Section 4 troubleshooting, Caution – Hale 4DK Series User Manual

Page 17

Manual p/n: 029-0020-79-0

17

4DK Series Pumps

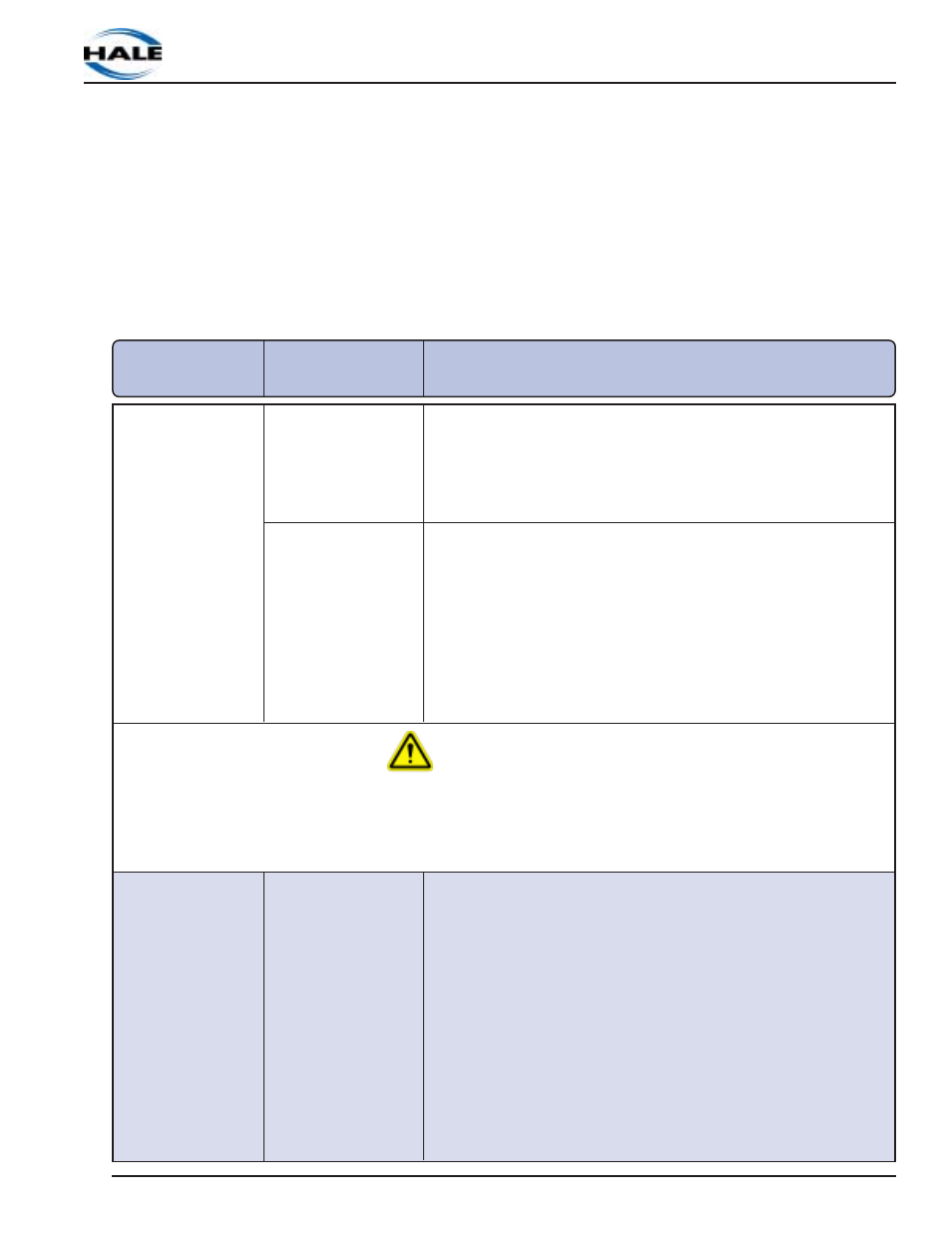

SECTION 4 TROUBLESHOOTING

Table 4-1 lists the Conditions, Possible

Causes and Suggested Corrective Action

measures. Before calling Hale Products or a

Hale authorized parts service center for

assistance, eliminate problem causes using

the following table.

If you cannot correct a problem, please have the

Model and Serial numbers ready prior to calling the

Hale Customer Service Technician Department for

assistance – Customer Service telephone number:

610-825-6300.

SUGGESTED CORRECTIVE ACTION

CONDITION

POSSIBLE

CAUSE

PUMP WILL

NOT

ENGAGE

Automatic trans-

mission with

power shift system

Insufficient air in

shift system

Air leaks in shift

system

●

Repeat recommended shift procedures with transmission in

NEUTRAL position. (See ‘Operating Procedures’ on page 11.)

●

Release brake system momentarily. Then reset and repeat

recommended shifting procedures. (See ‘Operating Proce-

dures’ on page 11.)

●

Release brake system momentarily. Then reset and repeat

recommended shifting procedures. (See ‘Operating Proce-

dures’ on page 11.)

●

Check for leaks in system. Employ manual override proce-

dures if necessary. See Emergency Pump Shift Procedures,

beginning on page 13.

●

Attempt to locate and repair leak(s). Leakage, if external, may

be detected audibly. Leakage could be internal and not as

easily detected.

CAUTION !

SOME VEHICLES MAINTAIN AIR ON THE SHIFT CYLINDER CONTINUOUSLY REGARDLESS OF

TRANSMISSION SETTING, AND SOME ONLY HAVE AIR APPLIED WHEN THE VEHICLE TRANSMIS-

SION IS IN NEUTRAL. USE CAUTION IN SERVICING. DO NOT LEAVE THE CAB AFTER SHIFTING

THE PUMP UNLESS THE SHIFT INDICATOR LIGHT IS ON, OR A SPEEDOMETER READING IS NOTED.

PUMP LOSES

PRIME OR WILL

NOT PRIME

Chart continued on

next page

Suction lifts too high

Blocked suction

strainer

Suction

connections

Air trapped in

suction line

●

DO NOT attempt lifts exceeding 22' (6.7m) except at low

elevation.

●

Remove obstruction from suction hose strainer.

●

Clean and tighten all suction connections. Check suction

hose and hose gaskets for possible defects. Repair and/or

replace.

●

Avoid placing any part of the suction hose higher than the

suction intake. Suction hose should be laid with continuous

decline to fluid supply.