Advance Adapters 716640 User Manual

Page 2

JEEP CHAIN CONTROL CLUTCH LINKAGE

KIT FOR VEHICLES 1946-70

ADVANCE ADAPTERS INC.

P/N: 716640

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447

PAGE 2 OF 4

Telephone: (800) 350-2223

Fax: (805) 238-4201

Page Rev. Date:

05-17-01

SPECIAL NOTE:

The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components will void

any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly recommend that

you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components. We recommend that a service

manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are normally available at automotive dealerships

and parts stores.

INSTALLATION INSTRUCTIONS:

1.

Remove the cotter pins on the clutch release rod.

2.

Remove the pedal release rod.

3.

Remove the clutch linkage torque tube. This requires the removal of the (2) bolts from the outside of the frame

rails. Leave the ball pivot that mounts in the transfer case in position.

4.

Remove the clutch cable that mounts to the clutch fork.

5.

Inspect the stock clutch pedal arm and related parts for excessive wear. Check with your local Jeep Dealer for

replacement parts if necessary.

6.

Inspect the hole in the clutch arm for possible elongation Quite often, the solid linkage rod will develop a larger size

hole than the rod. The hole can be plug welded and re-drilled to 5/16" to avoid the purchase of a new pedal.

7.

Bolt the rod end

(P/N 716647)

to the inside of the pedal. Make sure the bolt clears the rod end bearing for sufficient

threads. The bearing must be on the transmission side of the arm.

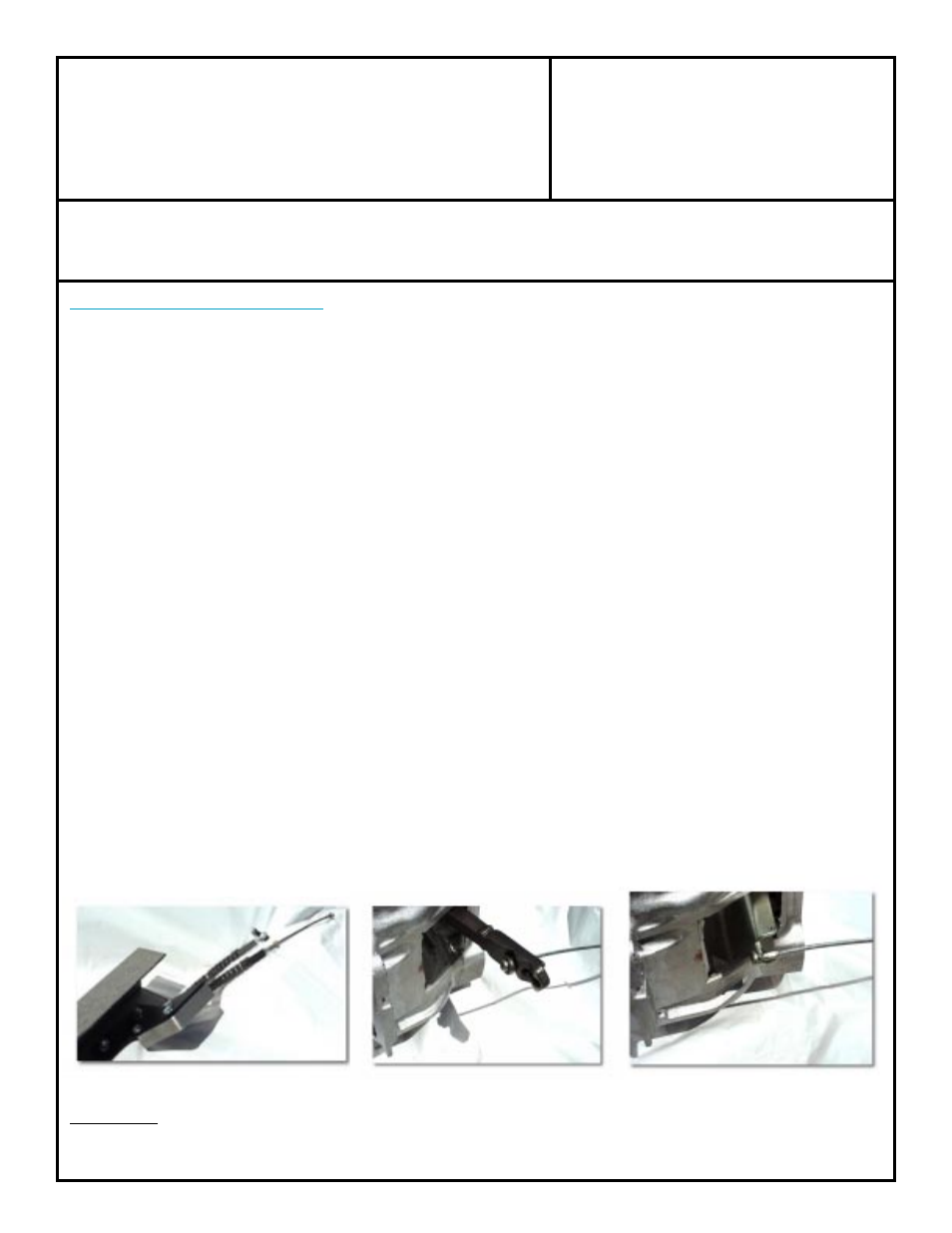

8.

The other end on the assembly can now be connected to the stamped steel Jeep clutch release fork. The ball end

simply slips into the groove on the fork (See Photo 3).

**If using the GM style cast iron clutch fork

(as shown

in Photo 2)

, simply slip the cable end through the hole in the fork, and pull enough through so that you have

access to the cable. Slip the ball converter over the cable. The coned portion will be facing the rear of the

vehicle. Pull the cable tight against the arm. The outside slot on the GM arm must also be trimmed for

frame clearance.

9.

Mount the sprocket into the chain so that it goes onto the bottom of the sprocket from the pedal, and then over the

top to the clutch.

10. Draw the sprocket assembly with the chain attached towards the rear of the vehicle. The bent portion of the steel

bracket fits in the lower part of the frame channel. Using a clamp, position the tension so that the clutch pedal has

approximately 3/4" to 1" free play or dead pedal.

11. Align the bracket so that it runs evenly on the lower inside edge of the frame rail. Use the bracket to locate the two

holes necessary for mounting. Drill the two holes through the frame rail and bolt firmly in position using flat washers

& lock washers. Make certain that the chain does not bind. If needed, the frame bracket may be bent to enhance

chain movement.

12. Using the connectors,

(P/N 716641)

and the jam nuts

(P/N 723131)

, make the final clutch adjustment to the desired

free play. Lock the jam nuts firmly to prevent slippage. The threads in the connectors must have a minimum of

3/4" thread engagement. On some models, a special adapter is furnished to attach 3/8" cable thread to 5/16"

connector thread.

13. All of the components used in the manufacturing of the chain control should require a minimum of lubrication and

maintenance.

14. As your clutch assembly wears, it may be necessary to make periodical adjustments to the linkage.

Photo 1

Photo 2

Photo 3