Hale MG User Manual

Page 16

Muscle Pumps

1-9

Impeller inlets are on opposite sides of the pump to

balance axial forces; discharges are on opposite

sides to balance radial forces.

Qpak and Qflo Pumps

The Hale Qpak and Qflo pump body is a single

piece. Service of the impeller, clearance rings and

mechanical seal is accomplished by removing the

gearbox and rear pump head/bearing housing from

the pump. This can be accomplished without

disturbing discharge or suction piping attached to

the pump.

The Qpak and Qflo pump has two large suction

inlets on the left and right sides. The incoming

water is directed to the impeller through the

suction passages.

A tank suction valve opening, located on the rear

of the Qpak and Qflo pump allows for high flows

from the booster tank. An optional built-in check

valve is available to prevent tank over-

pressurization.

Hale muscle pumps are “manifolded” type pumps

meaning the pump volute, suction manifolding,

and discharge manifolding are cast as one piece.

This one-piece pump design simplifies installation

of the pump and plumbing of the discharge piping.

Discharge valves in the basic pump configuration

can be mounted at either side of the pump body.

However, the manifolded pump body provides

several additional discharge locations (facing front,

back, or up) that can accommodate additional

discharge valves.

Impeller

The impeller provides velocity to the water. This

part is mounted on a shaft that is rotated by the

drive. Water enters the rotating impeller at the

intake (or eye), and is confined by the shrouds and

the vanes mounted in the impeller to build

pressure. The vanes guide water from the inlet to

the discharge and reduce the turbulence of the

spinning water. Vanes curve away from the

direction of rotation so water moves toward the

outer edge. The shrouds form the sides of the

impeller, and keep the water confined to

centrifugal acceleration.

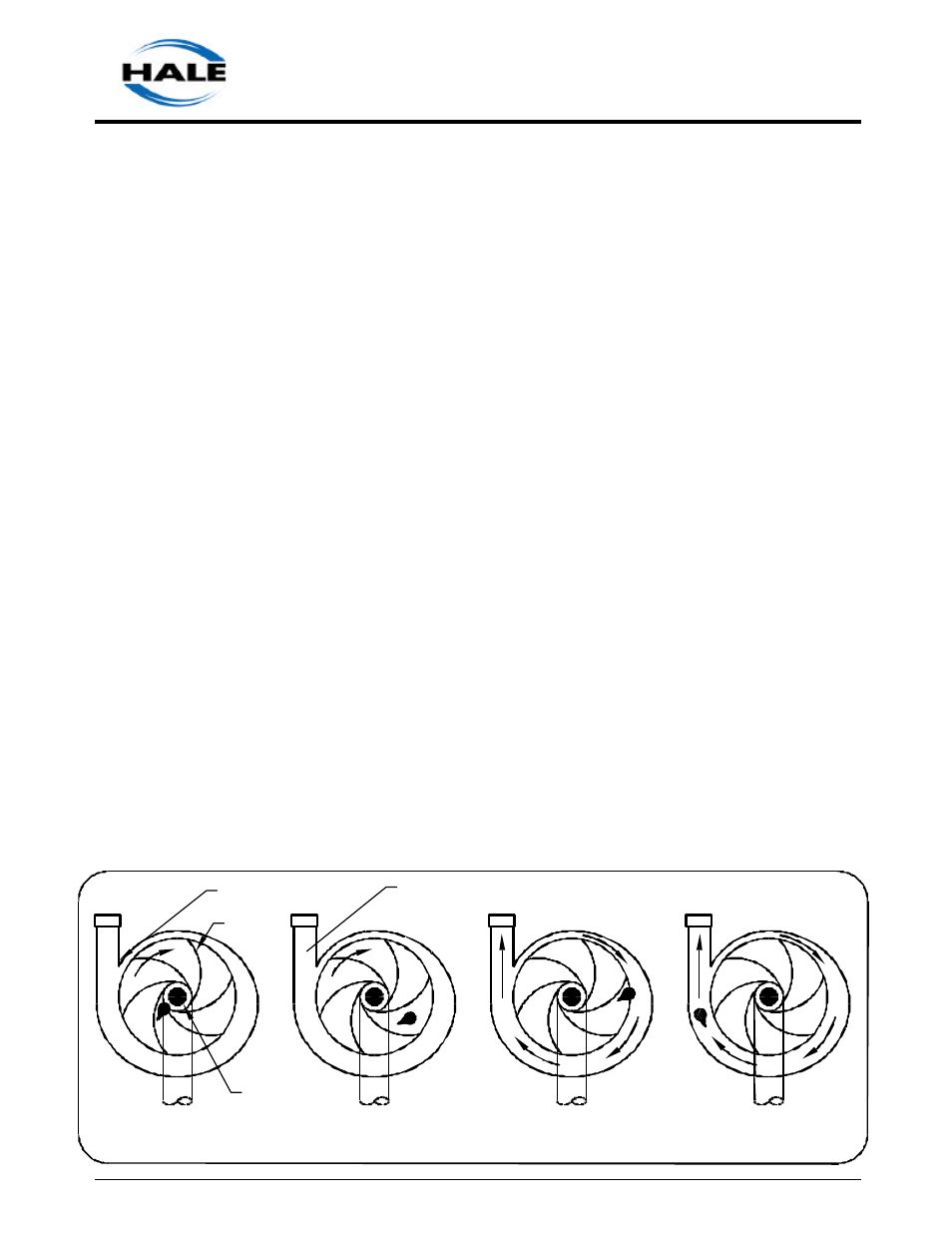

Figure 1-8 traces a drop of water from the intake of

the impeller to the discharge outlet. The impeller is

mounted so that the discharging tube is widest at

the pump outlet. The increasing discharge path,

known as the volute, collects the water at a

constant velocity. A further increase in pressure

and a decrease in velocity take place in the

diffuser.

Clearance Rings

Clearance rings prevent the water that is

pressurized and leaving the pump volute from

returning to the intake of the impeller. Centrifugal

pumps have clearance rings at the impeller intake

to prevent leakage. This is accomplished by limiting

the radial clearance between the spinning impeller

and the stationary clearance ring. Refer to figure 1-7.

Figure 1-8. Impeller Operation

INTAKE

DISCHARGE

CUT WATER

EYE

VANES

DIFFUSER