Emi-automatic, Riming, Alve – Hale SPV User Manual

Page 7

S

emi-Automatic

P

riming

V

alve

5

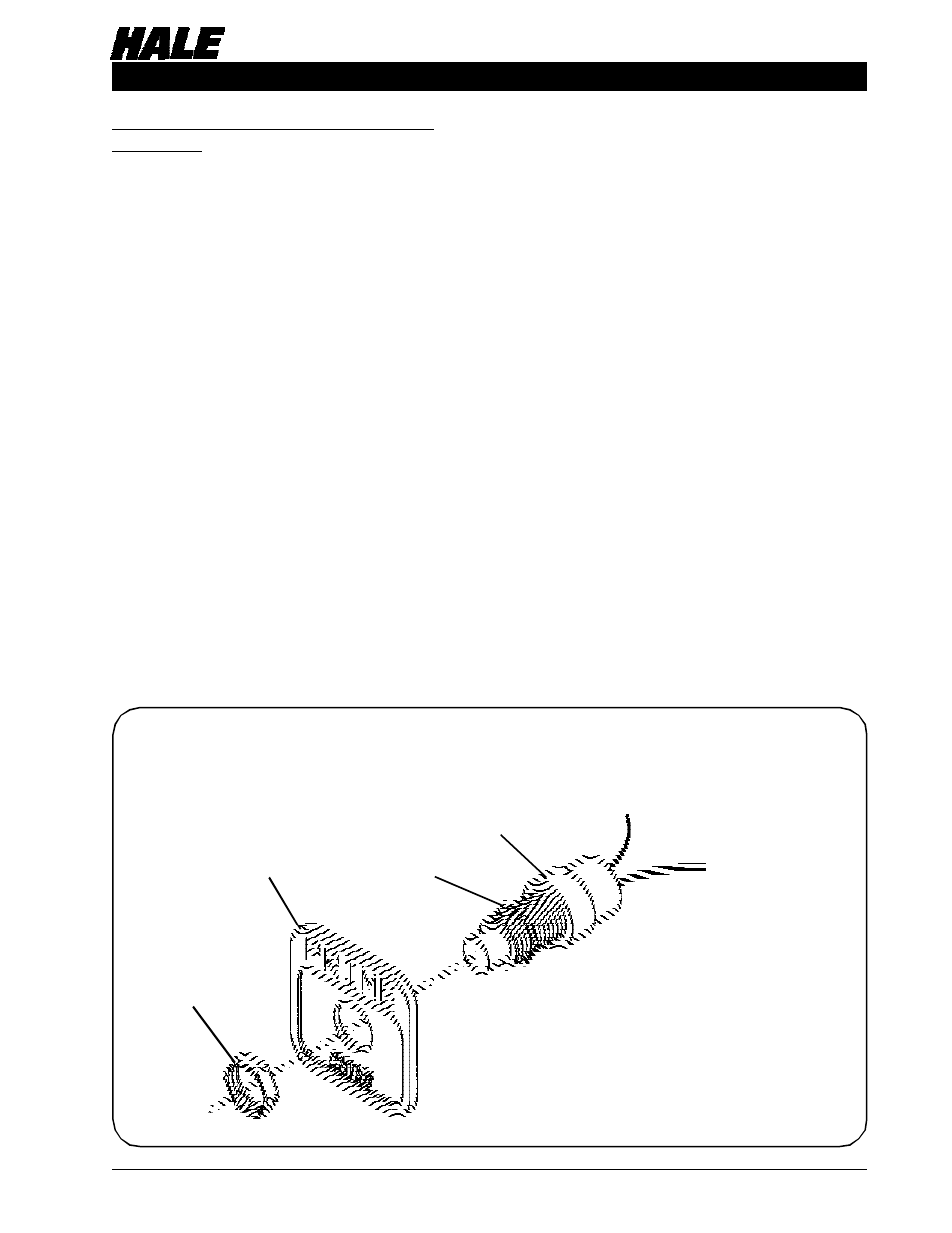

Figure 3. Push-Button Switch Installation

FACE

NUT

PANEL

PLACARD

LOCK

NUT

PUSH-BUTTON

SWITCH

TO PRIMING

PUMP SOLENOID

CONNECTION

(USE MINIMUM 14

AWG WIRE)

TO + BATTERY

POWER

(USE MINIMUM 14

AWG WIRE)

Panel Placard and Push-Button Switch

Installation:

The following procedures shall be used to

install the panel placard and push-button

switch.

WARNING: Disconnect or turn-off master

battery switch prior to service of the

Hale SPV electrical components. Make

sure there is no power at the primer

solenoid before starting service

procedures.

WARNING: Any electrical system has the

potential to cause sparks during

installation, service or repair. Take care

to eliminate explosive or hazardous

environments during installation, service

or repair.

1. Carefully locate the position of the push-

button switch on the operator panel.

2. Drill or punch a 0.64 inch (16 mm)

diameter hole in the panel.

3. Remove the push-button switch from the

packaging and install the locknut on the

mounting neck.

4. Refering to figure 3, Insert the push-

button switch through the 0.64 inch (16

mm) diameter hole from the back of the

operator panel.

5. Place PRIME placard over exposed end

of push-button switch on outside of

operator panel.

6. Install face nut on push-button switch to

hold switch and placard in place.

Tighten locknut and face nut.

7. Using #10 ring terminals on the wire ends,

install minimum 14 AWG type SXL or GXL

wire (SAE J1128) from one switch

terminal to the priming pump solenoid

connection. Secure the ring terminal to

the push-button switch using the screws

provided.

8. Using #10 ring terminals on the wire ends,

install minimum 14 AWG type SXL or GXL

wire (SAE J1128) from the other switch

terminal to the positive battery power.

Secure the ring terminal to the push-

button switch using the screws provided

with the switch.

9. Test operation of the Hale SPV and

priming pump. Conduct vacuum and

hydrostatic tests in accordance with

department procedures, NFPA1901 or

NFPA 1911.