Three-pulley (idler sheave) assembly, Maintenance, Warning – Aerovent IM-121 User Manual

Page 9

Aerovent IM-121

9

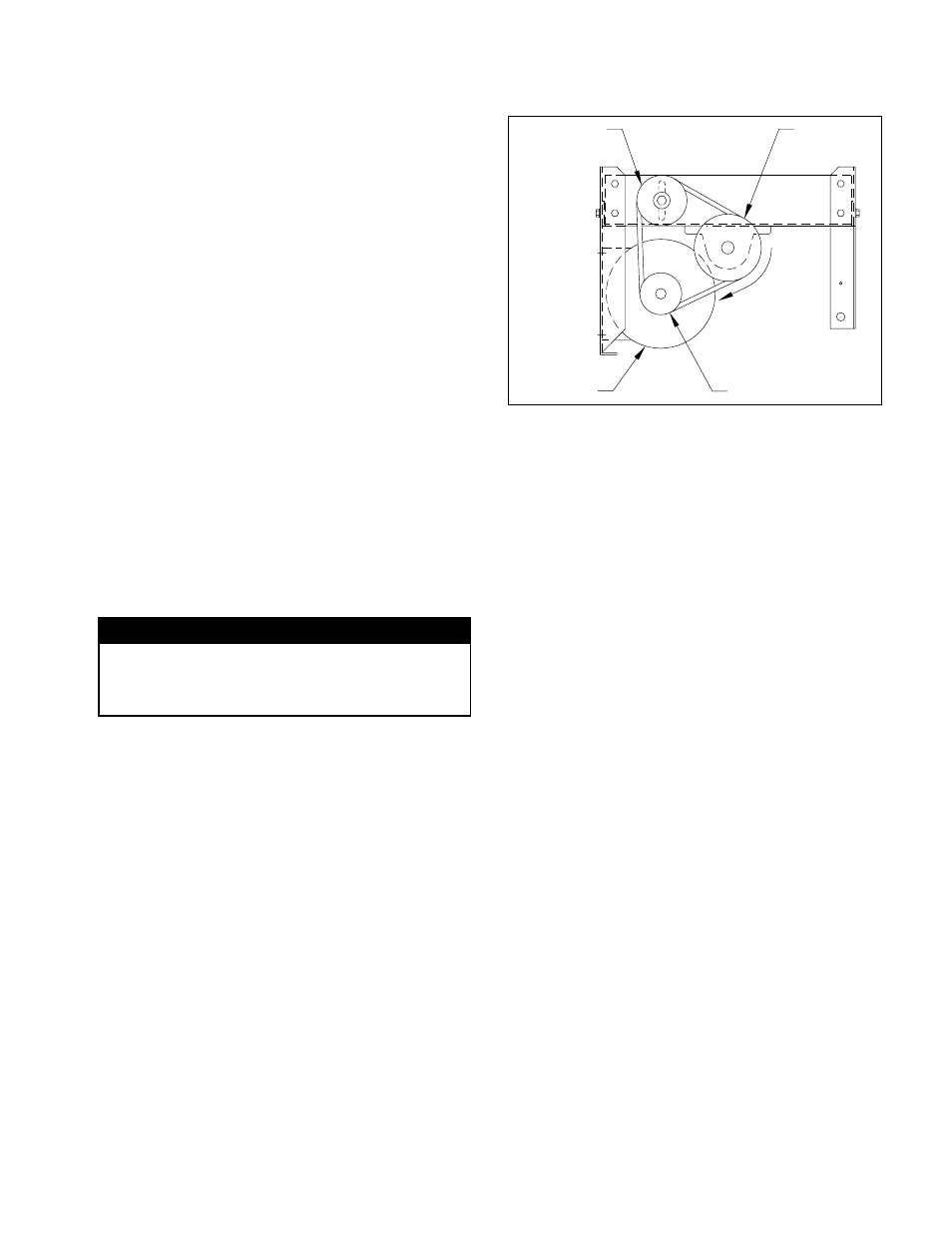

Three-Pulley (Idler Sheave) Assembly

Single bolt belt adjustment (Figure 9) can be made by

loosening the idler sheave bolt (with

3

/

4

" wrenches) and

moving it to the point where proper tension is achieved,

per Page 8, Figure 5. Alignment is necessary prior to

belt adjustment. See Figure 6.

This configuration is standard on ACX sizes 070-160

and ATB (family) sizes 110-180. All other adjustments

are made by moving the motor.

IDLER SHEAVE

FAN SHEAVE

MOTOR SHEAVE

MOTOR

Figure 9. Three-Pulley (Idler Sheave) Assembly

Maintenance

Installation and maintenance are to be performed only

by qualified personnel who are familiar with local codes

and regulations and experienced with this type of equip-

ment.

CAUTION: Sharp edges and screws are a potential injury

hazard. Avoid them.

WARNING

Hazardous moving parts. Unit may contain pro-

tected fan motor which may start automatically

and cause injury. Allow time for reset. Disconnect

power before servicing.

Preventive maintenance is the best way to avoid unnec-

essary expense and inconvenience. Start-up and routine

maintenance should cover the following items:

a. Tighten all setscrews, bolts and wire connections.

b. Check belt tension and sheaves for wear.

c. Lubricate fan bearings (see Tables 5 and 6).

d. Cleaning of unit, wheel and damper (if present).

All motors containing ball bearings are permanently

lubricated from the factory. No additional maintenance

is required.

1. Before performing any maintenance on the fan, be

sure power is turned off and locked in the OFF

position at the service entrance.

2. Ventilators should be carefully checked at least once

a year. For critical or rugged applications, a routine

check every two or three months is suggested.

3. All motors supplied with Aerovent ventilators carry

a one-year limited warranty from date of shipment.

For repairs within the warranty period, the motor

must be taken to the motor manufacturer’s autho-

rized service dealer. Contact your representative for

additional warranty details.

4. A periodic motor check should consist of spinning

the motor shaft with the power off to be sure the

motor turns freely and the bearings run smoothly.

The belt on belt driven units should be removed

from the motor sheave.

5. When removing or installing a belt, do not force

the belt over the sheave. Loosen the motor mount

so that the belt can be easily slipped over the

sheave.

6. The belt on belt driven units should be removed and

carefully checked for glazing, cracks, ply separation

or irregular wear. A small irregularity in the contact

surface of the belt will result in noisy operation. If

any of these defects are apparent, the belt should

be replaced. Check the sheaves also for chipping,

dents or rough surfaces which could damage the

belt.

7. The correct belt tension is important. Too tight of

a belt will result in excess bearing pressure on the

motor bearings and shaft pillow blocks and may

also overload the motor. Too loose of a belt will

result in slippage which will quickly “burn” out belts.

A belt should feel “live” when thumped, approxi-

mately

1

⁄

4

" belt deflection (3 to 5 lb.) when subject

to finger pressure at midpoint between sheaves.

8. The belt alignment should also be checked to be

sure the belt is running perpendicularly to the rotat-

ing shafts. Fan and motor shafts must be paral-

lel. Improper alignment will result in excessive belt

wear.

9. Check sheave setscrews to ensure tightness. Proper

keys must be in keyways.

10. Do not readjust fan RPM. If sheaves are replaced,

use only sheaves of identical size and type.

11. If unit is to be left idle for an extended period, it is

recommended that belts be removed and stored in

a cool, dry place to avoid premature belt failure.