Integral brake check, Integral brake check -11 – JLG 660AJ Service Manual User Manual

Page 55

SECTION 3 - CHASSIS & TURNTABLE

3121616

– JLG Lift –

3-11

9.

Place Input Carrier Sub-Assembly (3A) on Output Sun

Gear (11) splines. Drop Input Sun (10) in mesh with

planet gears for specific ratios, if required. (No timing

required).

10.

Grease O-Ring (17) and insert in groove in Cover Sub-

Assembly (6).

11.

Install Cover Sub-Assembly (6) in Ring Gear (1E) counter-

bore and install Retaining Ring (6G) in groove in Ring

Gear (1E).

12.

Attach ID Tag (15) on unit using Drive Screws (16).

13.

Check disconnect, roll and air check unit, leak check

brake, and record release pressure.

14.

Insert Plastic Plug (12) if applicable.

Integral Brake Check

1.

Using appropriate fittings, connect hydraulic line from

hand pump to brake port.

2.

Check brake is set by trying to rotate Input Shaft (9). This

can be accomplished by installing an appropriate tool

(any tool that can locate on splines of Input Coupling (7),

such as a mating splined shaft) into Input Coupling (7).

3.

Bleed brake. Increase hydraulic pressure gradually while

trying to rotate input until brake just starts to release.

Note this pressure. Make sure pressure falls into appro-

priate range below.

4.

Increase pressure to 1,000 psi and hold for 30 seconds to

check for leaks. Repair leaks if necessary.

NOTE: Make sure brake re-engages when pressure is released.

NOTE: When done, make sure Input Coupling (7) is centered in

Spindle (1A) to make installation of motor possible without

release of brake.

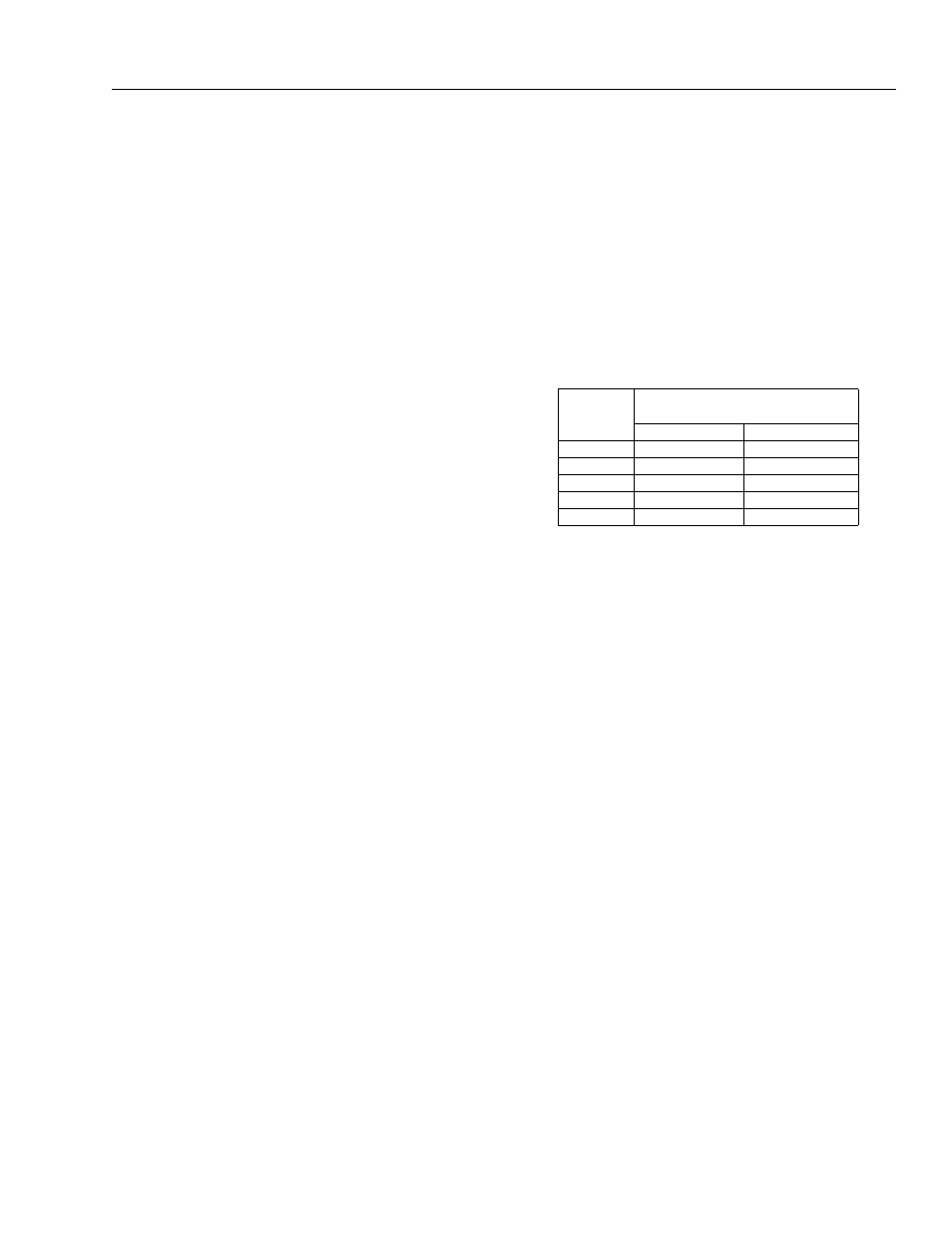

BRAKE

CODE

JUST RELEASE

PRESSURE RANGE

PSI

BAR

A

200-260

13.7-17.9

B

170-220

11.7-15.1

C

140-185

9.6-12.7

D

130-155

8.9-10.6

E

115-145

7.9-9.9