Brake lathes – AMMCO 7000 Disc Rotor Lathe User Manual

Page 12

Reconditioning Disc Brake Rotors

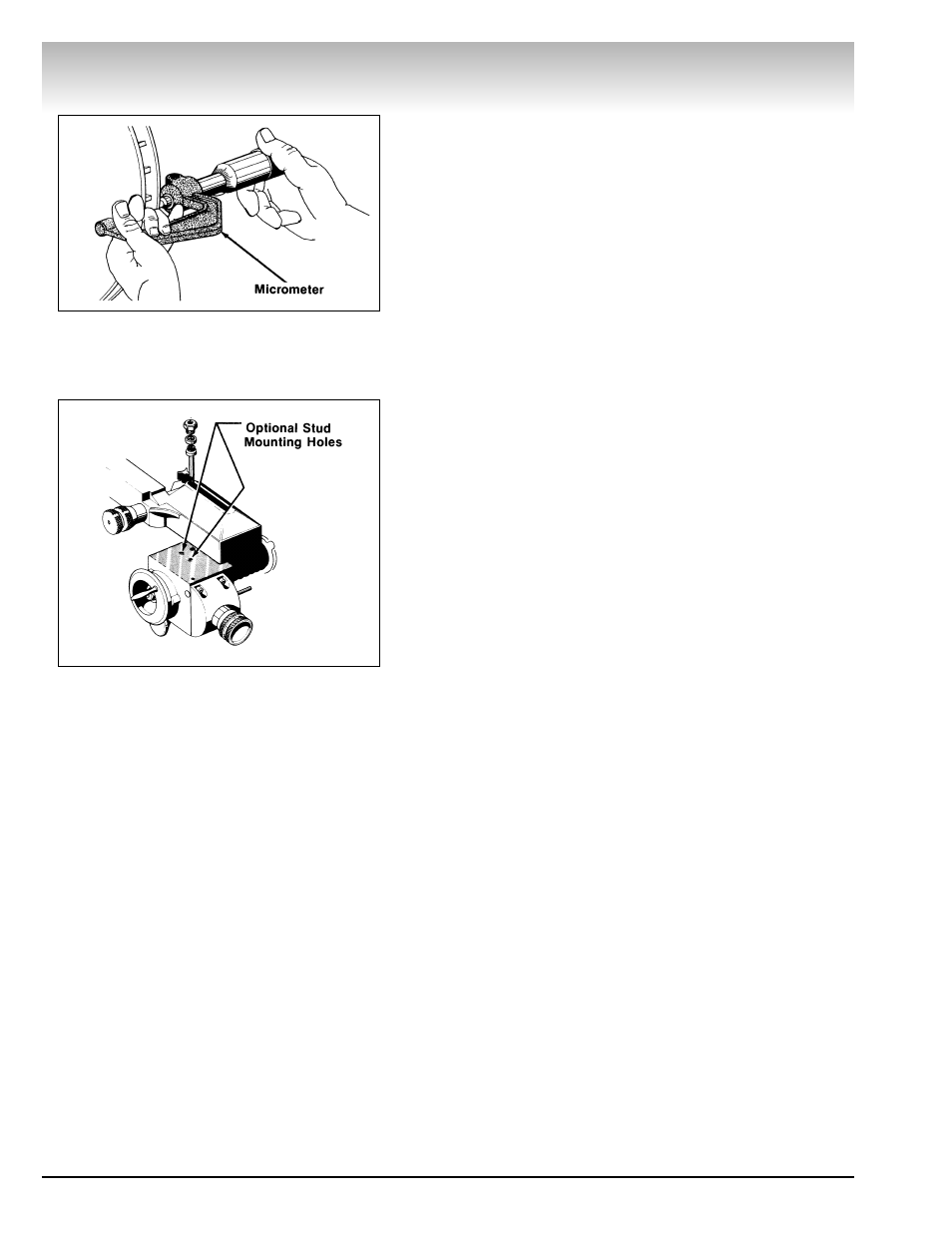

Each brake disc should be carefully inspected for SCORING,

RUST RIDGES (at the inner and outer circumference of the

rotor), and HARD SPOTS. Any excessive wear or deformity

should be noted and, if not within acceptable limits, the rotor

should be replaced. Use a micrometer to check the thickness of

the rotor at no less than three points around the circumference

about 1" (25.4 mm) in from the outer diameter, Fig. B 7. If the

rotor thickness varies between readings, it should be machined;

however, if the thickness is less than the minimum established

by the car manufacturer (or if it will be less after reconditioning),

the rotor should be replaced.

Note: Most often the discard thickness dimension is cast into

the rotor, not the minimum machine to thickness.

Mount the twin cutter on the cross feed with the stud bolt

extending through the cast slot. In some applications the stud

bolt may have to be positioned in one of the alternate stud

mounting holes, Fig. B 8. To prevent contamination of the gear

box position set screw in unused hole. To secure the twin cut-

ter use the nut and washer assembly and tighten firmly.

Rotor Mounting

Fig. B20, TYPICAL ROTOR MOUNTING CONFIGURATIONS is

a model example of many of the mounting configurations nec-

essary to meet the requirements of brake rotor machining.

Inspect the rotor hub for loose or damaged bearing races and

replace parts as necessary. Hubbed rotors are mounted on the

taper adapters that fit into the bearing races. Hubless rotors use

a cone in the center hole and a hubless adapter on each side of

the rotor. Spacers are used to fill out the arbor shaft so that the

arbor nut can be tightened. The adapters, cones, and spacers

supplied with your lathe will allow you to recondition the major-

ity of rotors on today’s vehicles. Optional adapters, cones, and

spacers are available to meet special needs.

Note: Adapters may also be used as spacers to fill out the

arbor if care is taken to prevent damage to their machined sur-

faces. The patented self-aligning spacer prevents diagonal thrust

on the adapters. The self-aligning spacer should always be used

adjacent to the arbor nut.

Brake Lathes

6 • AMMCO 7000 Brake Lathes

Figure B7

Figure B8