Snorkel AB80J User Manual

Page 69

Chapter 11 – Troubleshooting

AB80J/AB85J – 0420453

65

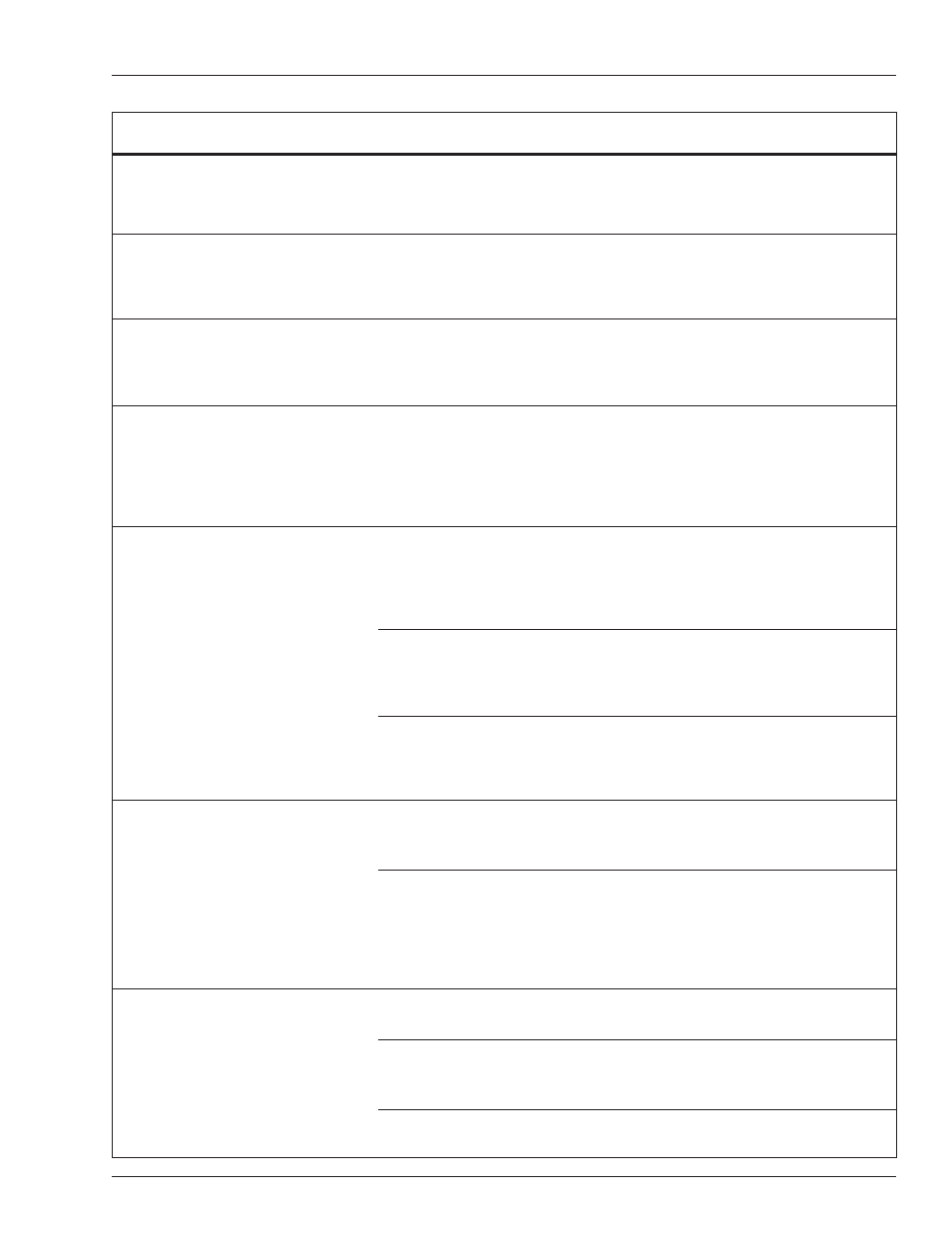

Symptom

Engine will not start from

upper controls.

Engine starts from the upper

controls but no boom functions

work – machines with AC gen-

erator option only.

Engine dies when the control

selector switch at the lower

controls is placed in the upper

control position.

After starting the engine, it will

not throttle up and dies when a

function is operated – GM 2.4

engines only.

Constant tone alarm sounds

while the engine is running.

Constant tone alarm sounds

and engine shuts off.

All functions stop working.

Continued on next page...

Possible Cause

The main system circuit breaker on

the lower or upper control panel has

tripped. The engine will not crank.

The machine/generator switch is in

the generator position.

Upper controls are not set-up properly.

Function is operated within a few

seconds after starting the engine.

High engine temperature.

Low oil pressure.

No alternator current/broken fan

belt.

High engine temperature.

Low oil pressure.

Low fluid level in reservoir.

Engine or pump failure.

Circuit breaker is tripped.

Corrective Action

Push the main system circuit breaker

button back in. If the button pops

back out, refer the problem to a quali-

fied service technician.

Place the switch in the machine posi-

tion to operate machine functions.

At the upper controls, pull the emer-

gency stop button upward and turn

the anti-restart master switch on.

Normal operation for GM 2.4 engine.

There is a 7 to 10 second delay after

each engine start before the throttle

will go to mid or high to prevent an

engine overspeed under certain start-

ing conditions.

Lower the platform and reduce the

engine speed to idle for five minutes.

Turn the engine off and let it cool. Do

not restart the engine until the cause

of overheating has been corrected.

Lower the platform and turn the

engine off. Do not restart the engine

until the cause of low oil pressure has

been corrected.

Turn the engine off. Do not restart the

engine until the cause of no alternator

current has been corrected or the fan

belt is replaced.

Let the engine cool. Do not restart the

engine until the cause of overheating

has been corrected.

Do not restart the engine until the

cause of low oil pressure has been

corrected. The engine can be re-

started with low oil pressure, but it

will only run a few seconds before it

shuts off again.

Check fluid level. Add correct type of

fluid if necessary.

Manually stow the machine using

the emergency power system or the

emergency lowering knob.

Push circuit breaker button in to

reset.