Routine service, Routine service table key, Service report – Snorkel SL30N-sn9600-11199CE User Manual

Page 8: Every year or 500 hours 2

8

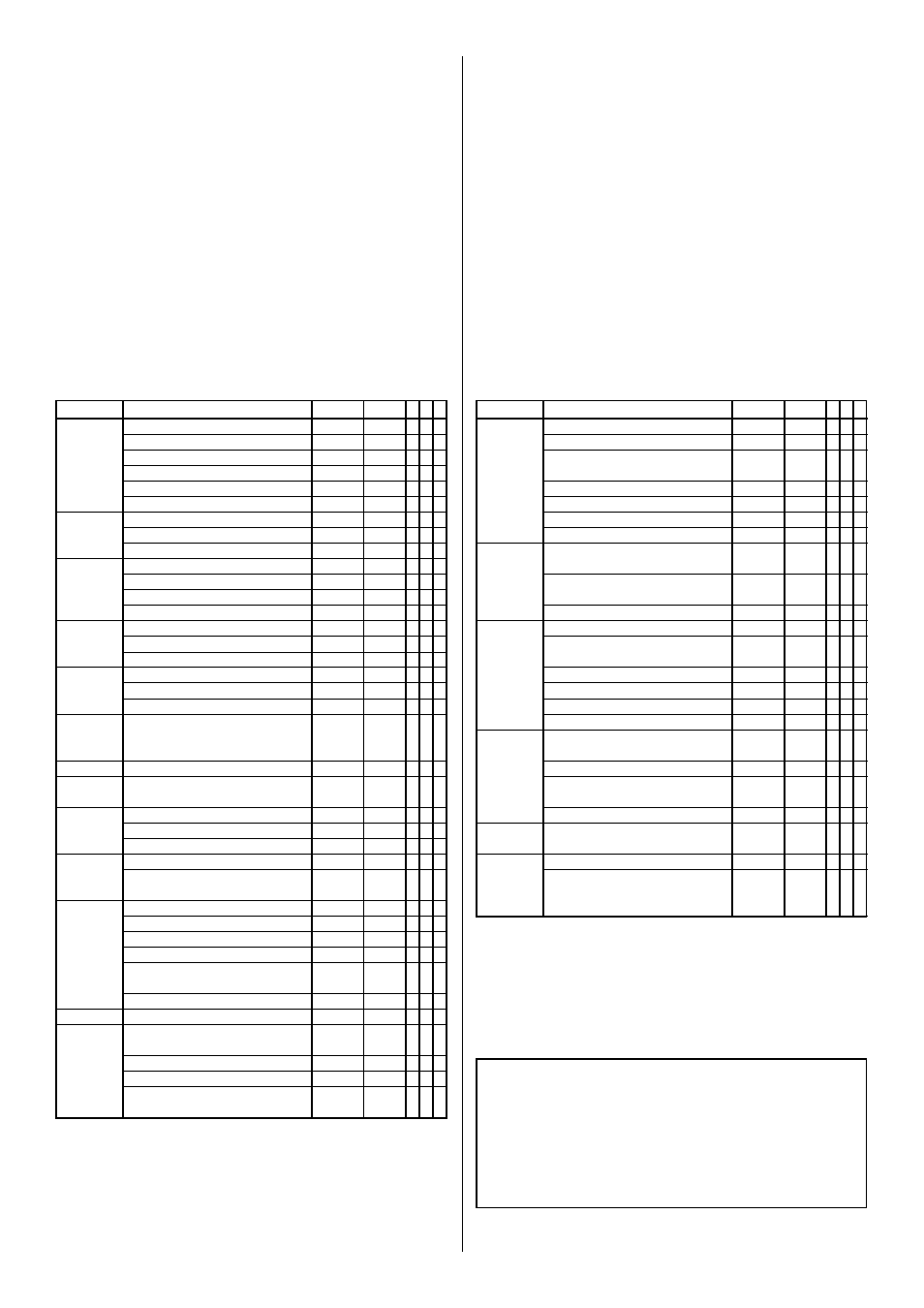

Routine Service Table Key

Interval

Daily=each shift (every day) or every eight hours

30

D

=every month (30 days) or every 50 hours

3

M

=every 3 months or 125 hours

6

M

=every 6 months or 250 hours

1

Y

=every year or 500 hours

2

Y

=every year or 1000 hours

Model

A= All Models

E= Electric Models

D= Dual Fuel Models

Y=Yes/Acceptable

N=No/Not Acceptable

R=Repaired/Acceptable

Routine Service

Use the following table as a guide for routine

maintenance. Inspection and maintenance shall

be performed by personnel who are trained and

familiar with mechanical and electrical proce-

dures. Refer to the Service Manual for complete

service instructions.

