Installation instructions – L.B. White Pilot User Manual

Page 14

A

B

C

D

E

F

G

H

300'

40'

20'

50'

50'

50'

30'

30'

50'

20'

50'

2.2-1

1

August 1999

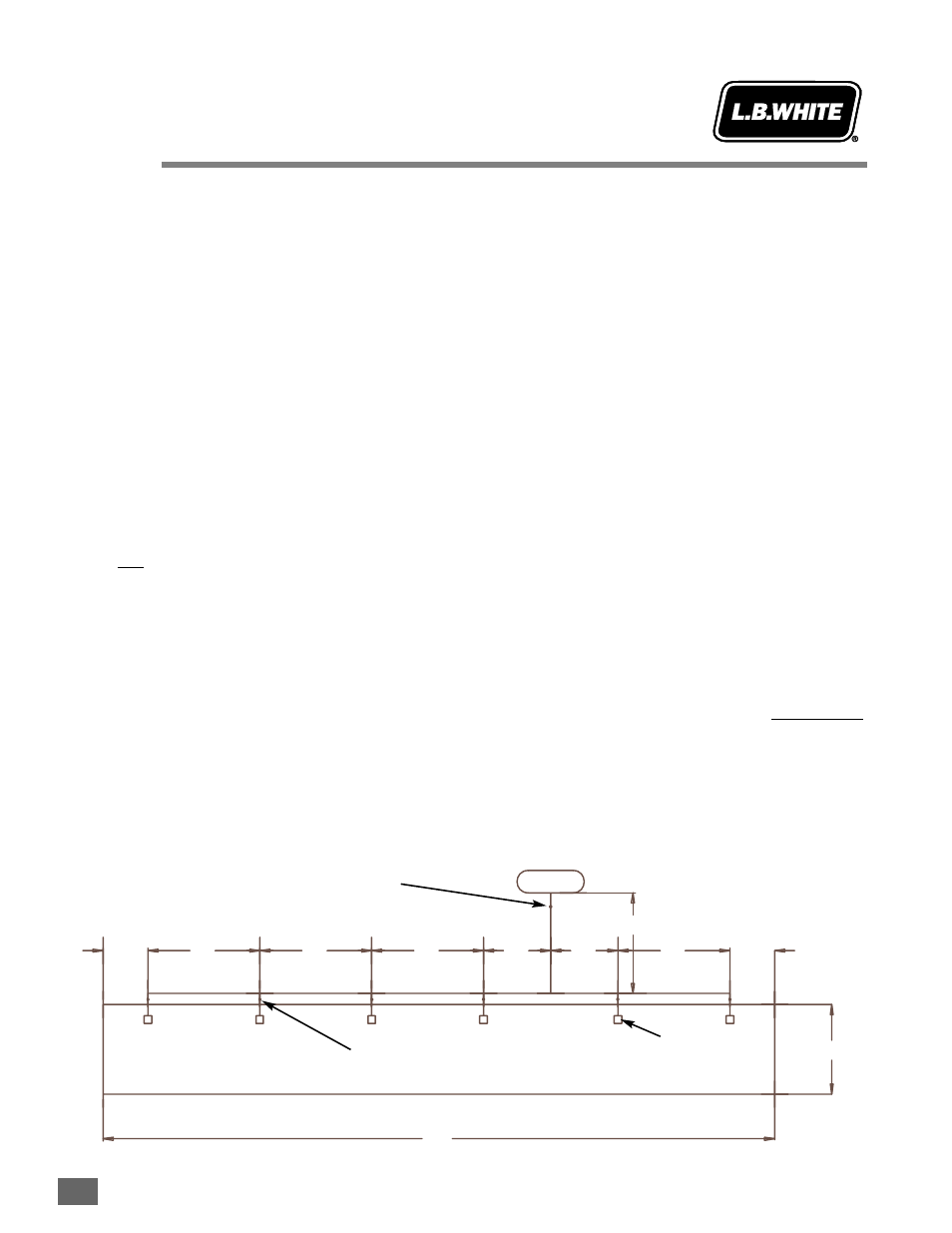

Fig. 1

LP Tank

First Stage Regulator (Tank Pressure Reduced to 5 psig)

Second Stage Regulator, 5 psig Inlet

Heater

GENERAL IINFORMATION

Pipe sizing is critical to the proper operation of any gas

heating system. However, piping is dependent on several

factors:

1. Total gas load expressed in BTUH.

2. The gas pressure to be supplied through the piping

system. This pressure may be expressed in pounds of

pressure per square inch (psi) or inches of water

column (W.C.).

3. Distance that the gas must travel to feed the heater

furthest from the regulator.

This section provides a basic explanation of how to size

piping for the heaters through the use of pipe sizing tables

and a typical example. In all cases with this example, we will

be using only pounds of pressure, expressed as 5 psi and not

inches of water column.

a. Black iron pipe only was used in this example as it is

less expensive per foot than copper tubing and,

therefore, more commonly used. However, the same

selection process using copper tubing may be done if

so desired. Refer to appropriate pipe sizing tables for

copper tubing. All pipe diameters given are measured

in inner diameter (I.D.). Piping planning and

installation must be done by an experienced, qualified

LP gas installation agency.

b. The minimum pipe size normally used in many

situations is 1/2 in. nominal.

c. The information in the pipe sizing tables was obtained

from Engineered Control International, Inc., L.P. Gas

Serviceman’s Manual L545.

d. Do not attempt gas supply line selection or installation

unless you are properly trained and qualified.

e. All gas supply lines must be leak checked after

installation and when pressurized to provide a safe

installation. Use only certified, approved leak

detectors.

f. This is one example showing how to size piping for a

building. Installation layouts differ as do the

pressures being supplied to piping, whether you are

using for LP gas or natural gas and the material (pipe

or copper tubing) being used.

INSTRUCTIONS

a. Determine total gas demand for entire system, by

adding up BTUH input from heater dataplates and

adding demand for any other gas-fired appliances and

any future heaters.

b. Measure the length of piping required from outlet of

first-stage regulator to the appliance furthest away.

No other length is necessary to do the sizing. In this

example the distance from first-stage regulator to

appliance furthest away is 230 ft.

c. Make a sketch of the piping system and installation.

See Fig. 1.

Pipe Sizing

Installation

Instructions