Fitting procedure winch – ARB 3415010 User Manual

Page 14

Last Rev Date:29/10/2008

Page 14 of 20

Fitting instructions# 3783250

Copyright © 2005 by ARB Corporation Limited. All rights reserved, this document must not be reproduced without the express authority of ARB Corporation Ltd

FITTING PROCEDURE WINCH

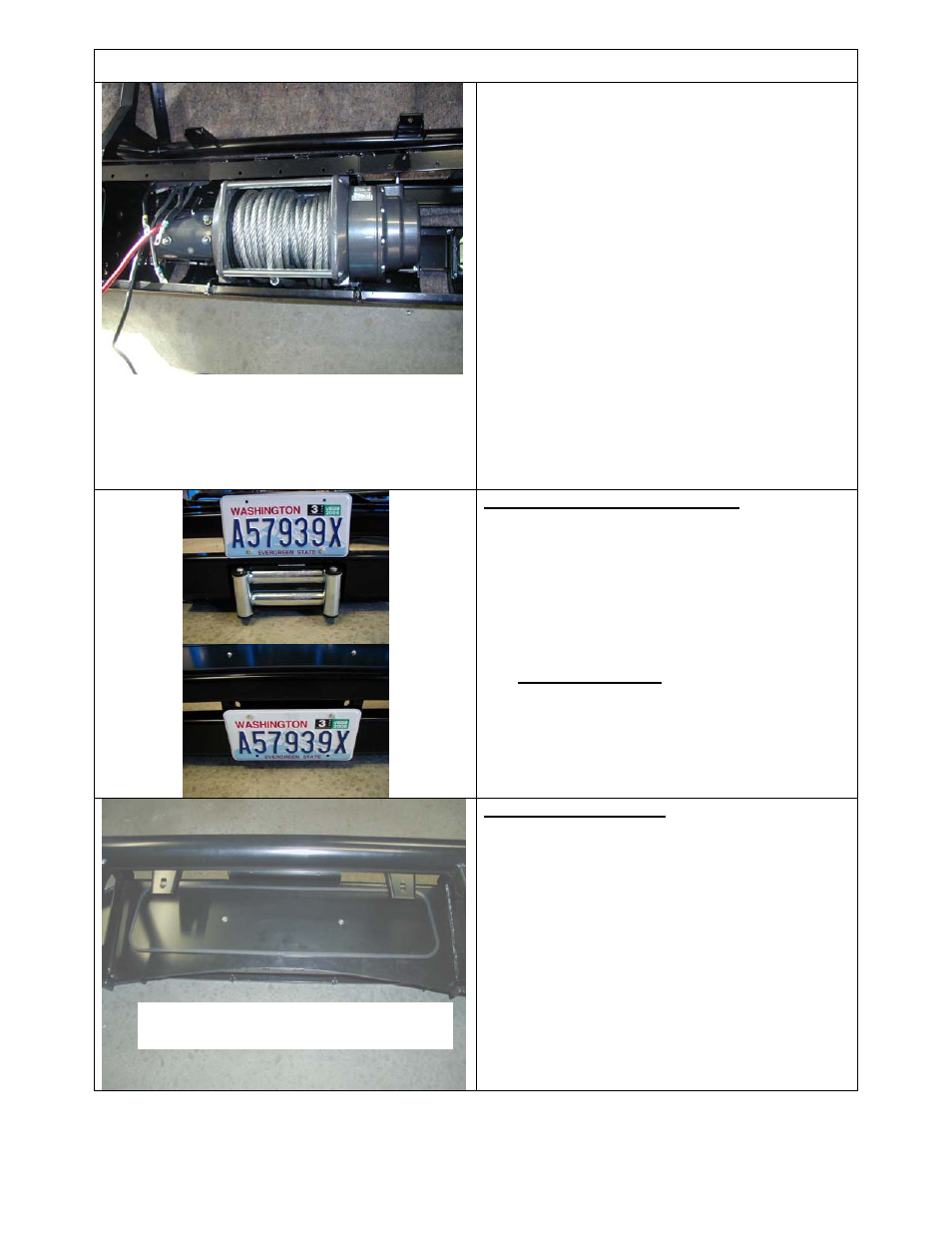

47. Viewed from front of vehicle the winch clutch

(handle) must be positioned on the LH side

(same side as smaller square access hole in

pan). Cable must spool from the bottom of

winch. Draw off enough cable so cable crimp

can be pulled through roller fairlead.

48. Bolt winch in position with the roller fair lead

in place.

Hint: To increase access to mount bolts in front of

roller fairlead, remove circlips from bottom of each

vertical roller shaft, push shaft up so roller can be

dislodged sideways. Do up bolts in fairlead and

winch, then refit circlip.

49. Connect the winch control box cables to the

winch motor. Refer to the Warn handbook for

additional information. Connect the long

winch + & - cables to the vehicle after the bar

is installed. Refer to the Warn winch

manual for vehicle wiring instructions.

Fitting number plate – with winch

50. Bolt number plate to the bracket with the M6 X

16mm bolts and M6 flange nuts through the

lower holes of the number plate.

If not fitting winch.

51. Bolt the number plate through the top holes

using M6 X 16mm bolts and M6 flange nuts.

If not fitting winch cont.

52. Wrap rubber extrusion around winch cover, trim

to length.

53. Place M6 flat washers over holes in the top

face of the bull bar where the winch cover is

fixed to the bull bar.

NOTE: The M6 washers support the cover and

prevent dipping around the screw heads.

54. Place the winch cover in position as shown with

screws aligning through the mount holes and

leaving the washers in place.

55. Bolt together using the M6 button head

stainless steel screws and M6 nuts.

View from above, rear of bull bar