AEM 30-6101 Series 2 Plug & Play EMS User Manual

Page 7

Page 7 of 13

This product is legal in California for racing vehicles only and should never be used on public highways.

Primary Load Sensor

AEM recommends installing an aftermarket MAP sensor for vehicles that will be turbocharged,

please see the wiring diagram on page 3 and use the startup calibration that includes ‘AEM

3.5Bar MAP’ in the filename.

The frequency-type Volume Airflow Meter found on 1993-1995 vehicles is not supported. If the

vehicle will remain naturally aspirated, please use the startup calibration that includes ‘Alpha-

N’ in the filename. The Alpha-N calibration uses the throttle position sensor for the main load

input on the fuel map. Using the throttle sensor for load is not ideal for idle quality or drivability,

but it tends to work well for naturally aspirated racecars that utilize aggressive cams.

For 1996-1997 vehicles, the Toyota hot-wire Mass Air Flow (MAF) sensor is used as the load

input in the

startup calibration that includes ‘MAF’ in the filename. The channel ‘MAF as Load’

must be used to view engine load and the ‘Fuel MAF’ table must be used to adjust fueling.

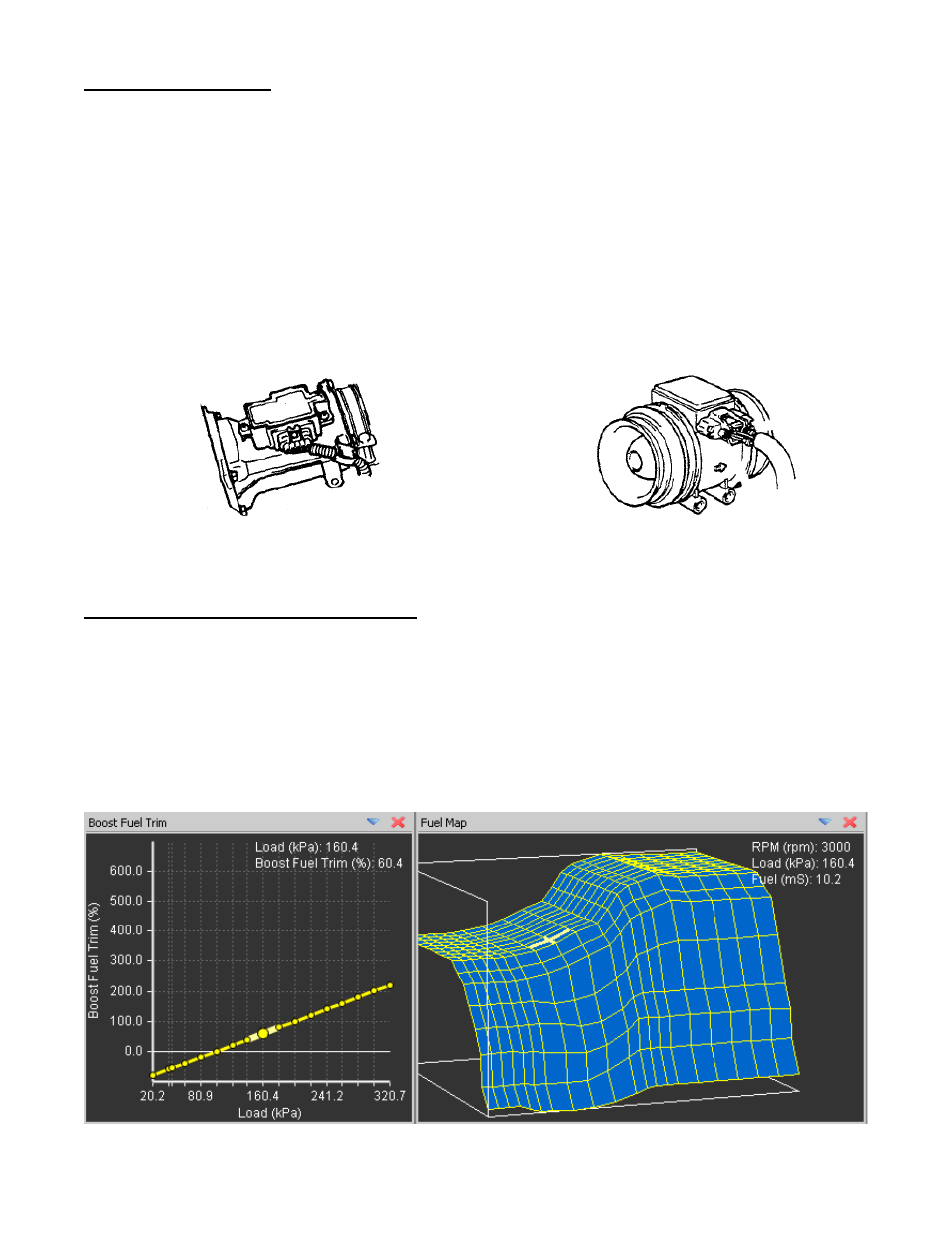

Frequency-type Airflow Meter (1993-1995)

Hot-wire MAF (1996-1997)

EMS Fuel Map, Boost Fuel Trim Table

The 30-6101 MAP calibration provided utilizes the

“Boost Fuel Trim Table” to provide a 1:1 fuel

compensation above and below atmospheric pressure. In the startup calibration, the “Boost

Fuel Trim Table

” is configured to provide twice as much fuel when the manifold pressure is

twice as high; this should help simplify the tuning process for different boost levels. Notice the

values in the main

“Fuel Map” do not change significantly above 100 kPa (0 psi boost), the fuel

correction is being made by the

“Boost Fuel Trim Table.” Note: the “Boost Fuel Trim Table”

must be adjusted if a different map sensor is installed or if the Load breakpoints are adjusted.

The Boost Fuel Correct value should be set to -75 at 25kPa, 0 at 100 kPa, +100 at 200 kPa,

+200 at 300 kPa, etc…