Servicing instructions – L.B. White Pilot User Manual

Page 72

Equipment R

Required:

Certified Leak Detectors

1 - 3/16 Hex Head Allen Key

2 - Low Pressure Gauge Kits,

Part Number 550-00764

ATTENTION

This procedure is to be done once a year prior to the heating

season, any time the appliance is moved from one location

to the other, or after servicing the heater.

ATTENTION

■

The following explains a typical procedure to be followed

in checking gas pressures on control valves.

■

The gas pressures will vary depending upon heater

model and fuel type.

■

Consult the dataplate or the heater specification on

pages 4 and 5 in this guide for specific pressures to be

used in conjunction with this procedure.

■

Gas pressure measured at the inlet to the gas valve is

Inlet Pressure and gas pressure measured at the outlet

of the gas valve is Burner Manifold Pressure.

A. Preparation

1. Make sure all threaded connections to the inlet of the

control valve are tightened securely. Obtain two

pressure gauges capable of reading up to 35 in. W.C.

2. Disconnect the heater from the electrical supply and

close the fuel supply valve to the heater inlet.

3. Open or remove the burner access panel. Remove the

protective cover from over the control valve, if

applicable.

4. Brush or blow off any dust or dirt on or in the vicinity

of the gas control valve.

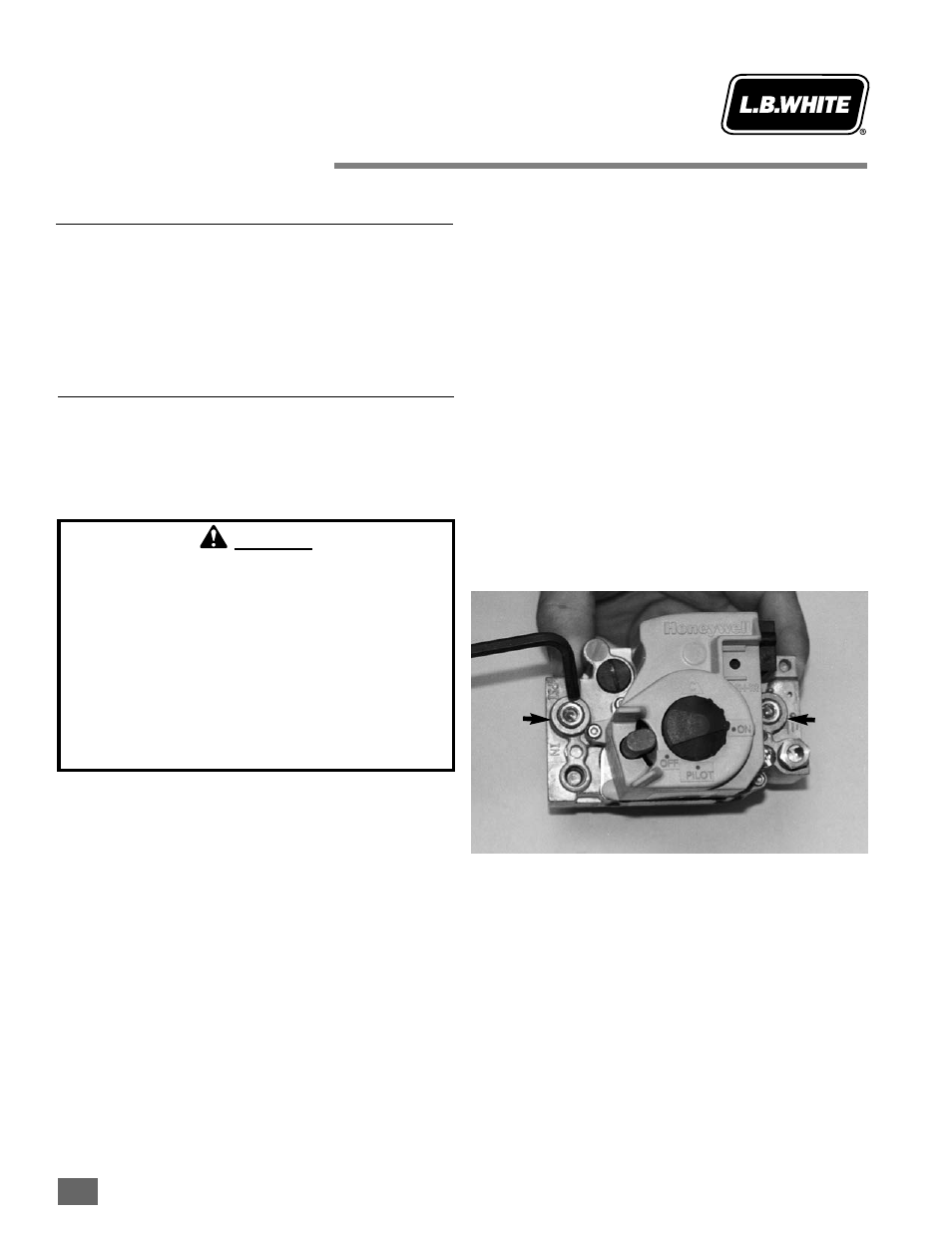

B. Gauge IInstallation

1. Locate the inlet and outlet pressure taps.

2. Using a 3/16 in. allen key, remove the taps at the inlet

and outlet of the control valve and install a threaded

gauge adapter and a low pressure gauge at these

points. Since some heaters used control valves from

different manufacturers, the location of the pressure

taps may vary slightly.

Leak and Gas Pressure Checks

Servicing

Instructions

WARNING

Fire aand EExplosion H

Hazard

■

Do not disassemble the gas control valve.

■

Do not attempt to replace any components on the

gas control valve.

■

The gas control valve must be replaced if any physical

damage occurs to the control valve assembly.

■

Failure to follow this warning will result in fire or

explosions, leading to injury or death to humans and

livestock, and building damage.

August 1999

8.9-1

1

Inlet

Pressure

Tap

Outlet

Pressure

Tap