Emi-automatic, Riming, Alve – Hale SPV User Manual

Page 8

S

emi-Automatic

P

riming

V

alve

6

Retrofit Installation:

When installing the Hale SPV as a retrofit on

a midship fire pump the following

procedures shall be followed. (Refer to

figure 5)

1. Place the apparatus out of service in

accordance with departmental

procedures. Drain all water from pump

b o d y .

WARNING: Disconnect or turn-off master

battery switch prior to service of the

Hale SPV electrical components. Make

sure there is no power at the primer

solenoid before starting service

procedures.

2. Open the pump operator panel and

gain access to the existing Hale PVG.

3. Disconnect the electrical leads and

vacuum hoses to the Hale PVG.

4. If the Hale PVG is mounted at the

operator panel, remove the Hale PVG

and placard.

5. Install the panel placard and

momentary contact push-button

provided with the Hale SPV on the

operator panel.

NOTE: A spacer is required where the

Hale PVG was removed to allow

mounting of the push-button switch.

Manufacture a spacer using the

template in figure 4 as a guide. The

outer surface of the spacer must be flat

to allow proper installation of the panel

placard push-button switch. Use

material thickness and fastening devices

that leave a flat surface.

6. Connect electrical leads to the

momentary contact push-button.

7. Locate the priming valve flange on the

midship pump. (Refer to figure 5) The

priming valve flange is located next to

the gearbox on the midship pump.

8. Remove the

7

/

16

-14 x 1-

1

/

4

inch long cap

screws that hold the priming flange,

hose and fittings on the midship pump

body. Remove the flange assembly

from the pump body.

9. Remove the strainer and seal ring from

the pump body. Clean the strainer of all

debris. DO NOT discard the strainer as it

must be used with the Hale SPV.

10. Apply a light coat of thread locking

compound (Loctite #290 or equal) to

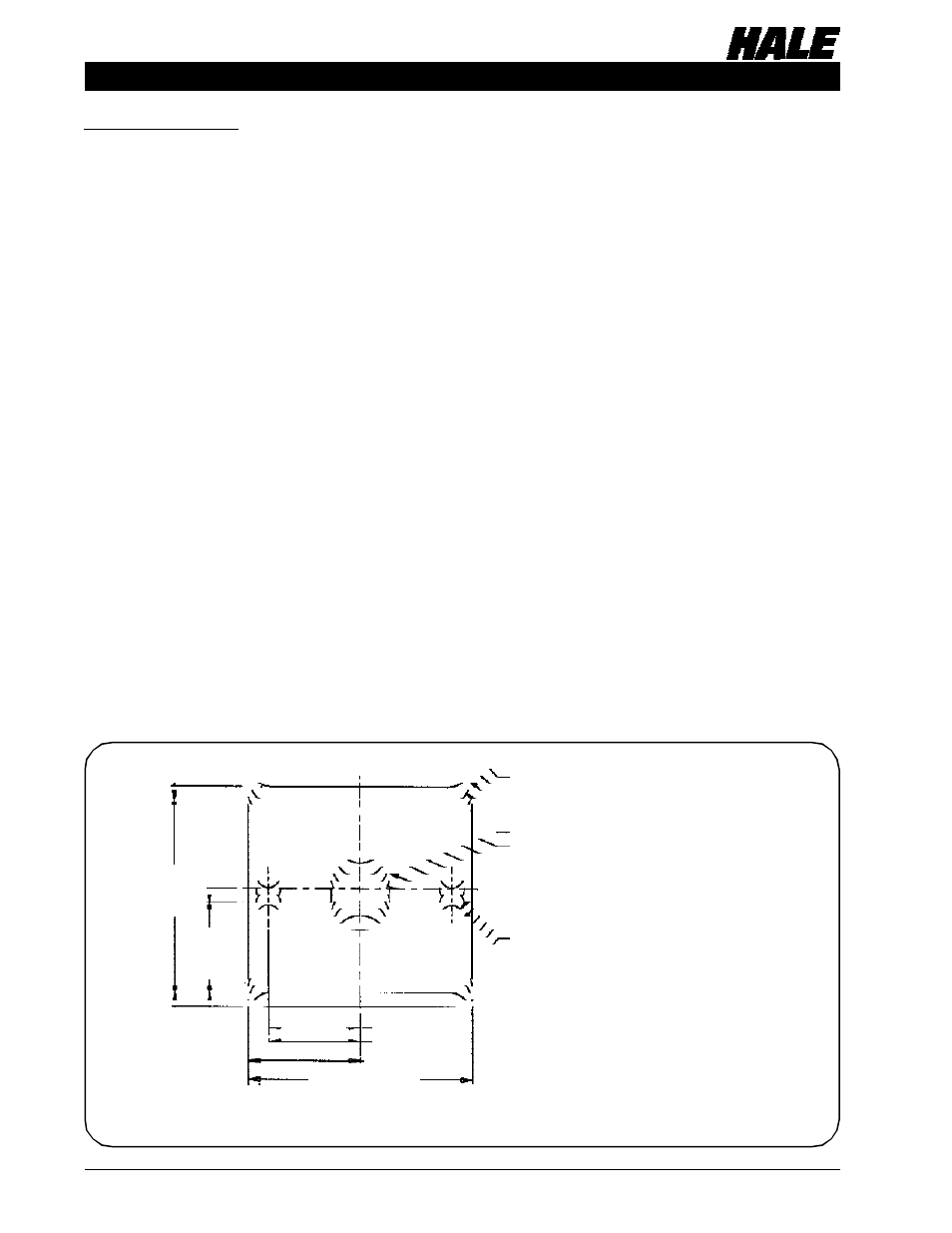

Figure 4. Panel Placard Spacer

0.64 IN. (16 mm)

THRU HOLE

2.32 IN.

(59 mm)

1.16 IN.

(29 mm)

0.25 IN. (6 mm)

RAD TYP

(2) THRU HOLES FOR

SPACER FASTENERS

2.44 IN. (62 mm)

1.22 IN. (31 mm)

1 IN. (25 mm)

NOTE: MATERIAL THICKNESS AND SPACER

FASTENERS MUST ALLOW FOR A FLAT SURFACE

WHEN THIS SPACER IS MOUNTED ON THE

OPERATOR PANEL. USE COUNTERSUNK

FLATHEAD SCREWS OR PEM TYPE FASTENERS