Advance Adapters 712583 User Manual

Advance Adapters For the car

ADVANCE ADAPTERS INC.

P/N: 712583

P.O. Box 247, 4320 Aerotech Center Way

Paso Robles, CA 93447

PAGE 1 OF 3

Telephone: (800) 350-2223

Fax: (805) 238-4201

Page Rev. Date:

03-26-08

KIT CONSISTS OF:

No.

Qty

Part No.

Description

SPECIAL NOTE:

The components packaged in this kit have been assembled and machined for specific type of conversions. Modifications to any of the components

will void any possible warranty or return privileges. If you do not fully understand modifications or changes that will be required to complete your conversion, we strongly

recommend that you contact our sales department for more information. This instruction sheet is only to be used for the assembly of Advance Adapter components.

We recommend that a service manual pertaining to your vehicle be obtained for specific torque values, wiring diagrams and other related equipment. These manuals are

normally available at automotive dealerships and parts stores.

1.

1

712583-BLK

BELLHOUSING

2.

1

716158

PILOT BEARING (

.670"

) (

For Ford Trans. Use #716193

)

3.

1

716170

PILOT BEARING (

.590"

)

4.

1

716176

GM THROW OUT LEVER

5.

1

716180

BALL PIVOT (

Installed

)

6.

1

716338

CLUTCH RELEASE ARM BOOT

7.

6

723730

S.H.C.S. 3/8"-16 x 1-1/4" LONG

8.

1

JP001

JEEP INSTRUCTION MANUAL

BUICK BELLHOUSING FOR USE WITH

JEEP T4, T5, SR4, & T176 TRANSMISSIONS

INSTALLATION INSTRUCTIONS:

This bellhousing is for use with the original Jeep 4 & 5 speed transmissions & Jeep T18 transmission. The bearing

retainer on the front of the transmission must pilot directly into the back of the new bellhousing. Make sure that the

input shaft of the transmission fits correctly into the new pilot bearing. We have included two (2) different pilot bearings

with this new bellhousing kit. Select the proper bushing and install it into the engine crank. We recommend that you

trial fit the pilot bearing, input shaft and clutch assembly prior to installation into the vehicle. The clutch disc will be

1-1/8"-10 spline accept for the T150 3 speed transmissions that will require a 1-1/16"-10 clutch disc. If you are going

to use a slave cylinder for clutch control, the we recommend a high diaphragm clutch. If the original mechanical linkage

is going to be retained, then the clutch must be the high profile diaphragm type. Make sure that the arm has sufficient

clearance when extending back towards the transmission. Some conversions may require a slight bellhousing or clutch

arm modification. When using a zoom clutch pressure plate, the clutch housing is much higher than the normal Chevy

design. The only modification for zoom clutch applications would be to reduce the thickness of the flywheel. If you

are going to install this into a vehicle that has not previously equipped with the correct Jeep parts, then we have included

a list below of the necessary items:

(NOTE: THE CLUTCH FORK SPRING MAY NEED TO BE SHORTENED TO

KEEP TENSION BETWEEN CLUTCH FORK AND BALL PIVOT.)

If a 10-1/2" clutch with a 160 tooth flywheel is going to be used, make sure that a high diaphragm type clutch is installed

with the same N1714 release bearing.

DUST COVER INSTALLATION:

Currently we do not have a dust cover for this application and you will need to use one from a Buick application and

will need to modify it accordingly. If your engine is 1986 or newer and used the large rear main seal, you will need

to modify the inside diameter of the steel sheet metal plate to allow for clearance around the rear main seal area.

