Check, test & start procedure, Warning – Aerovent IM-121 User Manual

Page 6

6

Aerovent IM-121

Table 2. Wheel to Inlet Venturi

MODEL

GAP

OVERLAP

ACX 070/075

---

0.25

ACX*

---

0.50

ATB/ATBR/AWX/AWXR

0.06

---

ACXD

0.25

---

ATD/ATDR/ATDW/ATDWR

0.06

---

*all sizes except 070 and 075.

Check, Test & Start Procedure

WARNING

Electric shock hazard. Could cause severe injury or

death. Failure to bond the frame of this equipment

to the building electrical ground by use of the

grounding terminal provided or other acceptable

means may result in electrical shock. Disconnect

electric power before servicing equipment. Service

to be performed only by qualified personnel.

BEFORE START-UP: Disconnect power to this unit

before servicing the unit.

1. Check to verify that the wheel is free to rotate.

2. For optimum fan performance make sure that the

wheel to inlet venturi gap or overlap is maintainted.

See Table 2.

3. Verify that supply voltage on the line side of discon-

nect agrees with voltage on fan data plate and is

within the 10% utilization voltage.

4. Apply power to unit and check rotation of wheel with

the directional arrow on the unit. See Table 1.

WARNING: Rotation is critical. If allowed to operate

in the wrong direction, the motor will overload and

burn out.

WARNING: Especially check three-phase units for

rotation. For three-phase, rotation can be changed by

interchanging any two of the three line leads. If unit is

checked on temporary wiring, it should be rechecked

when permanently installed. Motor burn-out or tripped

overload protection devices are usually the result of

wrong rotation.

5.

Electrical Input Check: Perform check of fan ampere

draw and verify that motor nameplate amps are not

exceeded. Take into account the service factor range

if motor is nameplated above a 1.0 service factor.

6. Fan RPM should be checked and verified with a

tachometer.

7.

Units with Speed Control (Direct Drive): Verify that

speed controller gives desired operating range of

RPM. If minimum speed value is not desired, it may

be adjusted. See page 7.

NOTE: The fan should not need balancing, as it was

balanced at the factory to be within stringent vibration

levels before shipment. However, there are several

things that may cause vibration, such as rough han-

dling in shipment and installation, weak foundations

and alignments.

Table 1. Wheel Rotation*

MODEL

CW

CCW

ACX

all other

070, 075

ATB/ATBR/AWX/AWXR

all other

160, 180

ACXD

---

all

ATD/ATDR/ATDW/ATDWR

---

all

* Wheel rotation is determined when viewed from top of fan

(opposite air intake).

Note: On fans with three phase motors the wheel rotation can

be changed by reversing any two power leads.

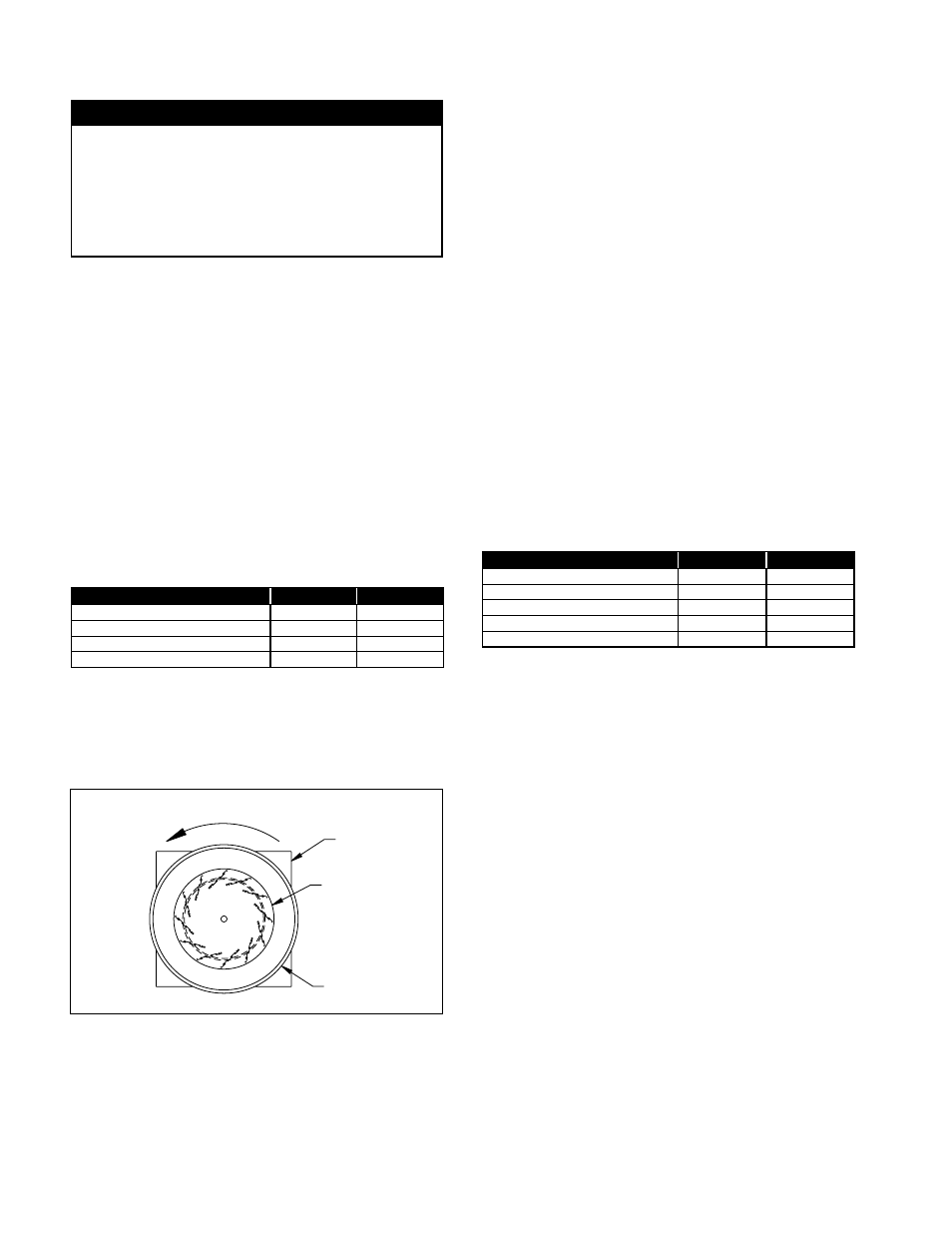

Figure 1. Fan Wheel Rotation - View from Exhaust End

WHE

EL ROTATIO

N

CURB

BASE

FAN

WHEEL

HOUSING

Note: CCW rotation shown, CW rotation is similar but opposite.