Hale 2CBP User Manual

Page 8

Sec I- 4

Introduction

Booster Pumps

confined to increase acceleration and pressure.

The discharging tube is widest at the pump

outlet. The increasing discharge path, known

as the volute, collects the fast moving water and

converts the water's velocity into pressure.

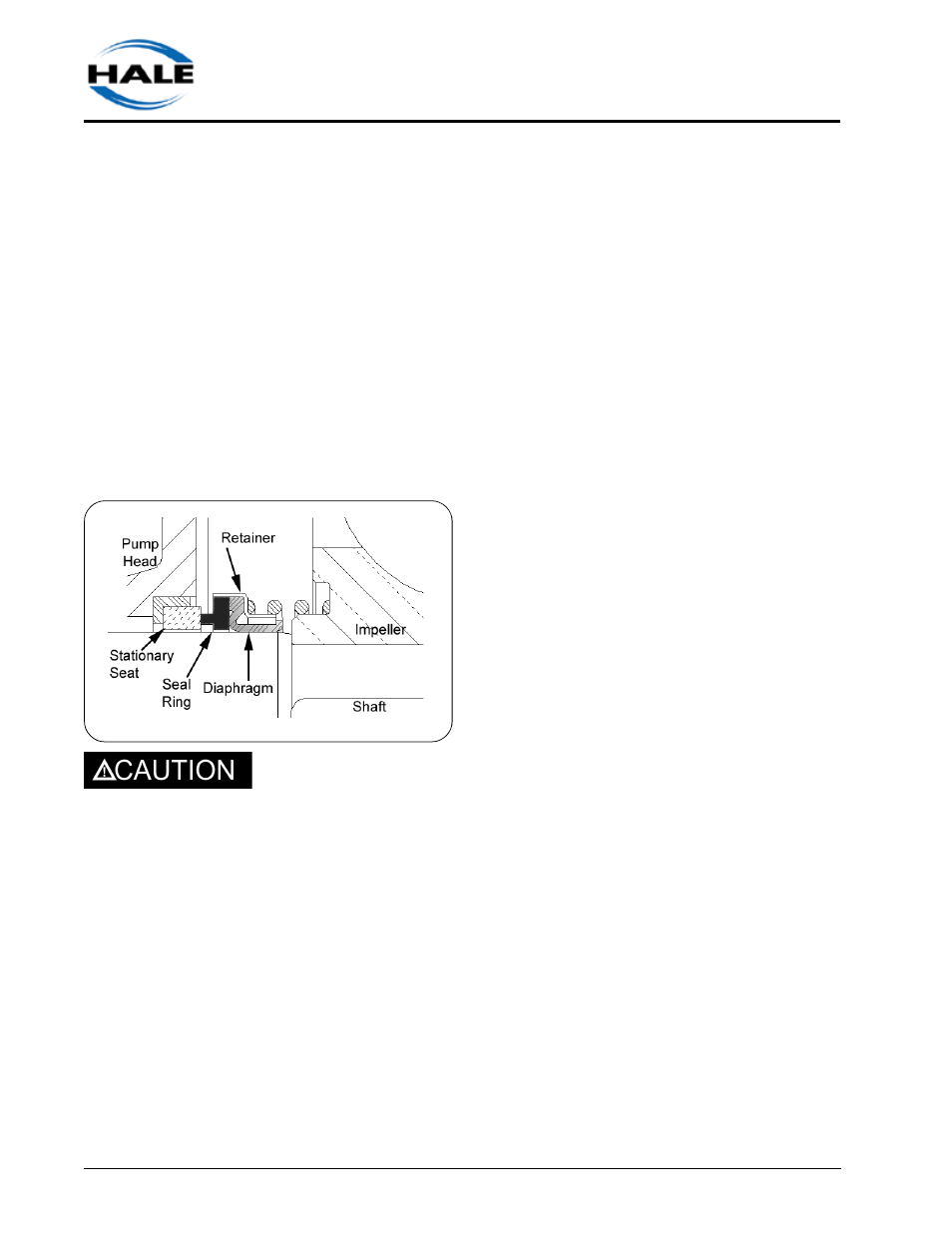

Mechanical Seal

The mechanical seal is common to all Hale

booster pumps. Shown in figure 1-6, a

stationary seat is in constant contact with a

rotating seal ring to prevent leakage. The

sealing diaphragm is made of a rubber

elastomer specifically designed for high-

temperature operations.

If a pump is operated without water for

extended periods, or without discharging water,

it may overheat. This may damage the

mechanical seal or the drive mechanism.

Gearbox

The gearbox is typically constructed of fine

grain alloy cast iron. Inside the gearbox (Figure

1-5) a gear set and input drive shaft made of

heat-treated nickel steel, transfers engine power

to the impeller. Hale offers a variety of pump

gear ratios to accommodate a wide range of

end-user and apparatus manufacturer

requirements based on the pump's intended

use, horsepower and speed rating of the

engine, and the torque rating of the

transmission PTO.

Pump Drives

There are four common types of booster pump

drives used on fire fighting apparatus:

1. The most common drive is the PTO mounted

on the truck transmission or four-wheel drive

transfer case which allows for pump and roll

operation.

2. A stand-alone drive with separate engine

(auxiliary engine).

3. The truck chassis engine crankshaft (front-

engine PTO).

4. Hydraulic Motor

Hale booster pumps are built to produce the

volumes and pressures shown on their

respective performance curves. However, the

volumes and pressures safely obtainable are

dependent on the torque capacity of the

apparatus transmission or transfer case, power

takeoff and the pump drive line. In most cases,

the torque rating of the PTO determines

maximum pump performance.

The apparatus builder can give various pump

performance spots that will define the torque

limit of the PTO in terms of GPM and PSI.

When pumping continuously, care should be

taken not to overheat the apparatus' PTO,

transmission or transfer case.

HALE Power Takeoff Pumps

Hale booster pumps are available for either

engine rotation or opposite engine rotation PTO

operation. Additionally, the pump can be

configured to discharge in a variety of positions.

Since some PTOs match engine rotation and

some turn opposite of the engine rotation, each

pump model can be built to match the rotation

of the PTO.

Figure 1-6: Mechanical Seal