Ap pump disassembly – Hale 2CBP User Manual

Page 41

Maintenance and Repair

Booster Pumps

Sec V- 5

AP PUMP DISASSEMBLY

AP Pump Body

The pump body can be removed from the

gearbox assembly providing access to the

internal parts without disconnecting the drive

unit.

Remove AP Pump Body

1. Disconnect the suction, discharge, cooling

lines, and any electrical wiring. Disconnect

mounting brackets as required. Match mark

the pump body and pump head to ensure

proper alignment during reassembly.

2. Remove the 7/16 - 14 X 1" cap screws that

hold the pump body assembly to the pump

head.

3. Remove the pump body from the pump

head, do not damage the brass clearance

rings or impeller.

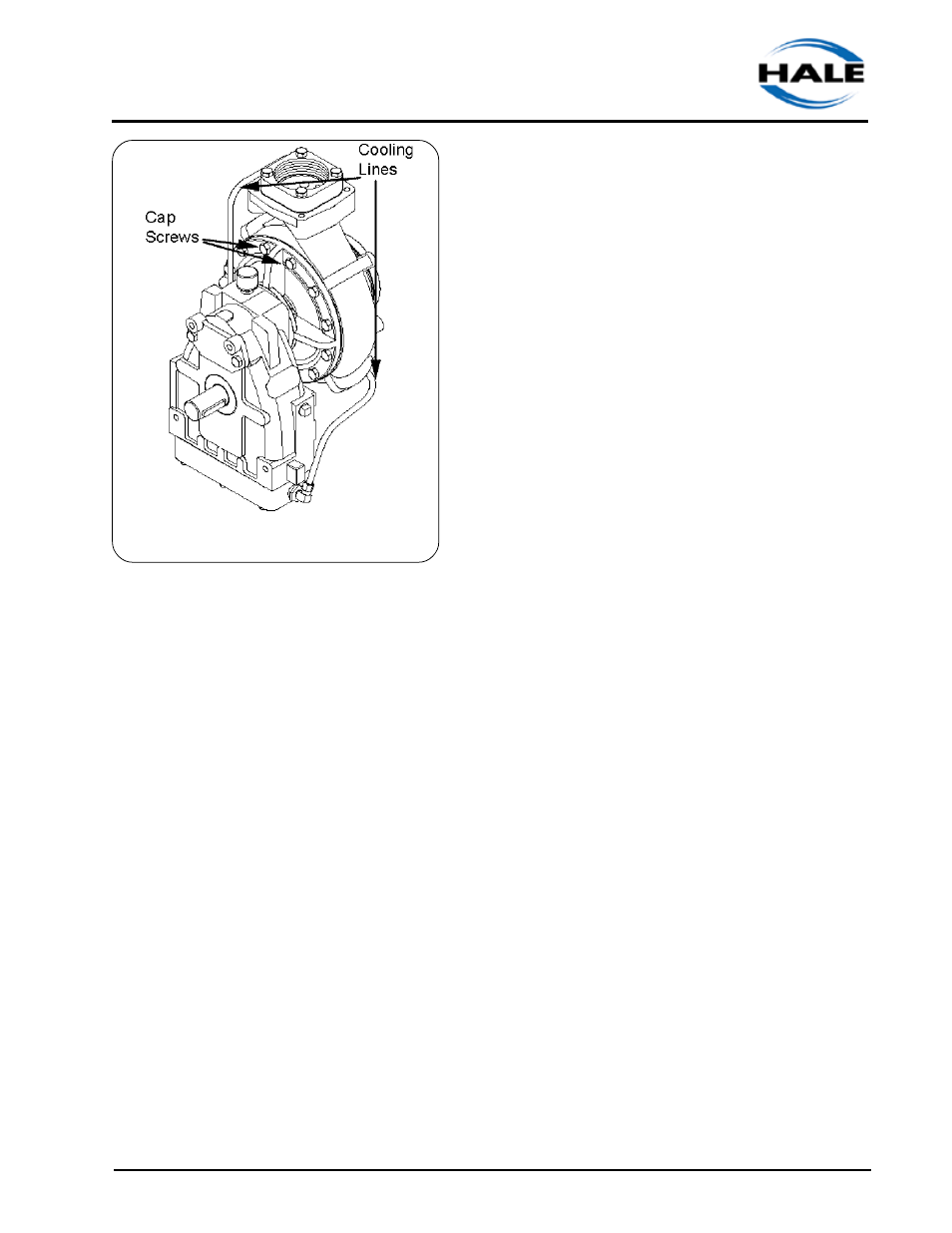

Figure 5-4: AP Pump and

Gearbox Assembly

4. Remove all remaining gasket material from

the mating surfaces of the pump body and

pump head.

Install the Pump body

1. Use a press to install the clearance ring in

the pump body.

2. Apply a small amount of grease to the

gasket and align on the pump body.

3. Install the pump body onto the pump head,

do not damage the clearance rings or

impeller.

4. Apply Loctite™ 242 (or equal) to the threads

and install the 7/16-14 UNC x 1 cap screws

that hold the pump body to the pump head.

Refer to Table 5-2 for recommended torque

values for fastener size and material.

5. Reconnect all piping and tubing.

6. Return the apparatus to service.

AP IMPELLER AND MECHANICAL SEAL

Remove AP Impeller

1. Remove the pump body as described above.

2. Remove the cotter pin that secures the

impeller nut.

3. Hold the impeller with a strap wrench, and

remove the impeller nut.

4. To avoid warping the impeller, use wedges

and a proper puller to pull the impeller from

the pump shaft.