Hale 2CBP User Manual

Page 7

Introduction

Sec I-3

Booster Pumps

Two-Stage Booster Pump

The Hale Two-Stage Booster Pump (2CBP)

has two impellers connected in series for high-

pressure operation. The output of the first

impeller is supplied to the intake of the second

impeller. This second impeller adds additional

pressure and directs the water to the discharge.

Since the two-stage booster pump only

operates in series, the final water pressure is

the inlet pressure plus the pressure added by

both impellers. The volume of water delivered

at the discharge, however, is the same. Figure

1-4 shows the flow of water through a Hale

2CBP booster pump.

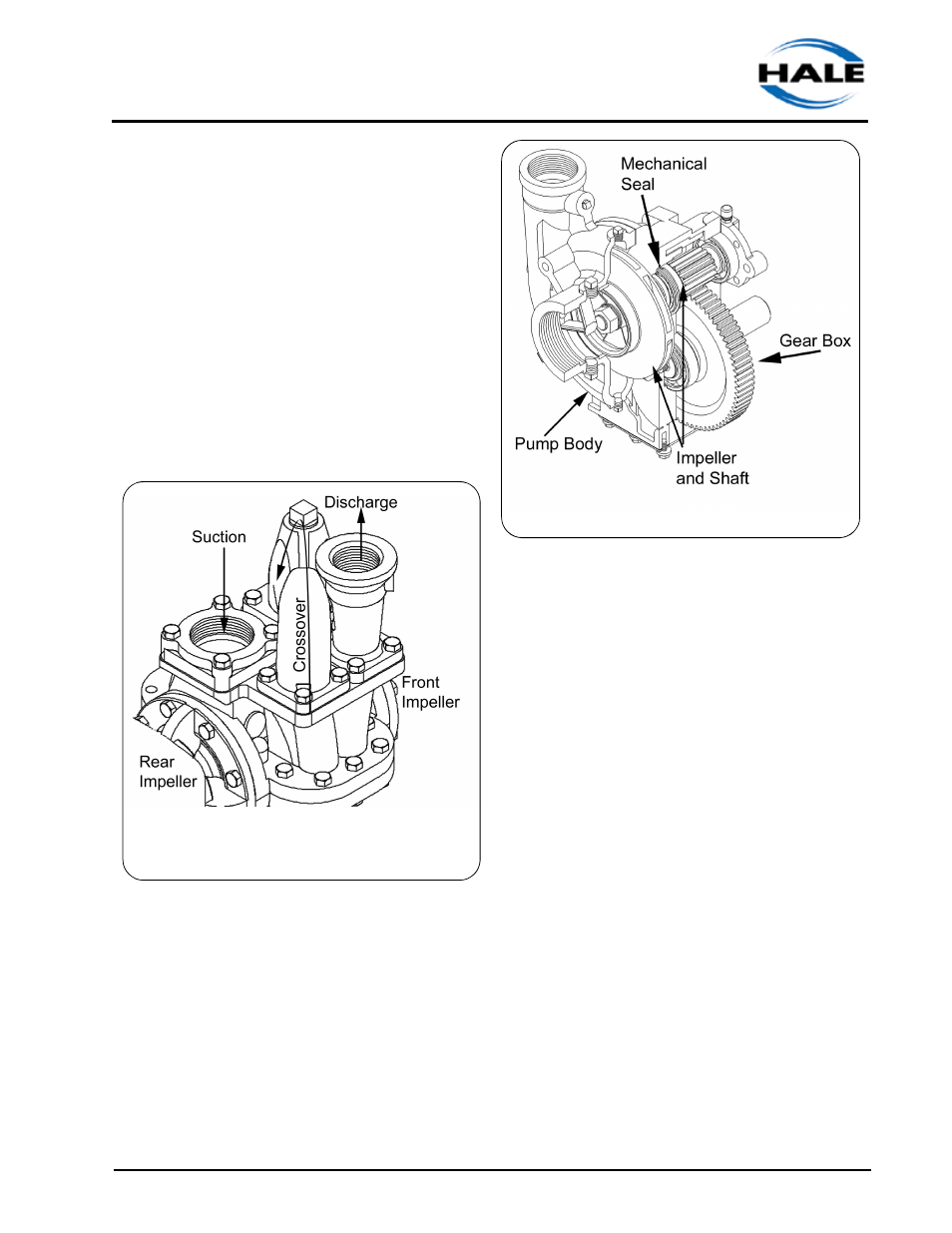

COMPONENTS OF A BOOSTER

PUMP

Booster pumps are made up of:

o

Pump Body

o

Impeller and Shaft Assembly

o

Mechanical Seal

o

Gearbox

Figure 1-5 shows these basic parts of a Hale

booster pump. These parts are briefly

described in the following section.

Pump Body

The Hale single-stage booster pump body is a

single-piece casting. Service of the impeller,

clearance rings, and mechanical seal is

accomplished by removing the pump body from

the pump head and gearbox.

The pump body is constructed from fine grain

cast iron. For areas where salt water is

commonly used, a bronze version of the booster

pump is available.

Impeller and Shaft Assembly

The impeller provides velocity to the water. The

impeller is made of high quality bronze and is

mounted on a stainless steel shaft that is

rotated by the gearbox. Water enters the

rotating impeller at the intake (or eye). The

vanes guide water from the inlet to the

discharge. Vanes curve away from the direction

of rotation so water moves toward the outer

edge (see Figure 1-2). The shrouds form the

sides of the impeller and keep the water

Figure 1-4: 2-Stage waterflow

(Top half of 2CBP shown only.)

Figure 1-5: Parts of the Hale Booster Pump