Hale 2CBP User Manual

Page 11

Introduction

Sec I-7

Booster Pumps

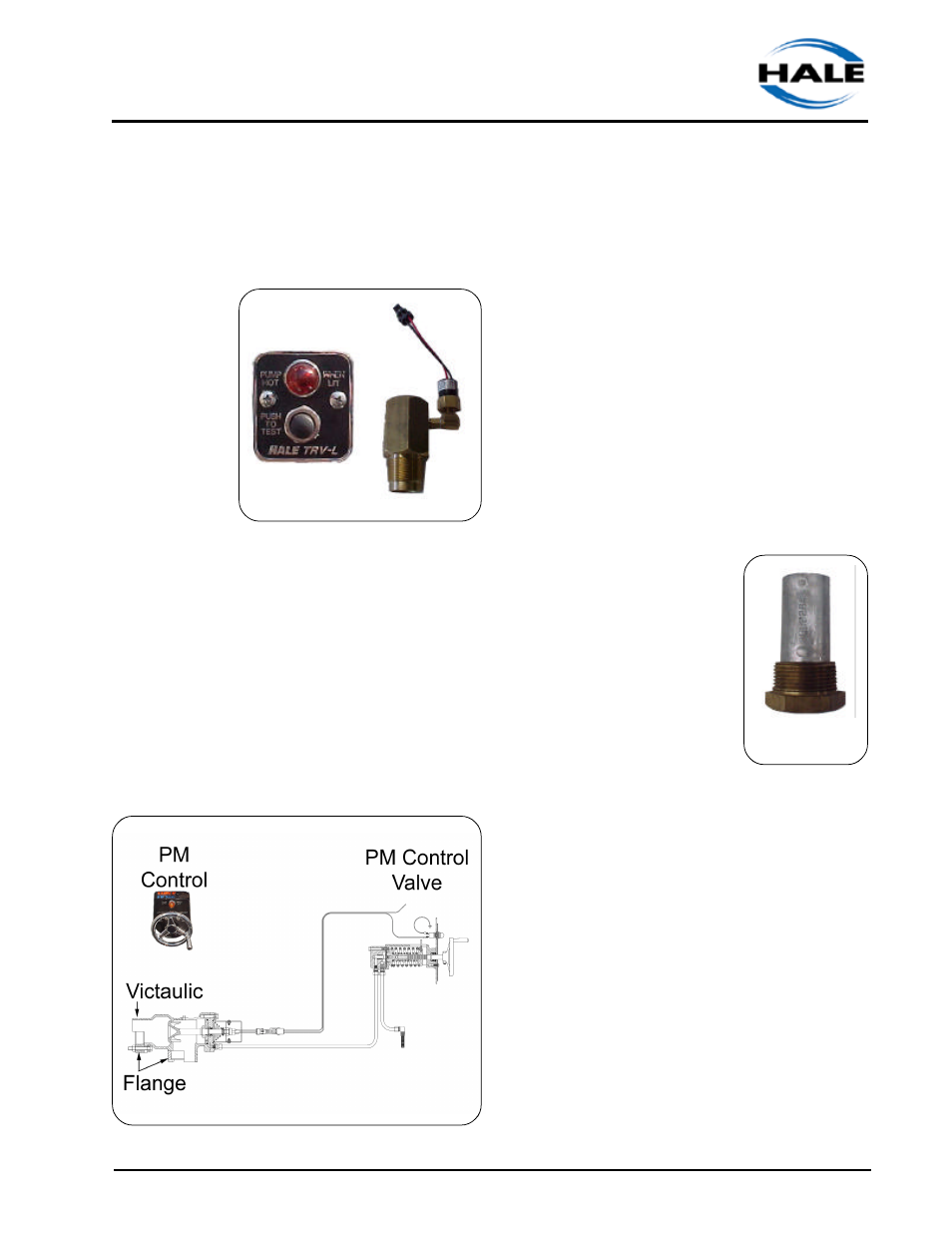

applied to the diaphragm in the PM Control

valve. As the pressure on the diaphragm

increases beyond the set point, the stem will

move off its seat, allowing pump pressure to

push on the piston in the relief valve. The

pressure on the piston will cause the relief valve

seat to lift

allowing

excess

pressure to

dump back to

the pump

suction. After

the pressure

equalizes, the

piston returns

to the closed

position.

The amber

indicator light on the PM control illuminates

when the relief valve is open.

Thermal Relief Valveb (TRV)

The Thermal Relief Valve (see Figure 1-11)

protects the pump from overheating. The

optional TRV unit can be attached to the

discharge piping either by flange mounting or 1-

1/4" NPT threaded connection (38 mm for the

TRVM). The valve monitors the temperature of

the water in the pump. When the temperature

exceeds 120

o

F (48.9

o

C), the valve

automatically opens and depending on the

installation, discharges a small amount of water

either to the ground or into the water tank

allowing cooler water to enter. After the

temperature returns to a safe level, the valve

closes. The TRV will flow up to 1-2 GPM (3-7

LPM).

TRV-L Kit

The TRV-L kit includes a chrome panel placard

with a warning lamp, lamp test button, and a

preassembled wiring harness. The light

illuminates whenever the TRV is open and

discharging water. An optional buzzer provides

audible warning. The buzzer mounts on the

operator panel.

Anodes

The Hale Anode System

helps prevent damage

caused by galvanic corrosion

in the pump. Galvanic action

pits the pump and pump

shaft material. The popularity

of non-corrosive water tanks

and piping has increased this

type of corrosion in today’s

fire pumps. The Hale Anode

System is a sacrificial metal, which helps

prevent corrosion. The anode will fit on any

Hale truck mounted pump, regardless of age or

model. It is designed to be easily installed

requiring four bolts and a gasket. Total time to

install is just fifteen minutes, yet it will provide

years of protection for the pump. The Anode kit

is designed for installation in the standard Hale

115 series flange opening. On fabricated

manifolds and similar applications, the installer

is to provide 1-1/4 NPT openings and install

anodes directly. It is recommended that one

anode be installed on the suction side and one

on the discharge side.

Figure 1-11: TRV-L

Figure 1-13:

Hale Anode

Figure 1-12: