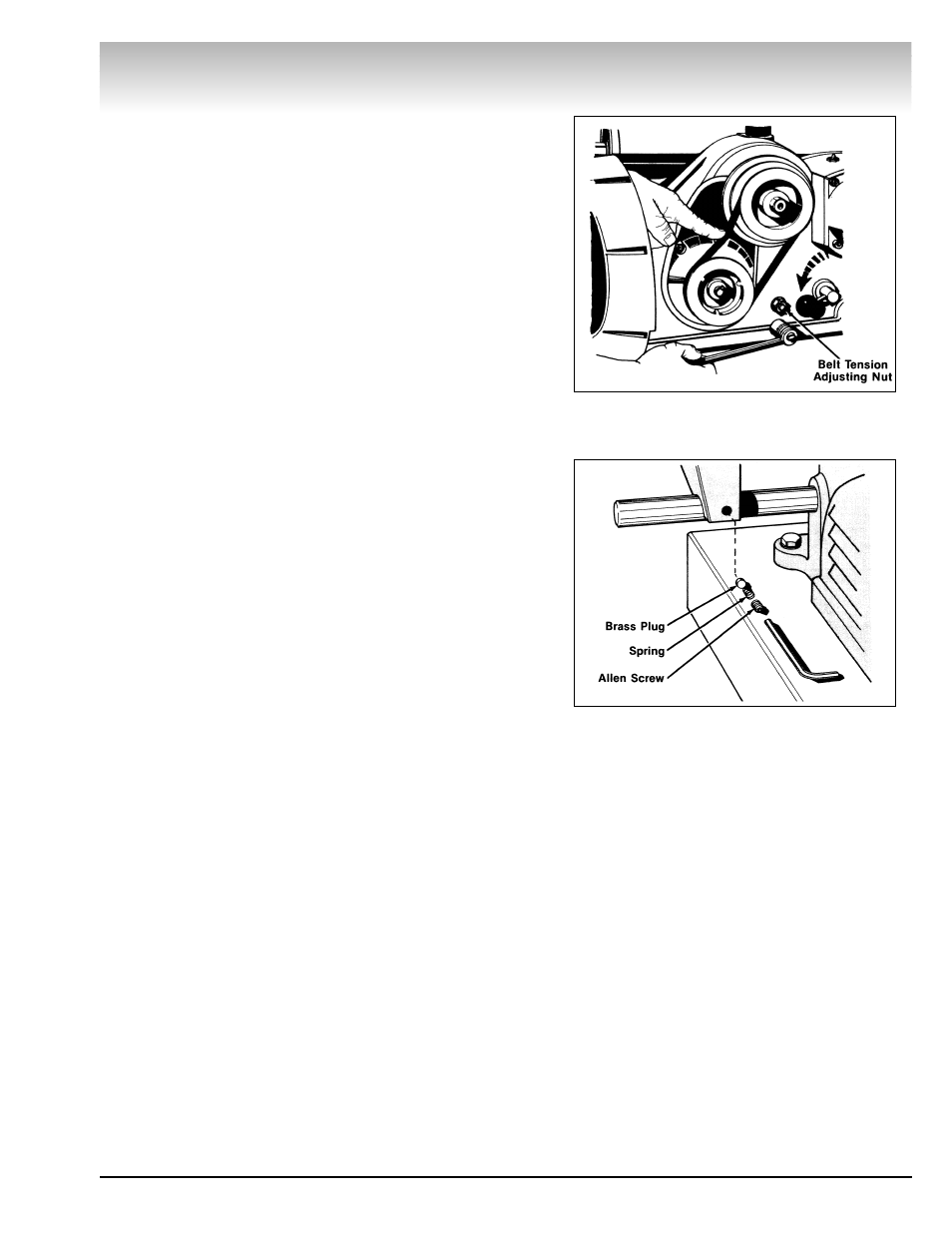

V-Belt Tension - When properly adjusted, the V-Belt should have

1/4" - 1/2" of slack. To adjust the tension, loosen the tension

adjusting nut so the weight of the motor pulls the V-Belt snug

and rotate red knob to its furthest counterclockwise position.

Push the belt in 1/4" - 1/2" on one side and tighten the nut, Fig.

B 5.

Cross Feed Leg Tension -- Be sure the brass plug and spring

are under the allen screw. (if the cross feed has been pulled out

beyond the end of the guide bar, the plug and spring may have

been lost.) Replace the plug and spring, Fig. B 6, then snug the

allen screw all the way down then back it off 1/8" of a turn.

Tool-Bit Holder Adjustment (Preliminary Cleaning) - Refer to

parts identification manual for nomenclature.

Before adjusting the tool-bit holders on a used twin cutter, the

following steps should be performed.

1. Be sure the tool-bit holder bores in the twin cutter body are

clean along with the tool-bit holders and tool-bit assemblies.

2. Replace the brass plugs if the original plugs are “mush-

roomed” or worn.

3. Clean the threads of the lock knob holes by running a tap

through them.

(Adjusting Tool-Bit) - Refer to parts identification manual for

nomenclature.

1. Loosen and back off the hex nut locking the locating screw

in position.

2. Loosen and back off the lock knob.

3. Firmly tighten the locating screw to align the tool-bit holder

by its locating groove.

4. Simultaneously loosen the locating screw and tighten the

tool-bit holder lock knob until the locating screw is loose and the

lock knob is tight.

5. Screw the locating screw in until it is snug, then back it off

1/8 to 1/4 of a turn.

6. Hold the locating screw in this position and tighten the hex

nut to lock the screw in place.

7. Turn the outer knurl of the twin cutter control left and right

to check for a smooth, free movement. Repeat the procedure

for the other tool-bit holder.

Brake Lathes

AMMCO 7000 Brake Lathes • 5

Figure B5

Figure B6