Servicing instructions – L.B. White Pilot User Manual

Page 65

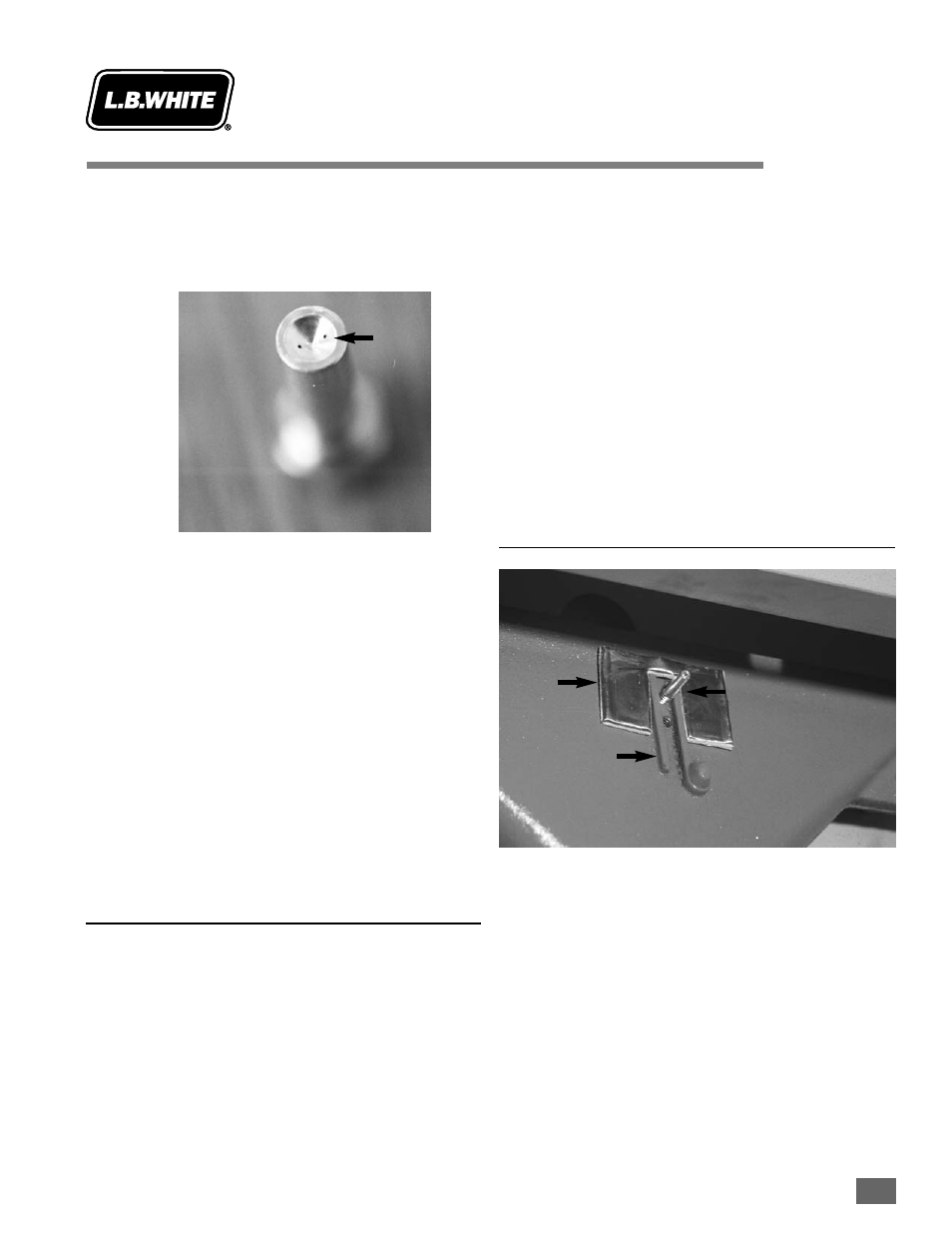

6. Pilot orifices may incorporate one or two holes,

depending on design. Hold the orifice up to light to

make sure the orifice is clear of blockages.

7. If the orifice is plugged, blow out the orifice with

compressed air or replace the pilot orifice if the

blockage cannot be removed.

IMPORTANT

■

The hole(s) in the pilot orifice are drilled to a

specific size to match the fuel and gas pressure.

■

Do not poke or push sharp instruments into the

orifice hole(s). This may create pilot light outages

or sooting.

■

Do not use a pliers to remove the pilot orifice.

Pliers will round off the hex nut on the base of

orifice, creating difficulty in servicing later. Use

only the appropriate size wrench.

■

Do not “kink” the pilot line when servicing. Doing

so may reduce gas flow to the pilot orifice

resulting in pilot outages.

8. Reverse these procedures to reinstall the orifice, pilot

line and shield.

ATTENTION

For H

Heaters sso EEquipped:

■

Use care when servicing the pilot assembly to

prevent damage to the pilot gasket.

■

Make sure the pilot gasket is properly positioned

around the two vertical ribs on the face of the

burner before reassembly. Failure to properly

install the gasket will result in pilot outages.

■

Use the pilot assemblies’ threaded stud to assist

in holding the pilot in position during reassembly.

Pilot Assembly

Servicing

Instructions

August 1999

8.5-2

2

Holes

Gasket

Burner R

Ribs

Stud