Advance Adapters 713093 User Manual

Page 3

ADVANCE ADAPTERS INC.

P/N: 713093

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447

PAGE 3 OF 6

Telephone: (800) 350-2223

Fax: (805) 238-4201

Page Rev. Date:

08-18-10

SPECIAL NOTE:

The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the

components will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion,

we strongly recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter

components. We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment.

These manuals are normally available at automotive dealerships and parts stores.

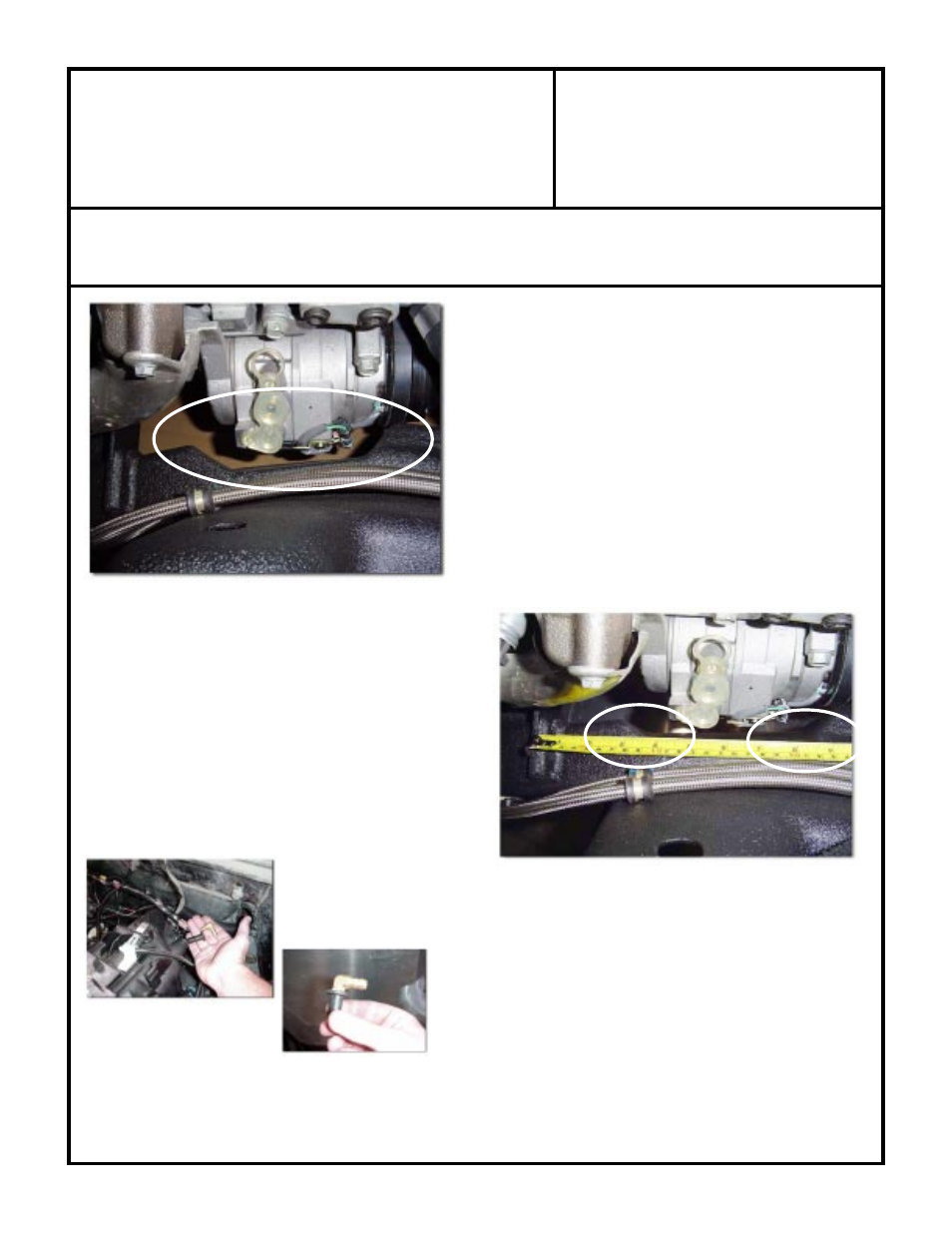

Vacuum Connection for Brake Booster:

You will notice that the Vortec block has no provision for a vacuum line for the brake

booster. There is a small port on the back of the intake manifold

that can be used. First, pull out the black plug on the intake mani-

fold by holding pressure on the gray ring. Once the plug is out,

drill and tap the black plug for a 1/8” pipe thread. Use a 90 degree

1/8” pipe by 3/8” barb adapter and thread it into the tapped plug.

Press the plug back into the manifold and attach the hose.

VORTEC GEN. III V8 SQ. BOLT

TJ WRANGLER MOTOR MOUNTS (WITH A/C)

becomes flammable. This caution applies to both the cutting

and welding portion of this instruction sheet. There are several

ways to remove metal from the frame. An abrasive cut-off

wheel does a great job of keeping the temperature of the cut

down, but it does take more time. A torch is very fast, but

keep an eye on how hot the frame is getting. If you are not

comfortable with the cutting, do not hesitate calling a certified

welder, or simply have it done for you. Keep a fire extin-

guisher close at hand, and wear all safety equipment.

When you feel comfortable with the notch in the frame, a

piece of scab plate MUST be fit and welded into place on the

frame to bring the frames integrity back. This should be made

out of a minimum of 5/16” plate. Make sure all surfaces are

clean from paint, slag, and any foreign objects. All edges should

meet with a minimal amount of gap between them. Again,

pay attention to the amount of heat you are putting on the

frame. Taking a small break to allow for cooling is a good

idea. TIP: Grinding the surface of a weld for “looks” is not

a bad ideal.

ONLY TAKE A MINIMAL AMOUNT OF

MATERIAL OFF!

It is very easy to grind too deep and not

even know it. Leaving the entire weld will assure that strength

is not being compromised on the scab plate. When done

correctly, this “clearance notch” should not become a “weak”

point. Please call at any point if there are any questions!

Note that these instructions are based around a truck engine

with truck accessories.