V-belts – Aerovent IM-121 User Manual

Page 8

8

Aerovent IM-121

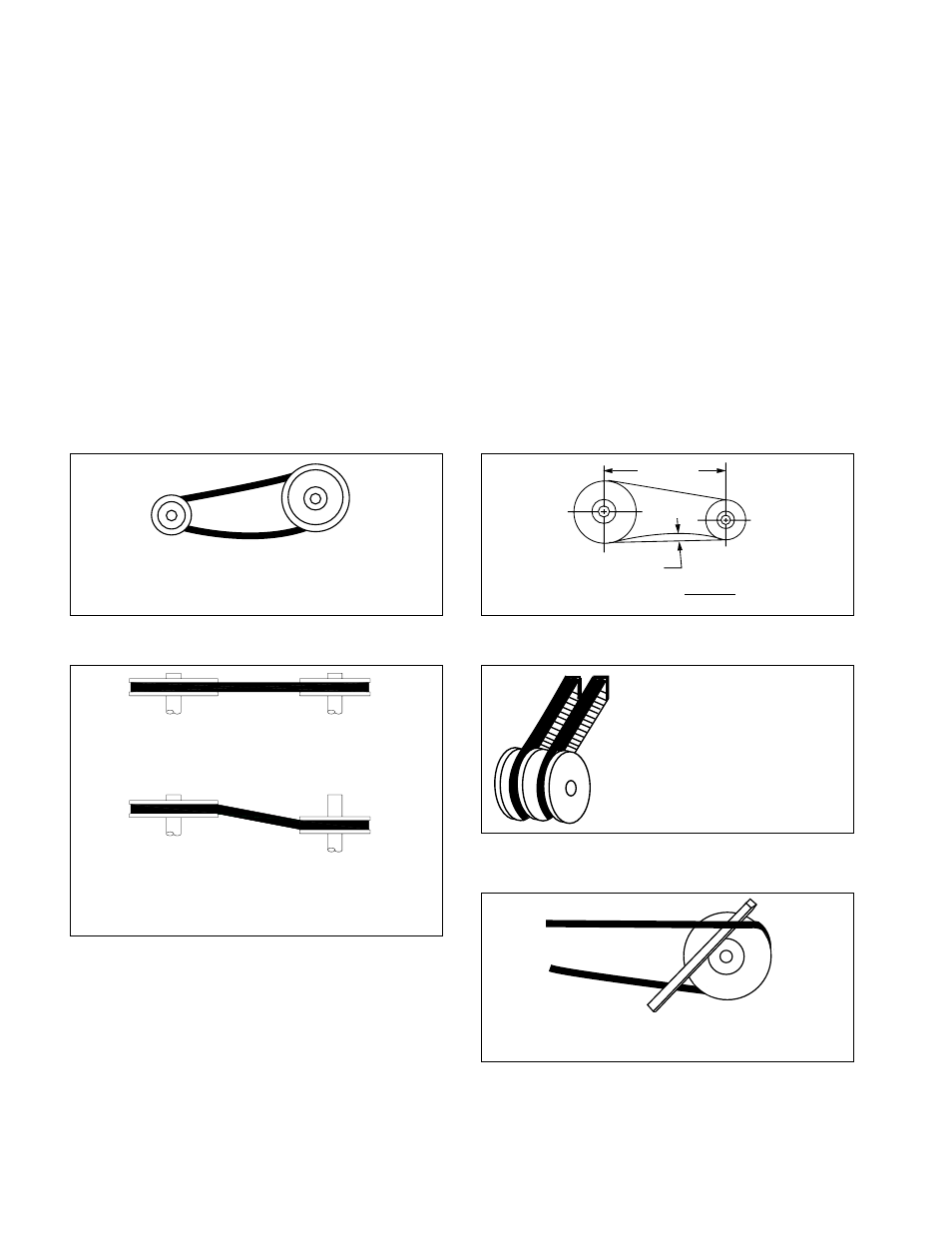

Figure 4. Eliminate Slack

Figure 5. Belt Deflection

Figure 6. Alignment

Figure 7. Two-Groove Sheaves (Pulleys)

Figure 8. Belts

Deflection

Deflection =

Belt Span

64

Belt Span

Slack belts wear excessively, cause slippage

and deliver less power. For longest belt life,

always provide proper tension

Mount belts straight. Shafts must be parallel

and sheaves in alignment to prevent unnec-

essary belt wear.

Two-groove variable pitch

sheaves must be opened the

same number of turns on

both sides; otherwise, slip-

page occurs, wearing belts

rapidly.

Do not force belt. Forcing the belt will

break the cords and cause belt failure.

V-Belts

V-belts on these belt driven fans are oil, heat, and static

resistant type and oversized for continuous duty. With

proper installation and maintenance, years of operating

efficiency can be added to the lifespan of the V-belt

drive.

The condition of V-belts and the amount of belt ten-

sion should be checked prior to start-up (see Figure

4). When it becomes necessary to adjust belt tension,

do not over-tension as bearing damage will occur.

Recommended belt tension should permit

1

⁄

64

" deflection

per inch of span of the belt at the center of the belt

span. To find this point, measure halfway between the

pulley centerlines as shown in Figure 5. Extreme care

must be exercised when adjusting V-belts as not to mis-

align the pulleys. Any misalignment will cause a sharp

reduction in belt life and will also produce squeaky,

annoying noises (see Figure 6). On units equipped with 2

groove pulleys, adjustments must be made so that there

is equal tension on all belts (see Figure 7).

1. Where tensioning rods are not provided, adjustment is

more easily obtained by loosening and adjusting one

side of the motor bracket at a time.

2. Always loosen tension adjustment enough to place

belts on sheaves without running belts over the edge

of either sheave. A new belt may be seriously dam-

aged internally by careless handling (see Figure 8).

WARNING: When removing or installing belts, never force

belts over pulleys without loosening motor first to relieve

belt tension. The fan has been checked for mechanical

noises at the factory prior to shipment. If mechanical

noise should develop, then some suggestions are offered

here as a guide toward remedying the cause.

1. Check rotating members for adequate clearance.

2. Check proper belt tension and pulley alignment.

3. Check installation and anchoring.

4. Check fan bearings.

CORRECT

INCORRECT