Recommended weekly procedures, Recommended annual procedures, Recommended monthly procedures – Hale MG User Manual

Page 58

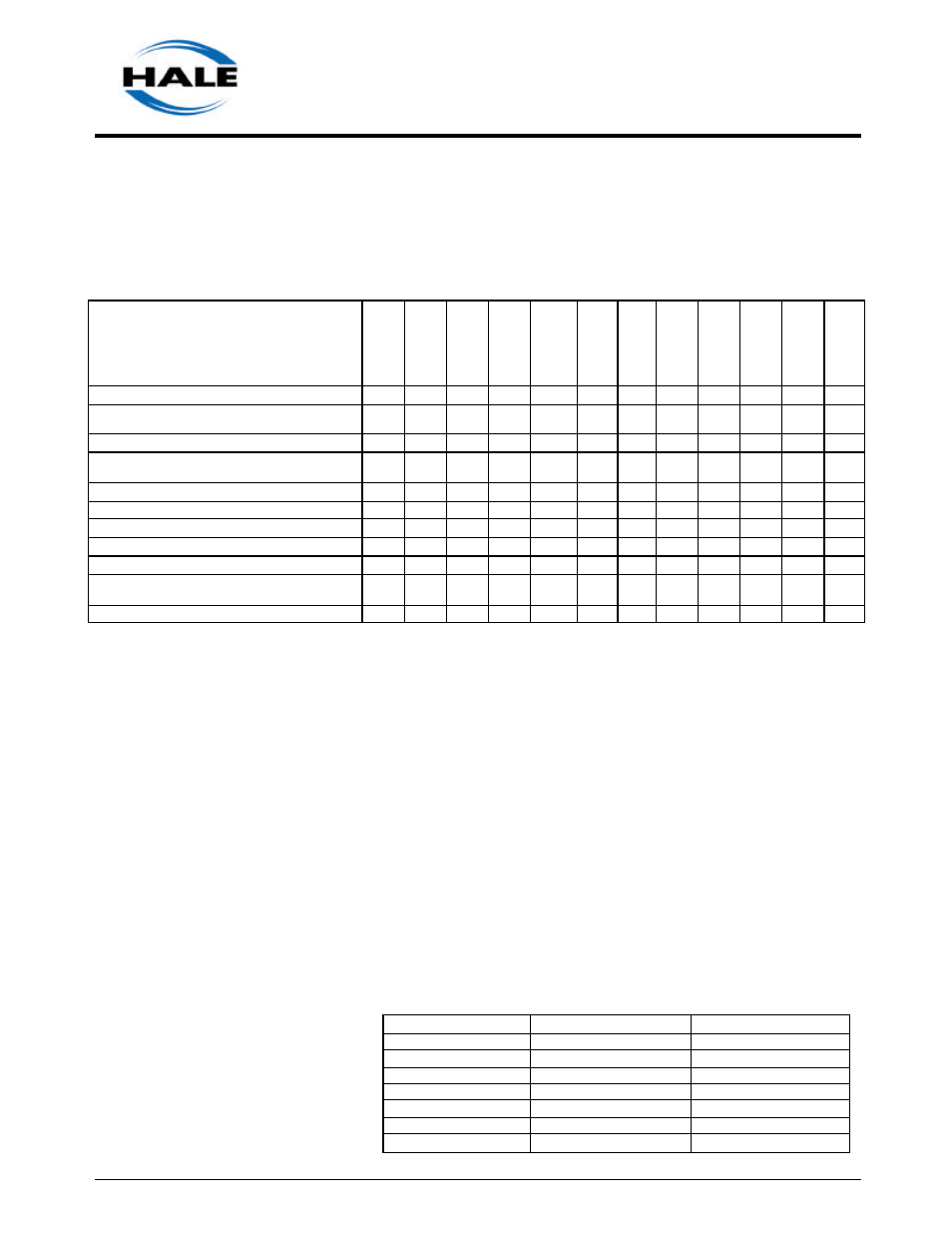

Midship Pump Maintenance Check List

Truck Manufacturer ________________________

Pump Model & Serial Number ________________

Year __________ Unit# _____________________

RECOMMENDED WEEKLY PROCEDURES

q

Test relief valve system or governor at 150, 200, 250 PSIG.

q

Test transfer valve (if applicable).

q

Test the priming system (check lubrication level in priming tank were installed).

q

Lubricate all valves, discharge, suction, hose, drain, and multi-drain.

q

Check pump shift warning indicator lights.

RECOMMENDED

MONTHLY PROCEDURES

JAN

FEB

MAR

APR

MAY

JUN

JUL

AUG

SEP

OCT

NOV

DEC

Complete weekly checks

Lubricate threads on PM relief valve panel

control and check light

Lubricate remote valve controls

Check controlled packing leakage and adjust if

necessary (8 to 10 drops per minute)

Perform dry vacuum test*

Check drive flange bolts to ensure tightness

Lubricate suction tube threads

Clean strainer

Inspect gaskets

Check oil level in pump gearbox; add oil if

necessary

If necessary, replace oil with SAE EP 90 oil

*Per NFPA-1911, 22 inches Hg minimum vacuum: loss not to exceed 10 inches Hg vacuum in 5 minutes.

RECOMMENDED ANNUAL PROCEDURES

q

Complete all previous checks on all questions.

q

Check gauge calibration.

q

Check oil level in AutoLube® assembly (SAE-EP 90 or 80W-90); see operation and maintenance manual

for details.

q

Lubricate power transfer cylinder, power shift cylinder, and shift control valve with vacuum cylinder oil, if

applicable.

q

Change pump gearbox oil and refill (SAE-EP 90 oil or 80W-90).

q

Check individual drain lines from pump to multi-drain to ensure proper drainage and protection from

freezing.

q

Lubricate transfer valve mechanism on two stage pumps. Dry moly spray is preferred.

q

Run yearly standard pump test (per NFPA-1911) to check pump performance levels – chart provided

below.

q

Repacking of pump is recommended every two or three years.

NOTE: The above general recommendations are provided for normal use and conditions. Extreme conditions

or variables may indicate a need for increased maintenance. Good preventative maintenance lengthens pump

life and ensures greater dependability. Consult service or diagnostic chart in operator’s manual for detailed

information.

ANNUAL PUMP TEST RESULTS

Capacity @ 150 PSI

70% Capacity @ 200 PSI

50% Capacity @ 250 PSI

Hose Layout

Nozzle Size

Nozzle Pressure

Gallons Per Minute

Pump Pressure Current Engine Speed

Engine Speed from Original Test Documents

Lift and Suction Hose Size and Number