Please copy the following page and use the Rou-

tine Service table as a checklist when inspecting a

machine for service.

COMPONENT INSPECTION OR SERVICES

INTERVAL MODEL Y N R

Battery

Check electrolyte level

Daily

A

System

Check specific gravity

30

D

A

Clean exterior

6

M

A

Check battery cable condition

Daily

A

Charge batteries

Daily

E

Clean terminals

6

M

A

Engine Oil

Check level and condition

Daily

D

Check for leaks

Daily

D

Change oil filter

30

D

D

Engine Fuel Check fuel level

Daily

D

System

Check for leaks

Daily

D

Replace fuel filter

6

M

D

Check air cleaner

Daily

D

Hydraulic Oil Check oil level

Daily

A

Change filter

6

M

A

Drain and replace oil

2

Y

A

Hydraulic

Check for leaks

Daily

A

System

Check hose connections

30

D

A

Check hoses for exterior wear

30

D

A

Emergency

Open the emergency lowering

Daily

A

Hydraulic

valve and check for

System

serviceability

Controller

Check switch operation

Daily

A

Control

Check the exterior of the cable

Daily

A

Cable

for pinching, binding or wear

Platform

Check fasteners for proper torque

Daily

A

Deck and

Check welds for cracks

Daily

A

Rails

Check condition of deck

Daily

A

Tyres

Check for damage

Daily

A

Check lug nuts/bolts,

30

D

A

torque to 123 Nm (90 ft. lbs.)

Hydraulic

Wipe clean

30

D

A

Pump

Check for leaks at mating surfaces

30

D

A

Check for hose fitting leaks

Daily

A

Check mounting bolts for proper torque

30

D

A

Check the drive coupling for proper

torque and alignment

1

Y

A

Lubricate pump splines

6

M

D

Drive Motors Check for operation and leaks

Daily

A

Steering

Check hardware & fittings

6

M

A

System

for proper torque

Grease pivot pins

30

D

A

Oil king pins

30

D

A

Check steering cylinder for leaks &

30

D

A

mounting bolts for proper torque

COMPONENT INSPECTION OR SERVICES

INTERVAL MODEL Y N R

Elevating

Inspect for structural cracks

Daily

A

Assembly

Check pivot points for wear

30

D

A

Check mounting pin pivot bolts

30

D

A

for proper torque

Check linkage gear for wear

6

M

A

Check elevating arms for bending

6

M

A

Grease linkage pins

30

D

A

Grease linkage gear

30

D

A

Chassis

Check hoses for pinch or

Daily

A

rubbing points

Check component mounting

6

M

A

for proper torque

Check welds for cracks

Daily

A

Lift

Check the cylinder rod for wear

30

D

A

Cylinder

Check mounting pin pivot bolts

30

D

A

for proper torque

Check pivot pin snap rings

30

D

A

Check seals for leaks

30

D

A

Inspect pivot points for wear

30

D

A

Check fittings for proper torque

30

D

A

Entire

Check for and repair

Daily

A

Unit

collision damage

Check fasteners for proper torque

3

M

A

Check for corrosion-remove

6

M

A

and repaint

Lubricate

30

D

A

Labels

Check for peeling, missing, or

Daily

A

unreadable labels & replace

Wheel

Check wheel assembly for play

30

D

A

Bearings

Repack wheel bearings

2

Y

A

(replace wheel bearings and

seals at 2000 hrs.)

Service Report

Date: ______________

Owner: ________________________________

Model No: ____________ Serial No: _________

Serviced By: ____________________________

Service Interval: _________________________