JLG 40RTS ANSI Service Manual User Manual

Page 20

SECTION 2 - PROCEDURES

2-4

– JLG Sizzor –

3120691

Relief Valves

Main relief valves are installed at various points within the

hydraulic system to protect associated systems and com-

ponents against excessive pressure. Excessive pressure

can be developed when a cylinder reaches its limit of

travel and the flow of pressurized fluid continues from the

system control. The relief valve provides an alternate path

for the continuing flow from the pump, thus preventing

rupture of the cylinder, hydraulic line or fitting. Complete

failure of the system pump is also avoided by relieving cir-

cuit pressure. The relief valve is installed in the circuit

between the pump outlet (pressure line) and the cylinder

of the circuit, generally as an integral part of the system

valve bank. Relief pressures are set slightly higher than

the load requirement, with the valve diverting excess

pump delivery back to the reservoir when operating pres-

sure of the component is reached.

Crossover Relief Valves

Crossover relief valves are used in circuits where the actu-

ator requires an operating pressure lower than that sup-

plied to the system. When the circuit is activated and the

required pressure at the actuator is developed, the cross-

over relief diverts excess pump flow to the reservoir. Indi-

vidual, integral relief’s are provided for each side of the

circuit.

2.6

COMPONENT FUNCTIONAL

DESCRIPTION

Piston Hydraulic Pump

The Sundstrand piston hydraulic pump is attached to and

driven by the engine. The pump is a 2.8 in.[3] (45.9 cm[3])

displacement piston pump that powers the drive motors.

Gear Hydraulic Pump

The John Barnes gear pump is “piggy-backed” to the pis-

ton pump, and operates all machine functions except

drive. The gear pump has a displacement of 0.6 in. [3]

(10.5 cm[3]).

Manual Descent Valve

The manual descent valve is located on top of the holding

valve on the lift cylinder. The holding valve is a normally

closed solenoid valve, and holds the platform in place

when raised. When activated, the valve opens to permit lift

down. The holding valve is connected to the manual

descent valve, which is connected to a cable which, when

pulled, manually opens the lift down port of the valve and

allows the platform to be lowered in the event hydraulic

power is lost.

2.7

SLIDING WEAR PADS

The original thickness of the sliding pads is 2.0 in. (50.8

mm). Replace sliding pads when worn to 1.87 in. (47.5

mm).

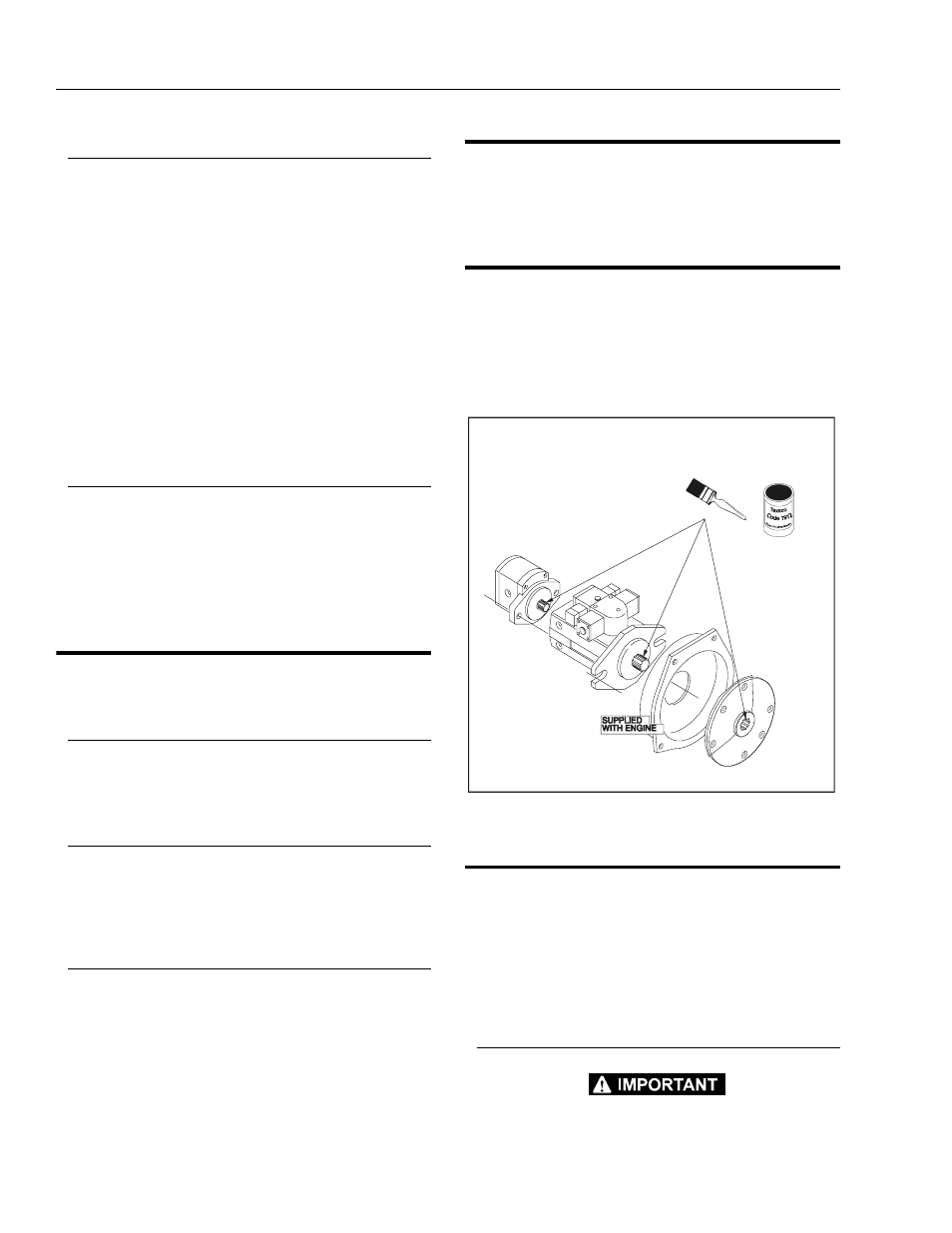

2.8

PUMP AND COUPLING LUBRICATION

To insure proper operation and a long service life for the

Hayes pump coupling, it is necessary to lubricate the

splines of the coupling any time the coupling is disassem-

bled or replaced. Lubricate the splines with Texaco Code

1912 Pump Coupling Grease ONLY. No other lubricant is

recommended.

2.9

CYLINDER CHECKING PROCEDURES

NOTE: Cylinder checks must be performed any time a cylin-

der component is replaced or when improper system

operation is suspected.

Cylinder w/o Counterbalance Valves - Steer

Cylinder, Axle Lockout Cylinder (If

Equipped)

OPERATE FUNCTIONS FROM GROUND CONTROL STATION

ONLY.

Figure 2-1. Pump and Coupling Lubrication