Hale 2CBP User Manual

Page 26

Booster Pumps

Sec III- 6

Preventive Maintenance

Refer to local procedures for pump testing

procedures and practices.

For Pitot gauge accuracy, the nozzle pressures

should be between 30 and 85 PSIG. See the

chart on the facing page for nozzle flow and

pressures. Table 3-3 provides GPM for various

nozzle sizes.

Because NFPA standards specify both GPM

and pressure, it is usually necessary to restrict

the flow somewhat to build up the pump

pressure. In normal pumping, this restriction

would be caused by the friction loss in the lines.

However, depending on line loss alone would

require a large amount of hose for some tests.

It is common practice to use 50 to 100 feet of

hose and gate the discharge valves as required

to maintain pressure.

Performance Testing Procedure

Note: The NFPA standards require a 10 percent

reserve in pressure at the capacity run when the

apparatus is delivered.

1. Check the relief valve according to the Relief

Valve Testing procedure under Weekly

Maintenance.

2. Perform steps 2 and 3 of the Post-Operation

Maintenance procedures in this section.

3. Run the standard pump test in accordance

with NFPA standards to check pump perfor-

mance.

4. Pumps rated below 750 GPM are tested for

an hour per NFPA 1901, 14-13.2.3.2. Run

the engine for 20 to 30 minutes to stabilize

the engine temperature. Then run the pump

for 20 minutes at capacity, 10 minutes at 70

percent capacity, and 10 minutes at 50

percent capacity.

5. If the apparatus does not reach performance

levels, refer to the Diagnostic/Service chart

in Section IV.

6. Compare the results of this test to those from

when the apparatus was delivered. It may

be that the apparatus did not show the 10

percent reserve at delivery. If the apparatus

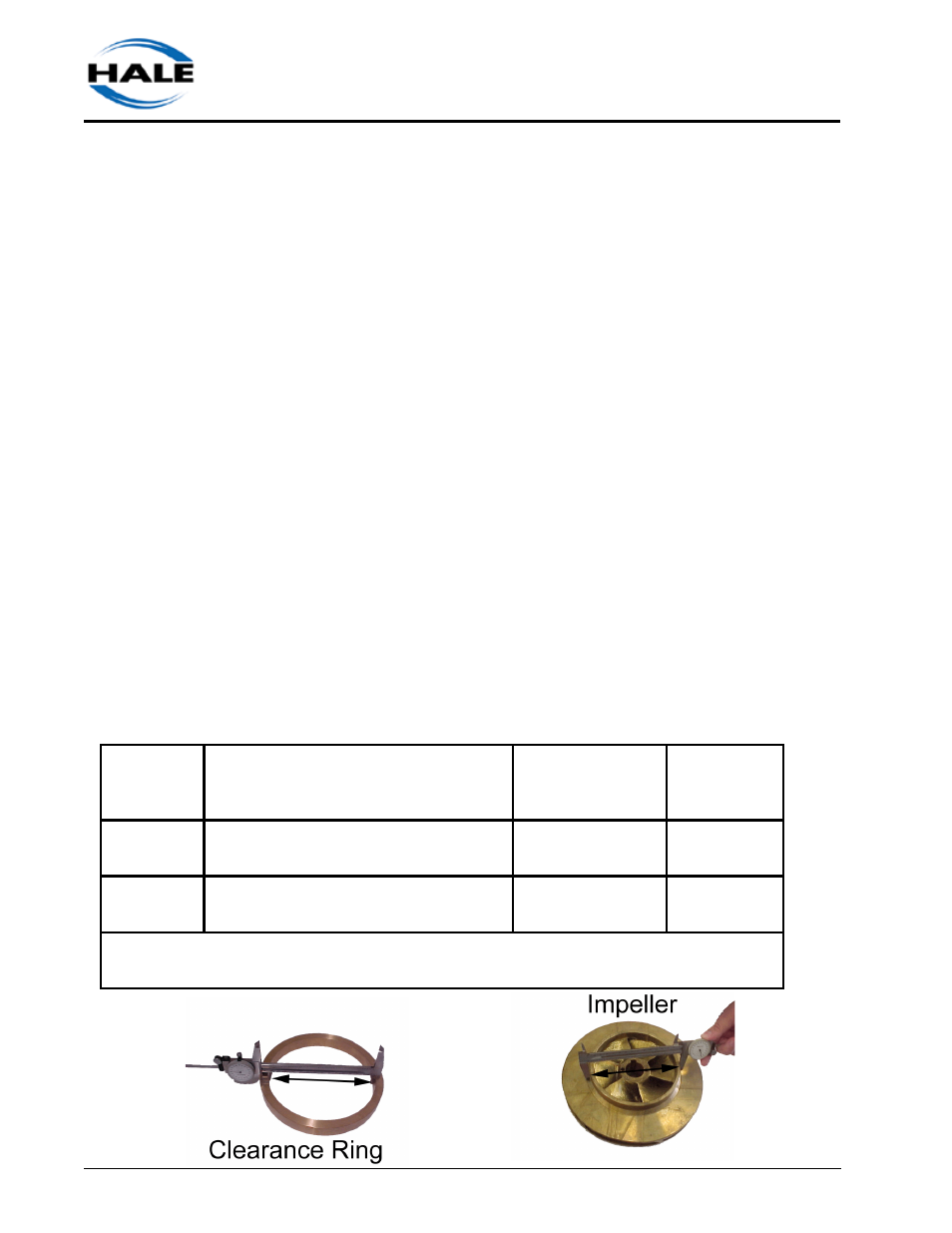

Pump Model

Clearance Ring Inner Diameter (pressed

into pump body or pump head)

IN (MM)

Impeller Hub Outer

Diameter

Permissible

Clearance

CBP

3.6312-3.6326

(92.232-92.268)

3.620-3.622

(91.948-91.999)

.009-.013

(.227-.330)

AP

4.770-4.777

(121.158-121.336)

4.760-4.758

(120.904-120.853)

.012-.017

(.305-.432)

Table 3-2: Impeller and Clearance Ring Diameters and Clearance Values