Hale 2CBP User Manual

Page 53

Maintenance and Repair

Booster Pumps

Sec V- 17

o

Apply a generous coating of PAC-EASE

Rubber Lubricant Emulsion (or equal) to the

outside of the stationary seat.

o

Slide the stationary seat over the pump

shaft and fit the stationary seat of the

mechanical seal into the pump head.

o

Push the stationary seat into the pump

head bore using a soft clean pusher tube.

The stationary seat must be seated in the

pump head.

o

Clean the pump shaft with alcohol

swabs.

o

Apply a generous coating of PAC-EASE

Rubber Lubricant Emulsion (or equal) to the

seal diaphragm. Without touching the

carbon seal ring, push the carbon seal ring,

diaphragm, and retainer onto the shaft with

the pusher tube.

o

Keep the shaft well lubricated and verify

the carbon seal ring seats against the

stationary seat. If binding occurs, apply

additional lubricant. Slide the spring and

cupwasher (supplied with the seal) onto the

shaft.

5. Insert the impeller key in pump shaft then

install rear impeller, center bearing, front

impeller and bearing washer.

6. Apply Loctite™ 640 to pump shaft threads.

Secure impellers in place using the impeller

nut. Torque the impeller nut to 125 ft lbs (169

Nm).

7. Apply a light coat of grease to the pump

head gasket and align the gasket on the

pump head.

8. Lift the lower pump body into place and

secure with screws through pump head. (DO

NOT TIGHTEN SCREWS).

9. Apply a light coating of grease to the pump

body gasket and align the gasket on the

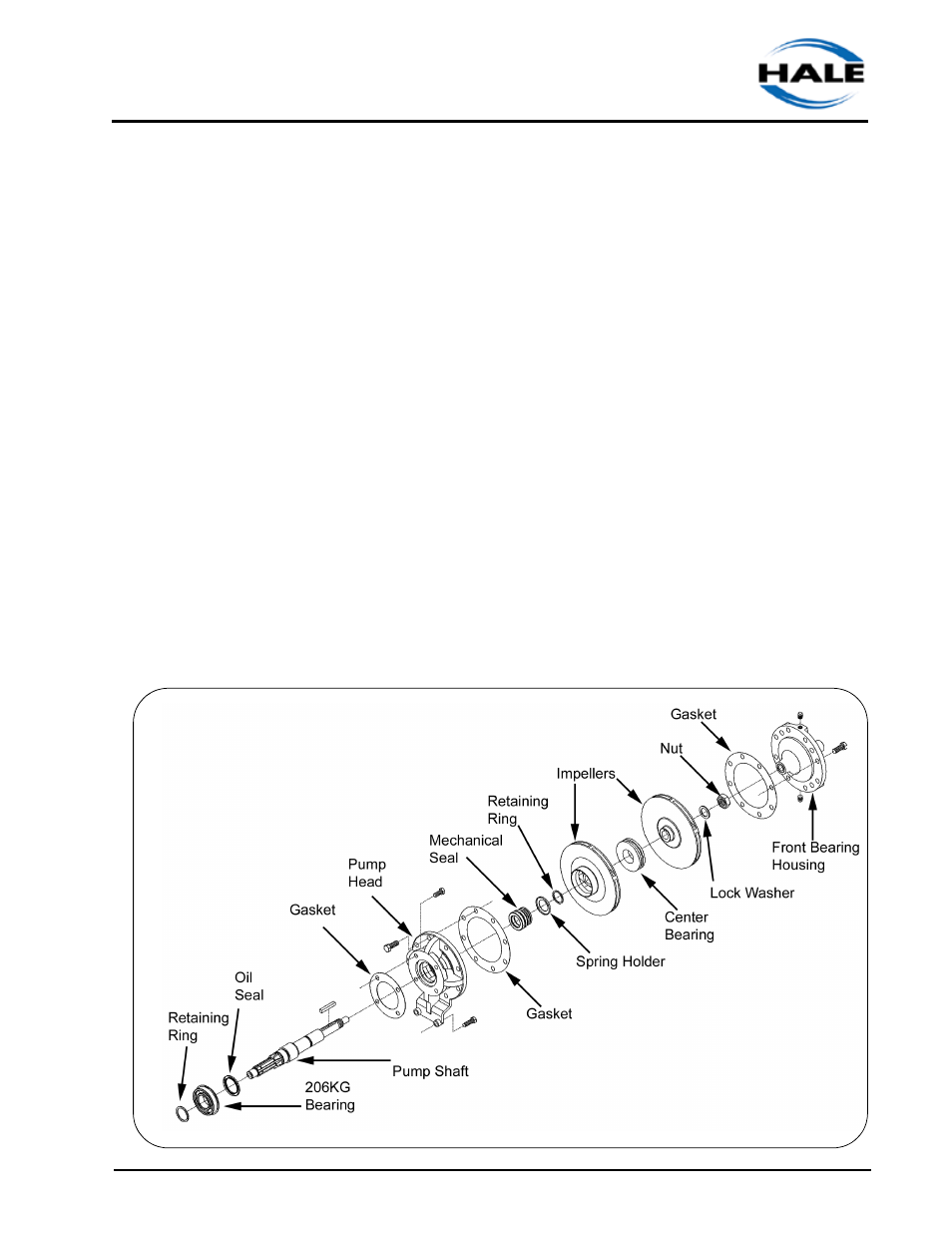

Figure 5-12: 2CBP Pump