Section 6 pump installation, Overview, Frame mounting – Hale 4DK Series User Manual

Page 41: Driveline issues, Figure 22: 4dk series pump installation, Overview frame mounting driveline issues, Important

Manual p/n: 029-0020-79-0

41

4DK Series Pumps

SECTION 6 PUMP INSTALLATION

OVERVIEW

This section provides guidelines and recommen-

dations for installing a Hale 4DK pump and

gearbox into a truck chassis.

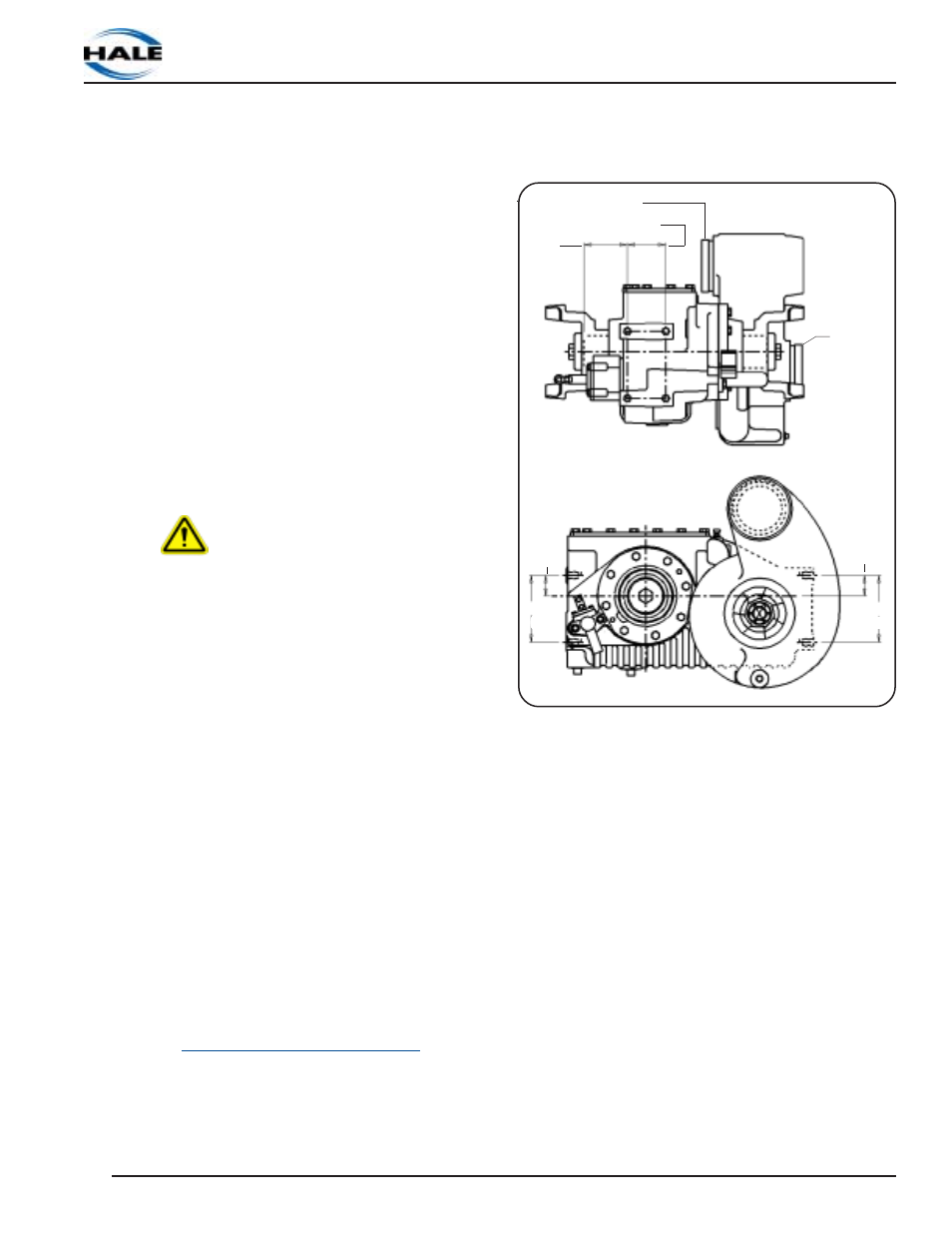

FRAME MOUNTING

The 4DK gearbox is mounted using four 5/8-11

bolts on either side of the gearbox. See Figure

22: "4DK Series Pump Installation" in the next

column. All eight bolt holes are tapped 1"

(25mm) deep.

IMPORTANT !

TO FULLY SUPPORT THE GEARBOX AND PUMP,

USE ALL EIGHT BOLT HOLES.

DRIVELINE ISSUES

Due to the increasing sophistication of fire appa-

ratus and truck design, there has been an in-

crease in the number of reported driveline prob-

lems. These problems include: drive shaft failure,

loosened drive ends on pump gearboxes, broken

mounting brackets, driveline joint or slider wear,

bearing wear on pumps or rear axles, and vibra-

tions at specific road speeds. While the inci-

dence of these problems is low, they are expen-

sive to fix yet easy to avoid.

It is critical to use computer driveline analysis

software, such as Dana’s “The Expert,” during

driveline layout. Dana’s software is available free

on the World Wide Web at:

http://www2.dana.com/expert.

While using the software, make sure to perform

three separate driveline analyses:

❑

Front drive shaft assembly

❑

Rear drive shaft assembly

❑

Total system

This ensures individual shaft cancellation and

correct phasing.

When performing calculations, strive to achieve

the lowest driveline torsional and inertial vibra-

tions, making sure to avoid severe driveline

angles. Be conservative and always err on the

side of SAFETY. Always measure the drive shaft

after construction to make sure it matches the

computer design.

Remember the following points while designing a

driveline:

❑

Problems can occur with our without

noticeable vibration.

Figure 22: 4DK Series Pump Installation

3.72"

(95mm)

3.25" (83mm)

4" (102mm) Victaulic

Discharge

4" (102mm)

Victaulic Suction

1.75"

(45mm)

5.75"

(146mm)

5.75"

(146mm)

1.75"

(45mm)