6 pump-motor assembly - service procedure, General, Pump/motor/reservoir - remove/install – JLG 9MP Service Manual User Manual

Page 36: Pump-motor assembly - service procedure -6

SECTION 4 - CONTROL COMPONENTS

4-6

– JLG Lift –

3121163

4.6

PUMP-MOTOR ASSEMBLY -

SERVICE PROCEDURE

General

The following is a complete tear-down/re-assembly of the

machines’ pump/motor assembly. No internal parts to the

hydraulic pump are serviced by JLG except for a pump

installation seal kit. Also the only parts serviceable internal

to the pump electric motor is the motor brush kit.

NOTE: During reassembly of the pump/motor assembly,

apply a liberal coat of JLG recommended hydraulic

fluid to all seals and o-rings.

Also keep all internal metal parts clean and coated

with hydraulic fluid to prevent surface corrosion.

JLG recommends replacing all seals and o-rings

when disassembling and reassembling the pump/

motor unit.

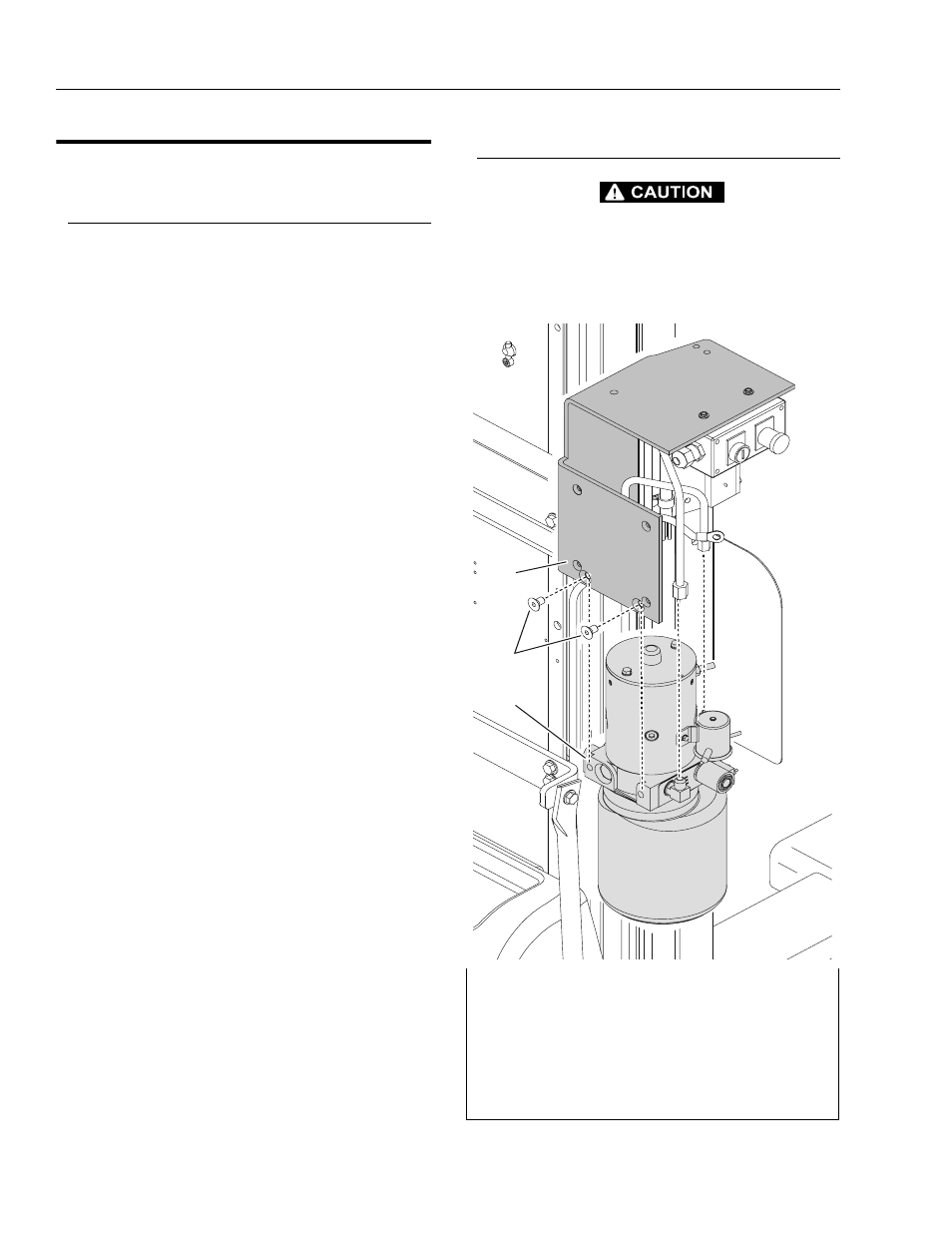

Pump/Motor/Reservoir - Remove/Install

BE CERTAIN THE MAST IS FULLY LOWERED BEFORE REMOVING

ANY HYDRAULIC LINES FROM THE PUMP UNIT. WEAR PROTEC-

TIVE GEAR WHEN WORKING AROUND PRESSURIZED HYDRAULIC

LINES. REMOVE CONNECTIONS CAREFULLY AND CAP ALL

LINES AND PORTS WHEN DISCONNECTED.

• Remove the ground control station cover, see Section 4.2.

• Remove the extend/return hydraulic lines.

• Remove all electrical connections from pump assembly.

1. Pump Assembly

3. Pump Mount

2. Mounting Screws (a)

Notes: (a) Apply Loctite #242 to mounting screw threads before

tightening.

1

2

3