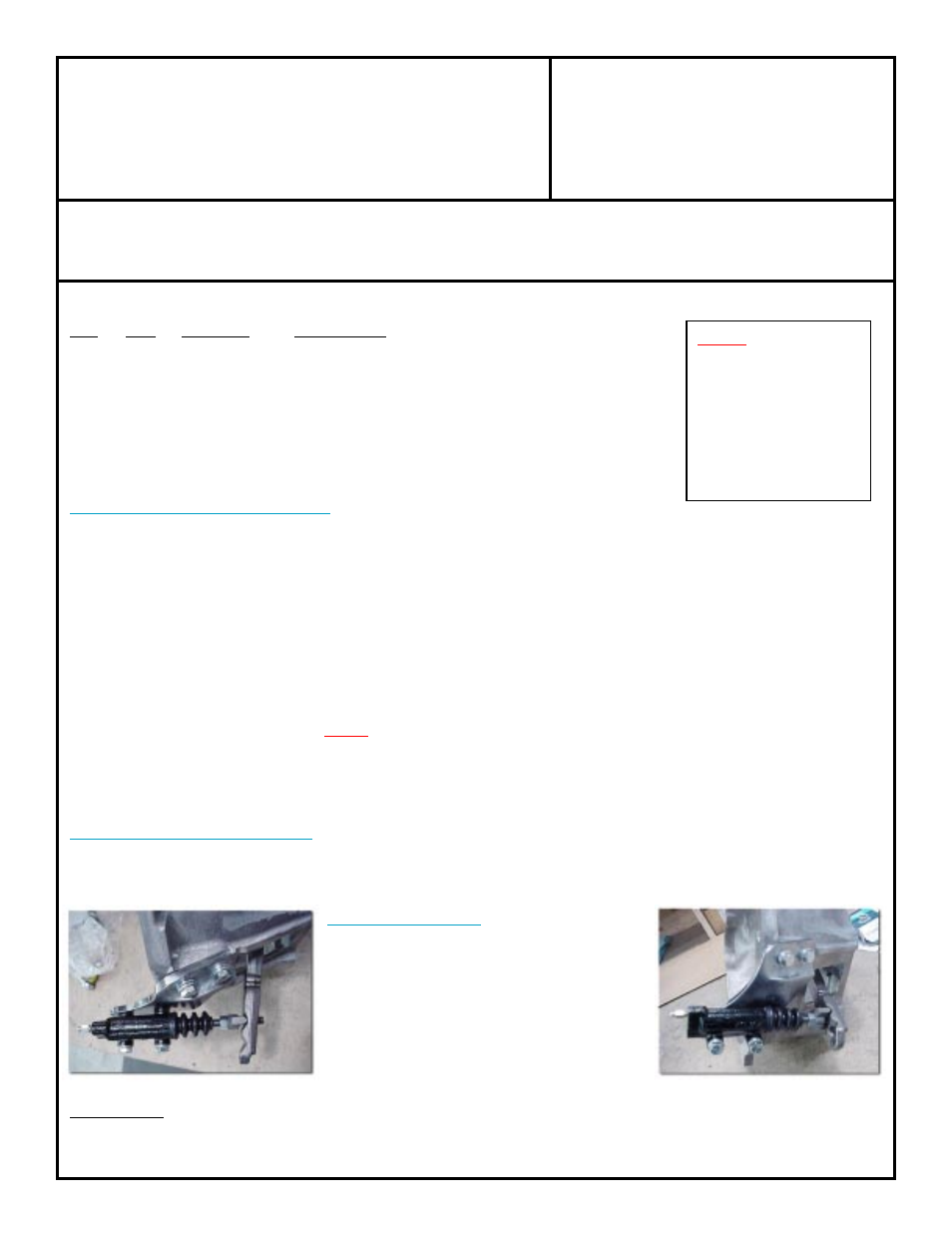

CLUTCH LINKAGE:

We do not offer and linkage brackets for the

bellhousing for either a hydraulic or mechanical

linkage. Two holes have been provided on the

side of the bellhousing for the mounting of a

fabricated bracket. These photos show a bracket

that was fabricated to fit a Toyota Land Cruiser

slave cylinder to this bellhousing.

NOTE:

Recommended N1714

throw out bearing due

to Jeep/Ford retainer

diameter & Chevy

throw out lever.

See Page 3 for recessed

flywheel information